Page 31

slowly. On a heating call, the first stage operator opens im

mediately to begin first stage heating operation (first incre

ment). At the same time, the second stage operator begins

opening slowly (second increment). The second stage op

erator reaches full open after approximately 90 seconds.

The second heat exchanger is identical to the first heat ex

changer. The second heat exchanger operates in re

sponse to second stage (W2) demand. The first stage op

erator of the second gas valve (GV3W1) provides second

stage (third increment) heat and the second operator

opens slowly (fourth increment).

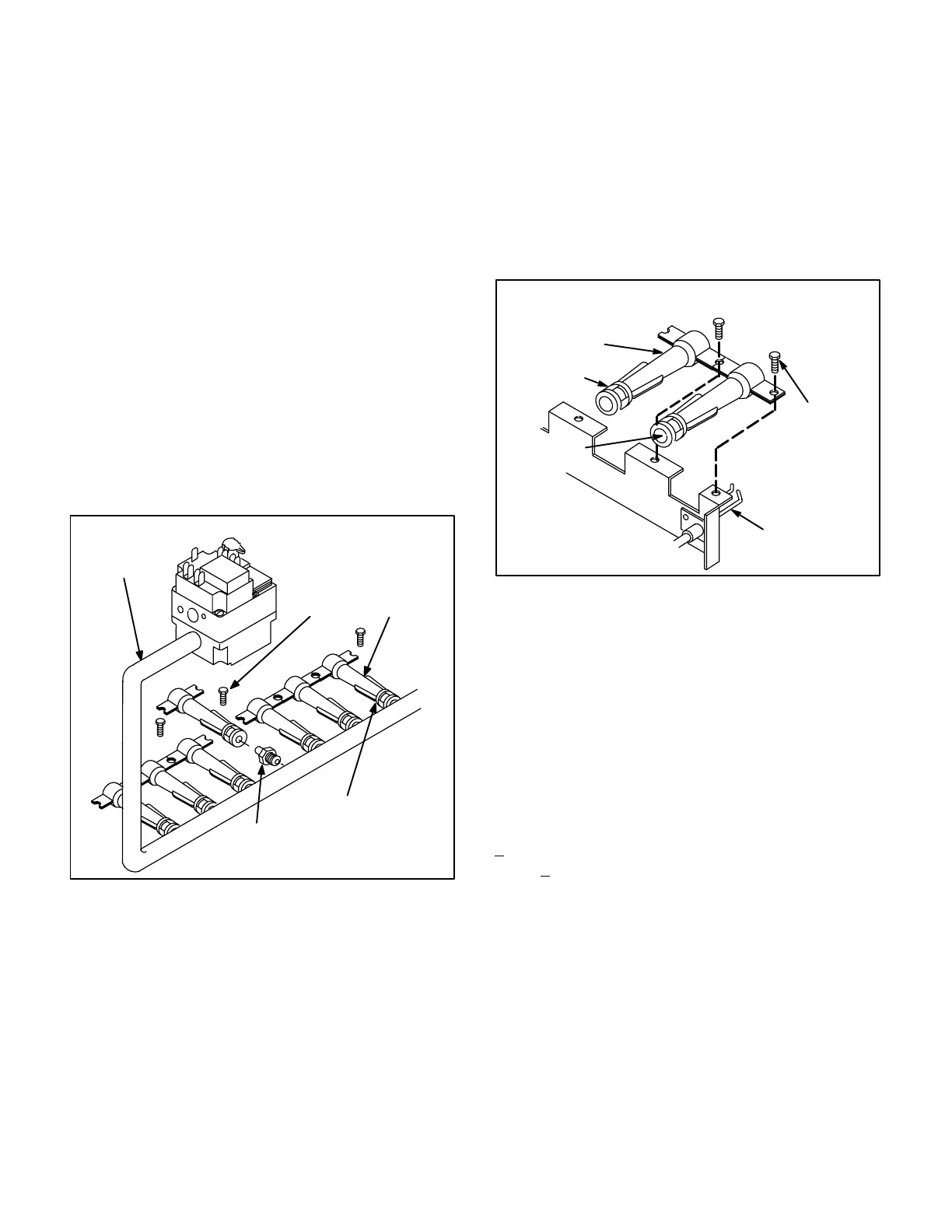

13-Burner Assembly (Figure 24)

The burners are controlled by the spark electrode, flame

sensing electrode, gas valve GV1 and combustion air blower.

The spark electrode, flame sensing electrode and gas valve

are directly controlled by the ignition control. The ignition con

trol is controlled by the combustion air blower. The combus

tion air blower is controlled by heating demand from the ther

mostat or control system.

FIGURE 24

TYPICAL GAS MANIFOLD ASSEMBLY

GAS VALVE GV1

BURNERS

AIR SLOTS

BURNER

RETAINER

SCREW

MANIFOLD

ORIFICE

GAS VALVE POSITION

SLIGHTLY DIFFERENT

IN DUAL HEAT EX

CHANGER MODELS

a-Burners

All units use inshot burners (see figures 24 and 25 ).

Burners are factory set and do not require adjustment.

Burner air shutters are designed to be fully open only.

A peep hole with cover is furnished in the heating ac

cess panel for flame viewing. Always operate the unit

with the access panel in place. Burners can be re

moved individually for service. Burner maintenance

and service is detailed in the SERVICE CHECKS and

MAINTENANCE sections of this manual.

b-Orifice

Each burner uses an orifice which is precisely matched

to the burner input. The orifice is threaded into the burn

er manifold. The burner is supported by the orifice and

will easily slide off for service.

