Page 52

Use the following steps to correctly size vent pipe diameter.

1 − Determine the vent termination and its corresponding

equivalent feet value according to table 35.

2 − Determine the number of 90° elbows required for both

indoor and outdoor (e.g. snow riser) use. Calculate the

corresponding equivalent feet of vent pipe.

3 − Determine the number of 45° elbows required for both

indoor and outdoor use. Calculate the corresponding

equivalent feet of vent pipe.

4 − Determine the length of straight pipe required.

5 − Add the total equivalent feet calculated in steps 1

through 4 and compare that length to the maximum

values given in table 37 for the proposed vent pipe di-

ameter. If the total equivalent length required exceeds

the maximum equivalent length listed in the appropri-

ate table, evaluate the next larger size pipe.

IMPORTANT

Do not use screens or perforated metal in exhaust

terminations. Doing so will cause freeze−ups and

may block the terminations.

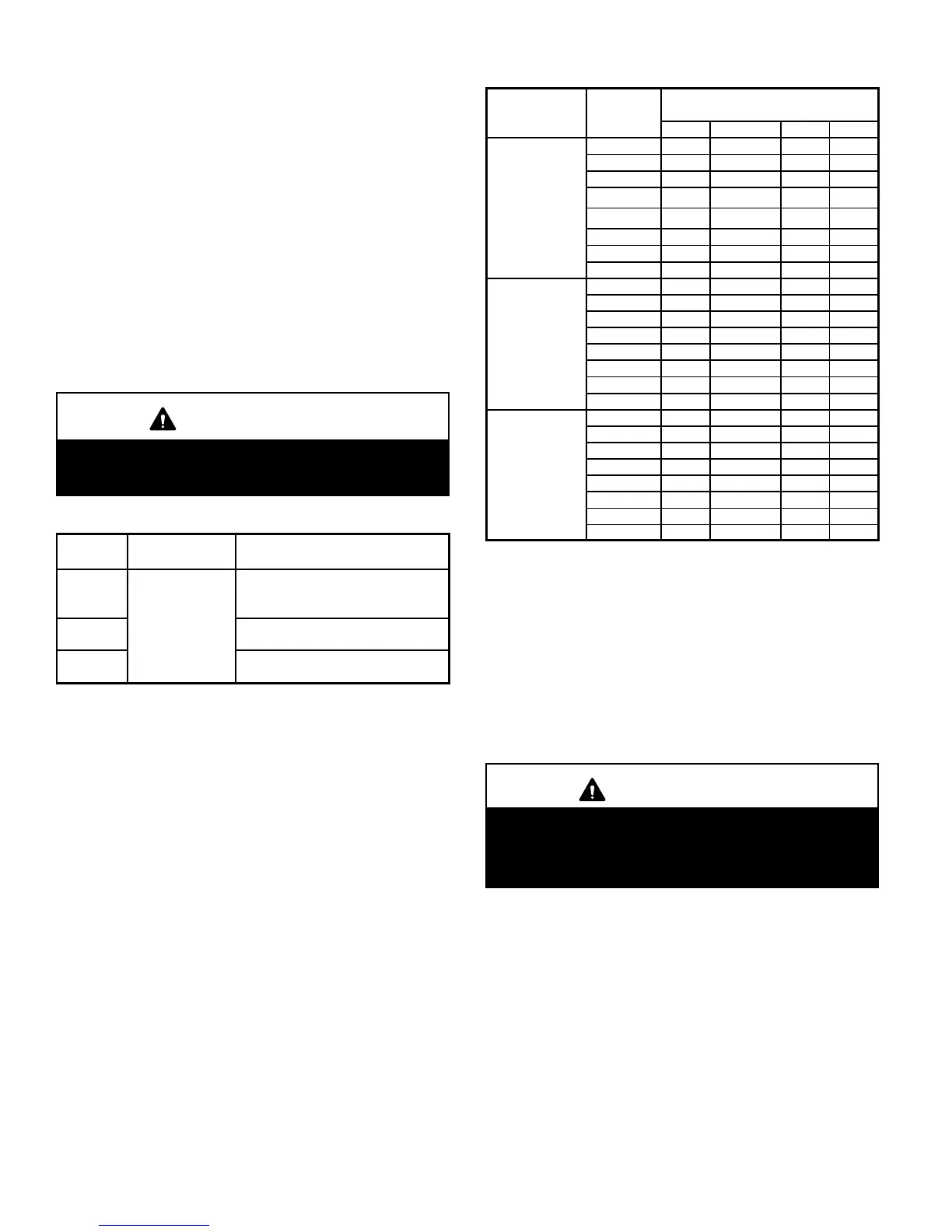

TABLE 36

MINIMUM VENT PIPE LENGTHS

G61MPV

MODEL

MIN. EQUIV.

VENT LENGTH

EXAMPLE

045, 070,

071, 090,

091

15 ft.*

5 ft. plus 2 elbows of 2", 2−1/2", 3"

or 4" diameter pipe

110, 111**

5 ft. plus 2 elbows of 2−1/2" 3" or 4"

diameter pipe

135***

5 ft. plus 2 elbows of 3" or 4"

diameter pipe

*Any approved termination may be added to the minimum equivalent length

listed.

**G61MPV−60C−110 must have 90° street ell (supplied) installed directly into

unit flue collar.

***G61MPV−60D−135 must have 3" to 2" reducing ell (supplied) installed direct-

ly into unit flue collar.

