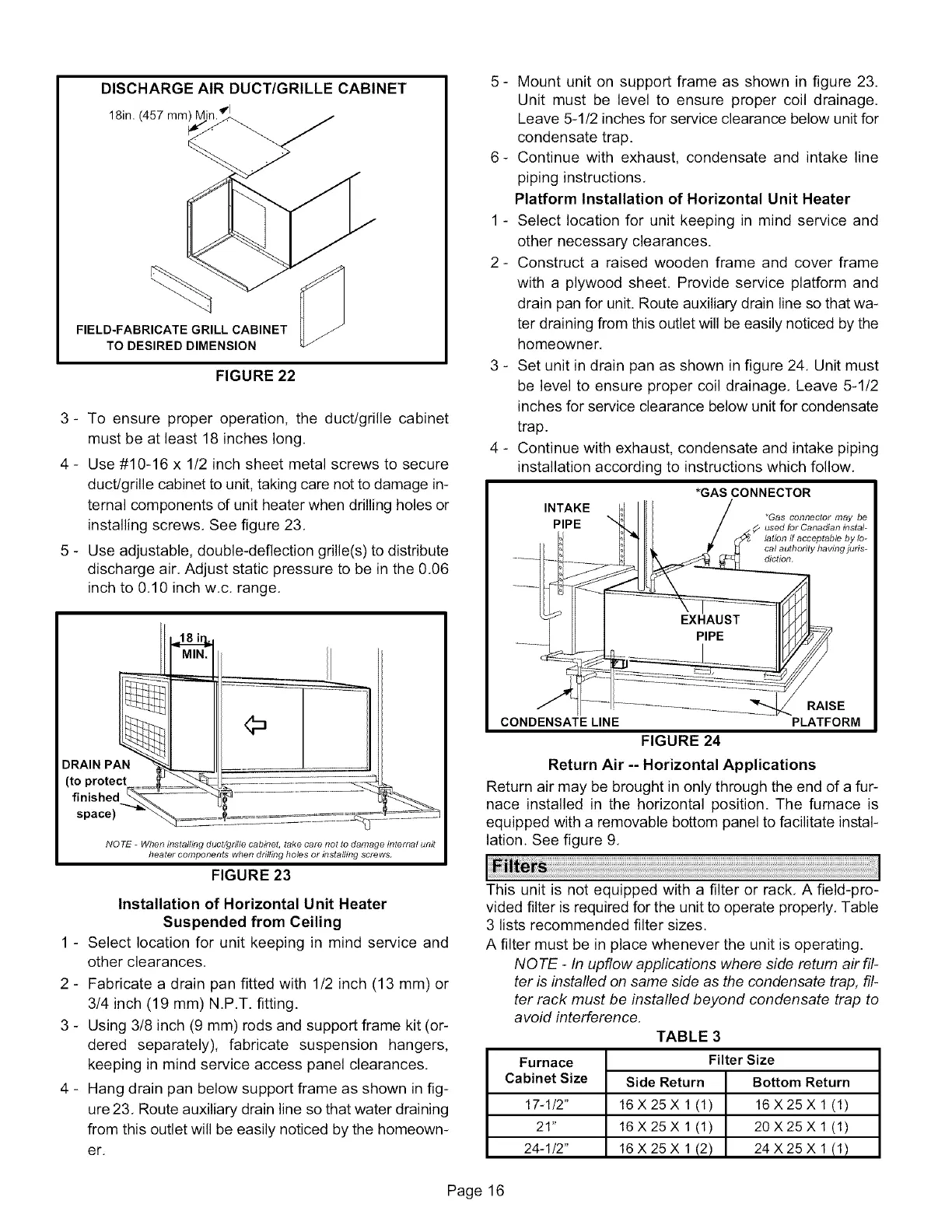

DISCHARGE AIR DUCT/GRILLE CABINET

18in. (457 mm) k ql

FIELD-FABRICATE GRILL CABINET

TO DESIRED DIMENSION

FIGURE 22

3- To ensure proper operation, the duct/grille cabinet

must be at least 18 inches long.

4 - Use #10-16 x 1/2 inch sheet metal screws to secure

duct/grille cabinet to unit, taking care not to damage in-

ternal components of unit heater when drilling holes or

installing screws, See figure 23,

5 - Use adjustable, double-deflection grille(s) to distribute

discharge air, Adjust static pressure to be in the 0,06

inch to 0,10 inch w,c, range,

NOTE - Wtlen installing duct/grille cabinet, take care not to damage internal unit

beater components when drilling holes or instalhng screws.

FIGURE 23

Installation of Horizontal Unit Heater

Suspended from Ceiling

1 - Select location for unit keeping in mind service and

other clearances.

2 - Fabricate a drain pan fitted with 1/2 inch (13 mm) or

3/4 inch (19 mm) N.P.T. fitting.

3 - Using 3/8 inch (9 mm) rods and support frame kit (or-

dered separately), fabricate suspension hangers,

keeping in mind service access panel clearances.

