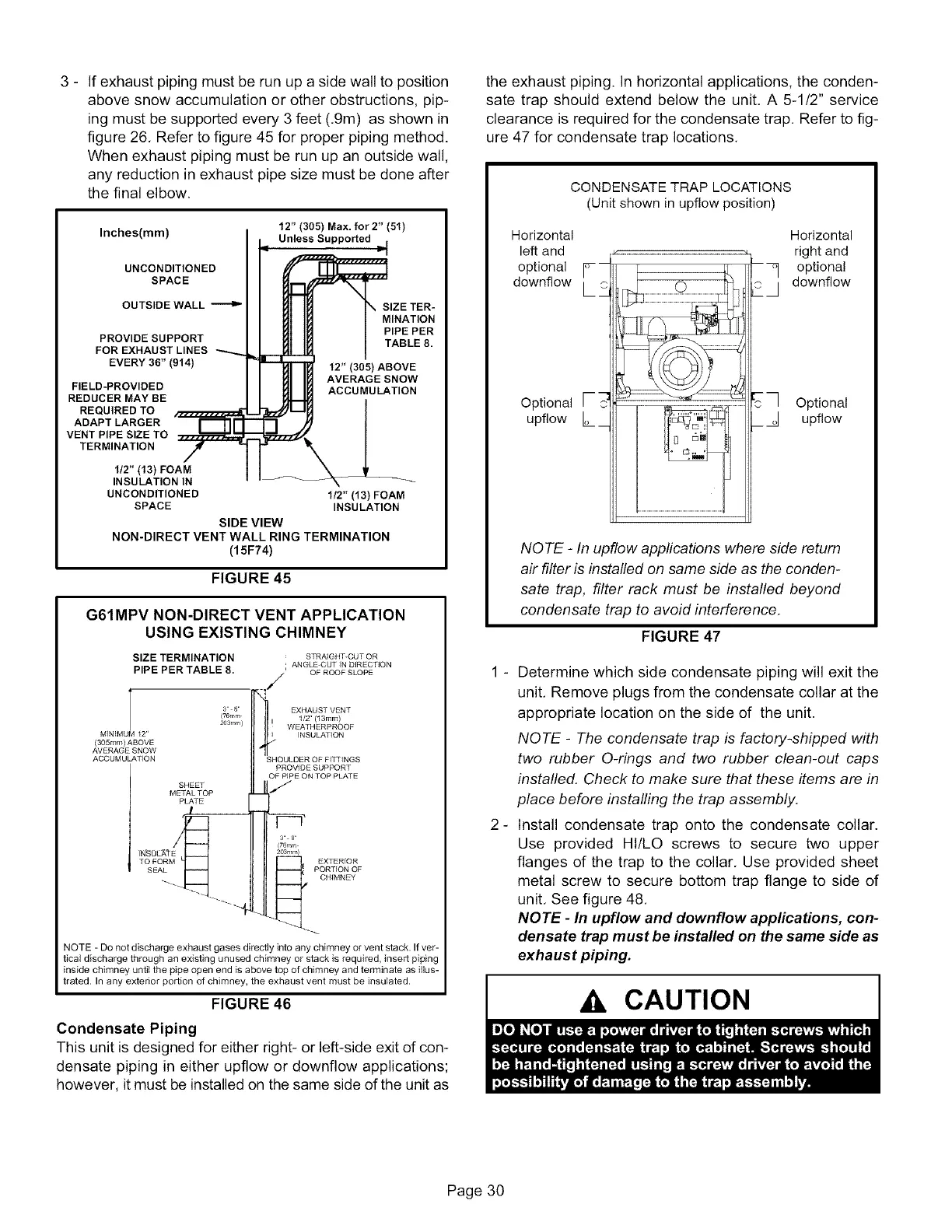

3- Ifexhaustpipingmustberunupasidewalltoposition

abovesnowaccumulationorotherobstructions,pip-

ingmustbesupportedevery3feet(.9m)asshownin

figure26,Refertofigure45forproperpipingmethod.

Whenexhaustpipingmustberunupanoutsidewall,

anyreductioninexhaustpipesizemustbedoneafter

thefinalelbow.

Inches(ram) 12" (305) Max. for 2" (51)

Unless Supported m

UNCONDITIONED

SPACE

OUTSIDE WALL

PROVIDE SUPPORT

FOR EXHAUST LINES

EVERY 30" (914)

FIELD-PROVIDED

REDUCER MAY BE

REQUIRED TO

ADAPT LARGER

VENT PiPE SIZE TO

TERMINATION

SIZE TER-

MINATION

PIPE PER

TABLE 8.

12" (305) ABOVE

AVERAGE SNOW

ACCUMULATION

1/2" (13) FOAM

INSULATION IN

UNCONDITIONED 112" (13) FOAM

SPACE INSULATION

SIDE VIEW

NON-DIRECT VENT WALL RING TERMINATION

(15F74)

FIGURE 45

G61MPV NON-DIRECT VENT APPLICATION

USING EXISTING CHIMNEY

SIZE TERMINATION

PIPE PER TABLE 8.

38

(76m_

203mm)

MINIMU 12"

(_5mm)ABOVE

AVERAGE:NOW

ACCUMULATION

SHEET

METALTOP

PLATE

/_SOLAT_

TOFORM

SEAL

STRAIGHT-CUT OR

' ANGLE CUT iN DIRECTION

OF ROOF SLOPE

EXHAUST VENT

1/2" (13ram)

WEATHERPROOF

INSULATION

SHOULDER OF FI_INGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

3 8

(76ram

203rnm)

EXTERIOR

PORTION OF

CHIMNEY

NOTE - Do not discharge exhaust gases directly into any chimney or vent stack. If ver-

tical discharge through an existing unused chimney or stack is required, insert piping

inside chimney until the pipe open end is above top of chimney and terminate as illus-

trated. In any exterior portion of chimney, the exhaust vent must be insulated.

