Page 30

ÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉ

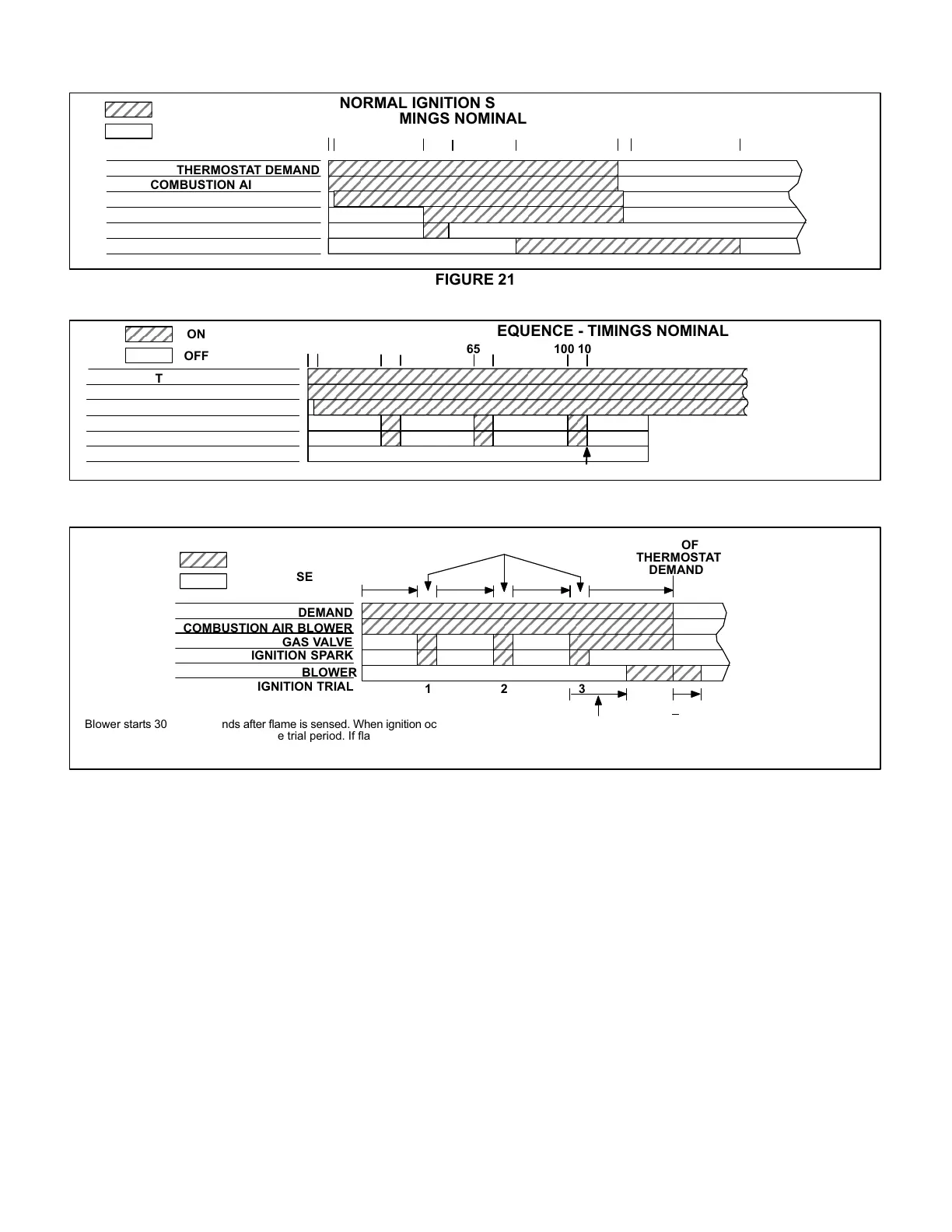

FIGURE 21

NORMAL IGNITION SEQUENCE

TIMINGS NOMINAL

THERMOSTAT DEMAND

COMBUSTION AIR BLOWER

GAS VALVE

IGNITION SPARK

BLOWER

IGNITION TRIAL

SECONDS 0 30 35 0 110

ON / CLOSED

OFF / OPEN

END OF

DEMAND

1

ÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉ

COMBUSTION AIR PROVE SWITCH

5 570

FIGURE 22

RETRIALS - IGNITION ATTEMPT SEQUENCE - TIMINGS NOMINAL

THERMOSTAT DEMAND

COMBUSTION AIR BLOWER

GAS VALVE

IGNITION SPARK

BLOWER

IGNITION TRIAL

SECONDS 0 30 35 70

ON

OFF

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

65 100 105

RESET AT THERMOSTAT

BY BREAKING DEMAND

FENWAL LOCKOUT

COMBUSTION AIR PROVE SWITCH

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

5

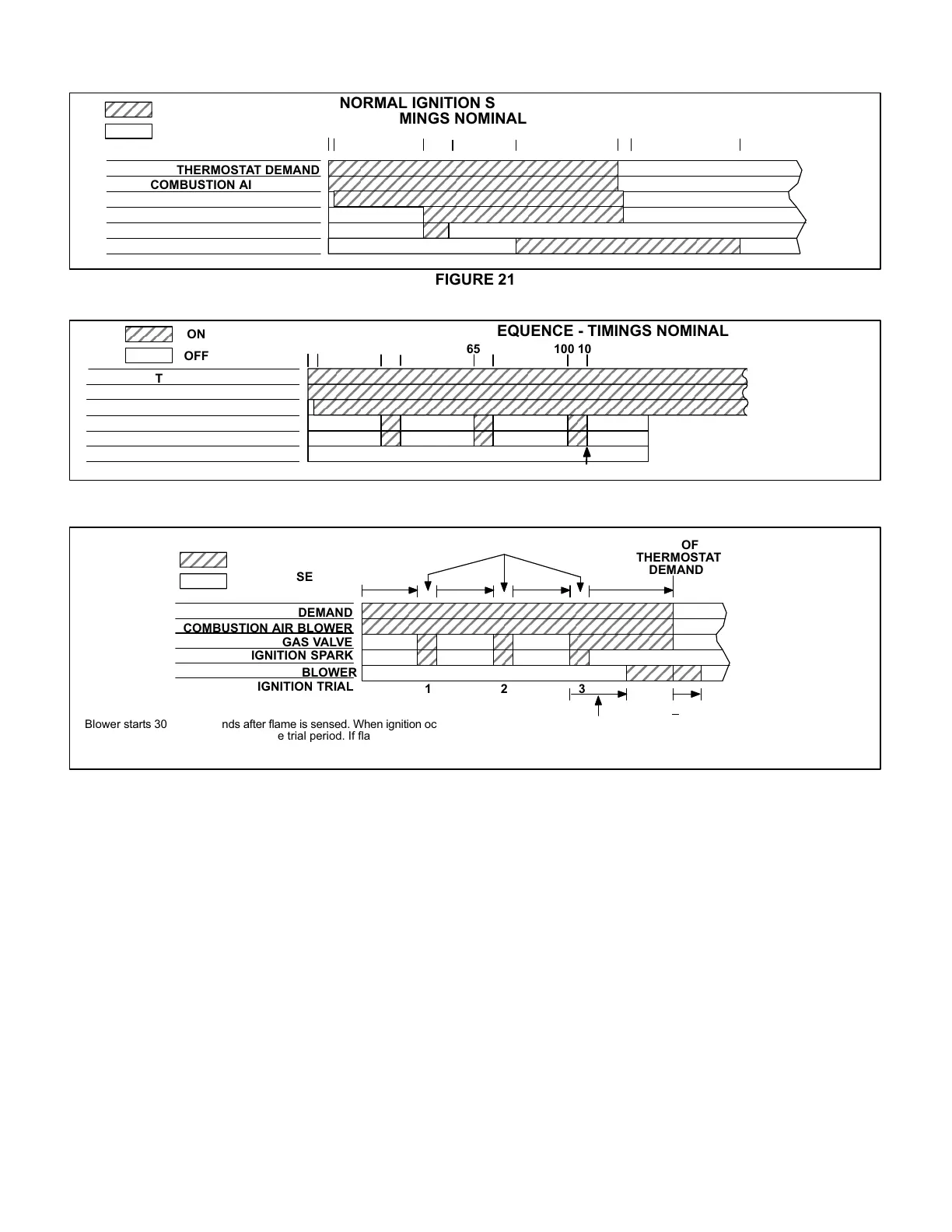

FIGURE 23

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

THERMOSTAT DEMAND

COMBUSTION AIR BLOWER

GAS VALVE

IGNITION SPARK

BLOWER

IGNITION TRIAL

SECONDS 0 30

ON

OFF

FENWAL - IGNITION CONTROL TIMING

30

30

HEATING

CYCLE

6.8 (+3.4, -2.0) SEC.

END OF

THERMOSTAT

DEMAND

12 3

Blower starts 30 to 45 seconds after flame is sensed. When ignition occurs on any trial, heating cycle begins. Ignition spark remains on for a total of 6.8 +3.4,

-2.0 seconds from the beginning of the trial period. If flame sensor detects loss of flame during heating cycle, gas valve remains open and ignition spark

begins for one second. If flame is detected before the end of one second, spark stops and the heating cycle continues. If flame is not detected during the

one second ignition retrial, the control cycles through the complete ignition sequence before locking out.

110+20 sec.