4 - Hang drain pan below support frame as shown in fig-

ure 23, Route auxiliary drain line so that water draining

from this outlet will be easily noticed by the homeown-

er,

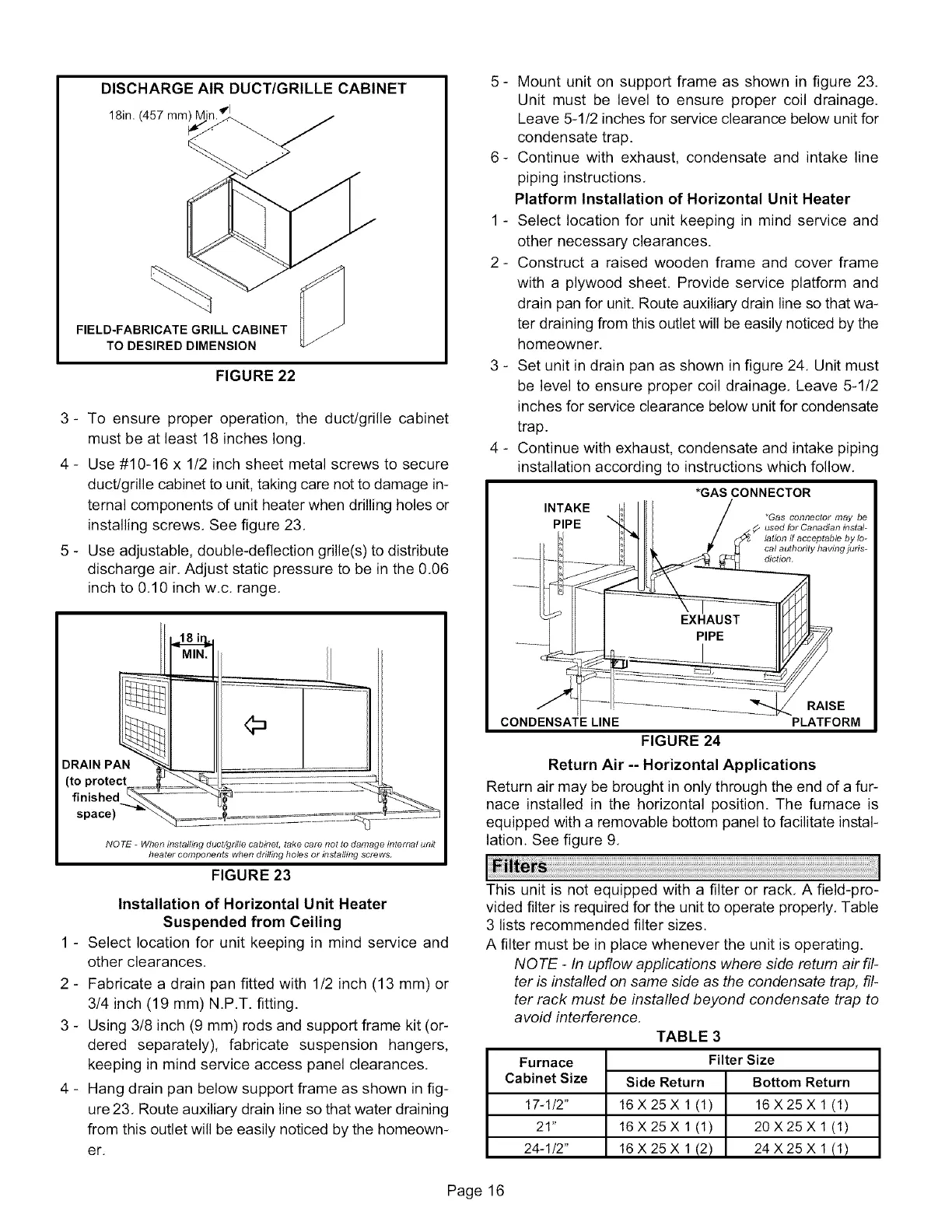

5 - Mount unit on support frame as shown in figure 23.

Unit must be level to ensure proper coil drainage,

Leave 5-1/2 inches for service clearance below unit for

condensate trap.

6- Continue with exhaust, condensate and intake line

piping instructions,

Platform Installation of Horizontal Unit Heater

1 - Select location for unit keeping in mind service and

other necessary clearances.

2 - Construct a raised wooden frame and cover frame

with a plywood sheet. Provide service platform and

drain pan for unit. Route auxiliary drain line so that wa-

ter draining from this outlet will be easily noticed by the

homeowner,

3 - Set unit in drain pan as shown in figure 24, Unit must

be level to ensure proper coil drainage, Leave 5-1/2

inches for service clearance below unit for condensate

trap.

4 - Continue with exhaust, condensate and intake piping

installation according to instructions which follow,

*GAS CONNECTOR

INTAKE

*Gas connector may be

PIPE used for Canadian instal-

lation if acceptable by lo-

cal authority havmg juds-

diction.

RAISE

CONDENSATE LINE PLATFORM

FIGURE 24

Return Air -- Horizontal Applications

Return air may be brought in only through the end of a fur-

nace installed in the horizontal position. The furnace is

equipped with a removable bottom panel to facilitate instal-

lation. See figure 9,

This unit is not equipped with a filter or rack, A field-pro-

vided filter is required for the unit to operate properly. Table

3 lists recommended filter sizes.

A filter must be in place whenever the unit is operating.

NOTE - In upflow applications where side return air fil-

ter is installed on same side as the condensate trap, fil-

ter rack must be installed beyond condensate trap to

avoid interference,

TABLE 3

Furnace

Cabinet Size

17-1/2"

21"

24-1/2"

Filter Size

Side Return Bottom Return

16X25X 1(1) 16X25Xl(1)

16X25X 1(1) 20X25Xl(1)

16X25X 1(2) 24X25X 1(1)

Page 16

Loading...

Loading...