FIGURE 46

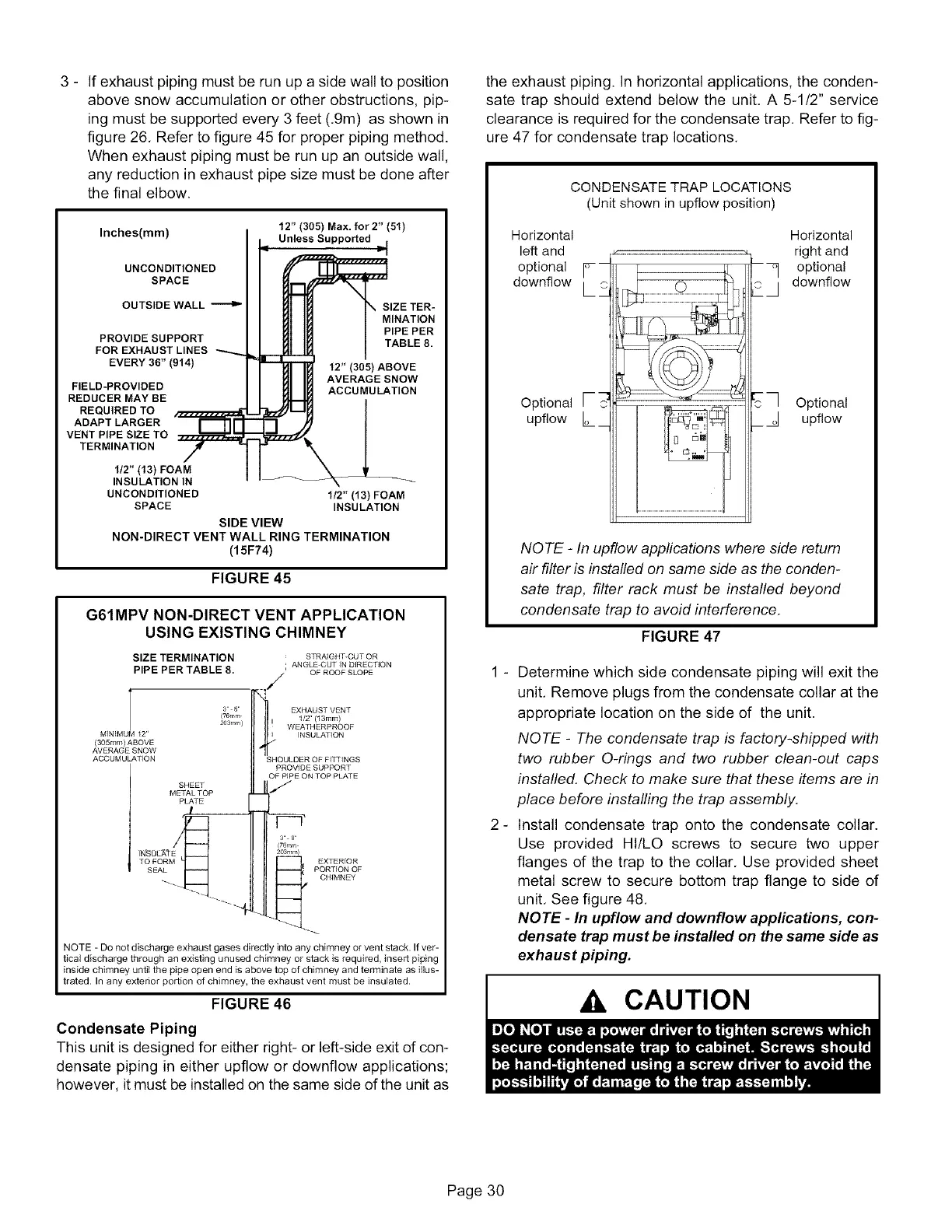

Condensate Piping

This unit is designed for either right- or left-side exit of con-

densate piping in either upflow or downflow applications;

however, it must be installed on the same side of the unit as

the exhaust piping. In horizontal applications, the conden-

sate trap should extend below the unit, A 5-1/2" service

clearance is required for the condensate trap, Refer to fig-

ure 47 for condensate trap locations,

CONDENSATE TRAP LOCATIONS

(Unit shown in upfiow position)

Horizontal Horizontal

left and .............................................................................................right and

downflow°pti°nal_--- _ --_ downflow°pti°nal

L--, :::::::::::::::::::::::::::::::::::::::::::::::.............!J

Optional [--

upflow L_

NOTE - In upflow applications where side return

air filter is installed on same side as the conden-

sate trap, filter rack must be installed beyond

condensate trap to avoid interference.

FIGURE 47

1 - Determine which side condensate piping will exit the

unit, Remove plugs from the condensate collar at the

appropriate location on the side of the unit.

NOTE - The condensate trap is factory-shipped with

two rubber Q-rings and two rubber clean-out caps

installed. Check to make sure that these items are in

place before installing the trap assembly.

2- Install condensate trap onto the condensate collar.

Use provided HI/LO screws to secure two upper

flanges of the trap to the collar, Use provided sheet

metal screw to secure bottom trap flange to side of

unit, See figure 48,

NOTE - In upflow and downflow applications, con-

densate trap must be installed on the same side as

exhaust piping.

CAUTION

Page 30

Loading...

Loading...