12-Heat Exchanger (Figure 15)

The GCS16 uses aluminized steel inshot burners with

matching tubular aluminized steel heat exchangers. Mod

els may be equipped with single or dual heat exchangers

depending on heating capacity. The second heat ex

changer in dual heat exchanger models is identical to the

first. Each heat exchanger uses multipletube/burner as

semblies controlled by a single two-stage gas valve. Each

burner uses a burner venturi to mix gas and air for proper

combustion. Combustion takes place at each tube en

trance. As hot combustion gases are drawn upward

through each tube by the combustion air blower, exhaust

gases are drawn out the top and fresh air/gas mixture is

drawn in at the bottom. Heat is transferred to the air stream

from all surfaces of the heat exchange tubes. The supply

air blower, controlled by the ignition control or the control

system (depending on which control system is installed),

forces air across all surfaces of the tubes to extract the

heat of combustion. The shape of the tubes and a deflector

ensure maximum heat exchange.

The gas valve accomplishes staging by allowing more or

less gas to the burners as called for by heating demand.

Single heat exchanger models accomplish staging by

cycling the second stage operator of the gas valve. When

thermostat demand calls for more heat, the second opera

tor of the gas valve opens to allow more gas to the burners.

Dual heat exchanger models are factory equipped to pro

vide two stages of heat in four increments. The first and

second stage operators of the first stage gas valve are

connected in parallel. The first stage operator of the gas

valve opens quickly but the second stage operator opens

Loading...

Loading...