Each orifice and burner are sized specifically to the

unit. Refer to Lennox Repair Parts Listing for correct

sizing information.

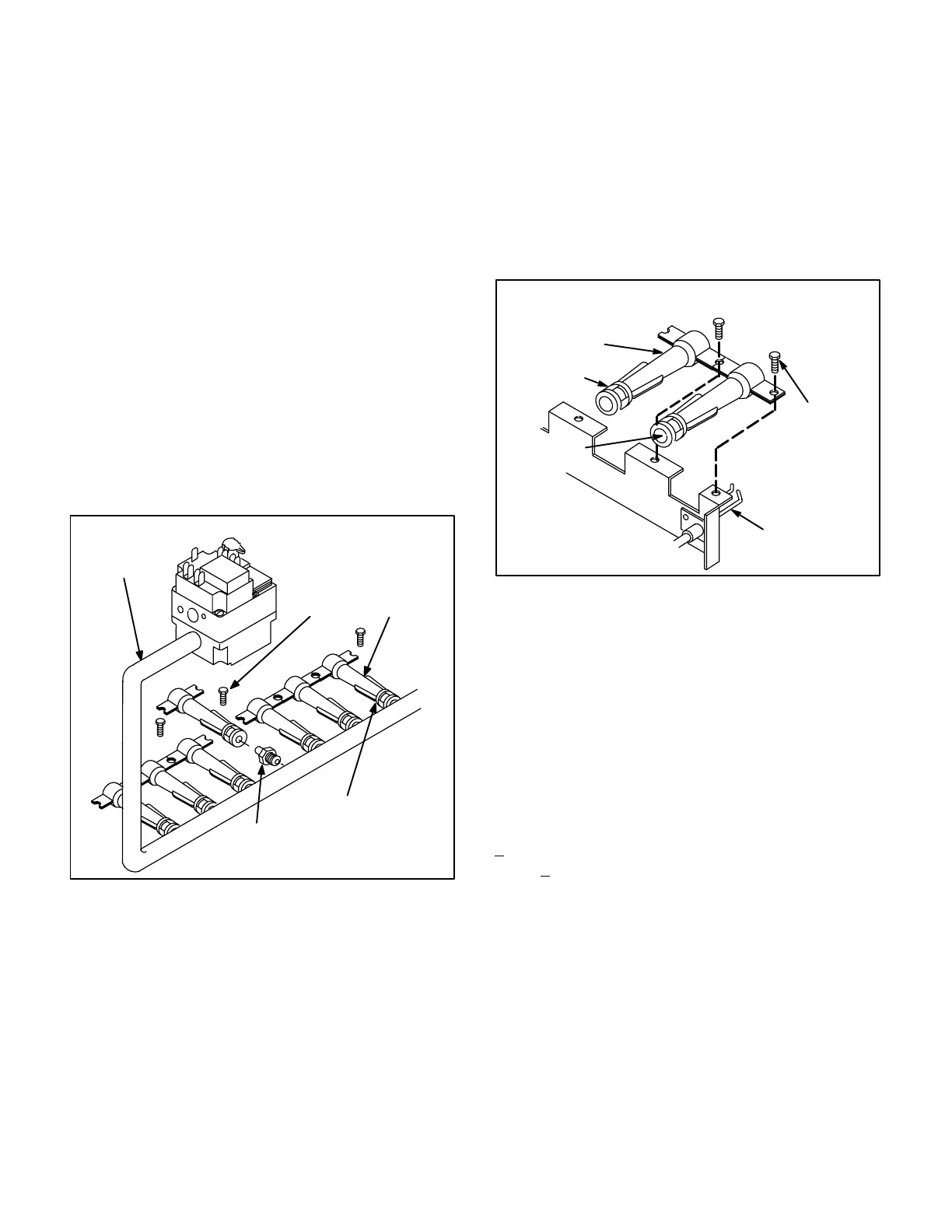

TYPICAL BURNER AND ELEC

TRODE ASSEMBLY

BURNER

AIR SLOTS

ORIFICE

OPENING

ELECTRODE/

FLAME SENSOR

ASSEMBLY

SCREWS

FIGURE 25

D-Primary High Temperature Limit S10

S10 is the primary high temperature limit. It is located in

the heating compartment and is mounted to the lower por

tion of the panel dividing the heating compartment from

the blower compartment.

Primary limit S10 is wired in series with the ignition control.

Its N.C. contacts open to de-energize the ignition control

when excessive temperature is reached in the blower

compartment. The limit is a SPDT auto-reset switch. The

limit is factory preset to open its N.C. terminals at 165F

+6F on a temperature rise and automatically reset at

125F +7F on a temperature fall. The ignition circuit is im

mediately de-energized when terminals 1-3 open and

relay K20 is energized when terminals 1-2 close. This is a

primary safety shut-down function of the unit.

In dual heat exchanger models, both heat exchangers are

disabled when S10 opens. In fifteen ton and larger units,

the combustion air blower(s) continue to operate when

S10 opens.

E-Secondary High Temperature Limit S21

S21 is the secondary high temperature limit. It is also lo

cated in the heating compartment and is mounted to the

upper portion of the panel dividing the heating compart

ment from the blower compartment.

Loading...

Loading...