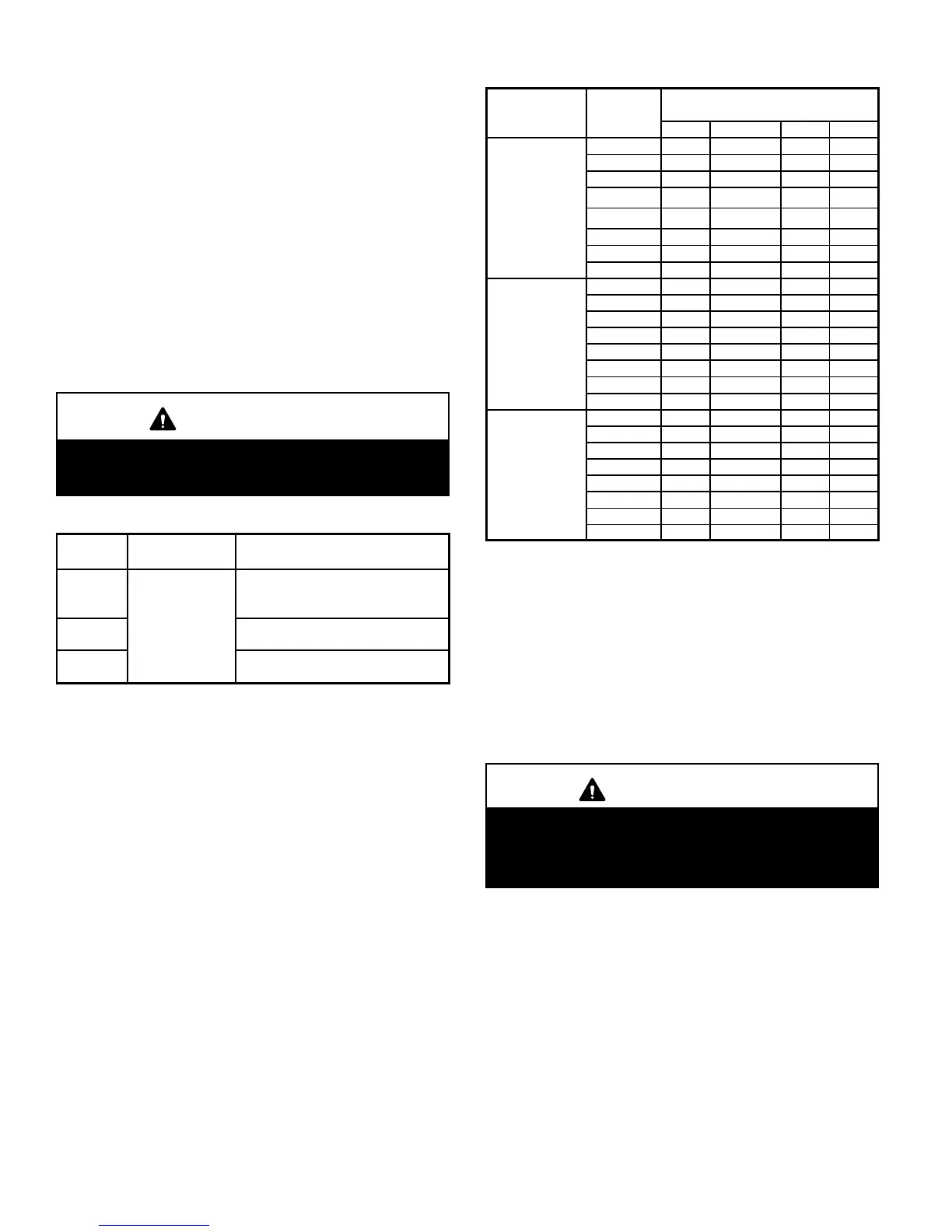

TABLE 37

MAXIMUM VENT PIPE LENGTHS

ALTITUDE

G61MPV

MODEL

MAXIMUM EQUIVALENT VENT

LENGTH FEET

2" dia. 2−1/2" dia. 3" dia. 4" dia.

0 − 4500

(0 − 1371 m)

045 59 65 77 234

070 59 65 78 214

071

†

59 65 78 214

090

26 42 72 204

091

†

26 42 72 204

110* n/a 32 72 179

111

†

n/a 32 72 179

135**

‡

n/a n/a 61 160

4501−7500

(1372−2286 m)

045 59 65 77 234

070 59 65 78 214

0701

†

59 65 78 214

090 26 42 72 204

091

†

26 42 72 204

110* n/a 32 72 179

111

†

n/a 32 72 179

135**

‡

n/a n/a 46 160

7501 − 10000

(2287 − 3048

m)

045 59 65 77 234

070 59 65 78 214

071

†

59 65 78 214

090 26 42 72 204

091

†

26 42 72 204

110* n/a 32 72 179

111

†

n/a 32 72 179

135**

‡

n/a n/a 46 160

n/a −− Not allowed.

*G61MPV−60C−110 must have 90° street ell (supplied) installed directly into

unit flue collar.

**G61MPV−60D−135 must have 3" to 2" reducing ell (supplied) installed directly

into unit flue collar.

†On G61MPV−071, −091 and −111 units, sweep elbows must be used for all

90° elbows in the venting system when 2", 2−1/2" or 3" vent pipe is used.

Sweep elbows are recommended for use in vent systems of other

G61MPV units.

‡

On

G61MPV−60D−135

units,

sweep

elbows

must

be

used

for

all

90°

elbows

in

the

vent

system

when

3"

pipe

is

used.

B−PVC Joint Cementing Procedure

All cementing of joints should be done according to the

specifications outlined in ASTM D 2855.

WARNING

DANGER OF EXPLOSION!

Fumes from PVC glue may ignite during system

check. Allow fumes to dissipate for at least 5 minutes

before placing unit into operation.

1 − Measure and cut vent pipe to desired length.

2 − Debur and chamfer end of pipe, removing any ridges

or rough edges. If end is not chamfered, edge of pipe

may remove cement from fitting socket and result in a

leaking joint.

3 − Clean and dry surfaces to be joined.

4 − Test fit joint and mark depth of fitting on outside of pipe.

5 − Uniformly apply a liberal coat of PVC primer for PVC or

use a clean dry cloth for ABS to clean inside socket

surface of fitting and male end of pipe to depth of fitting

socket.

Loading...

Loading...