Page 22

System Operation

UNIT COMPONENTS

IMPORTANT

Some scroll compressors have an internal vacuum

protector that will unload scrolls when suction pressure

goes below 20 psig. A hissing sound will be heard when

the compressor is running unloaded. Protector will

reset when low pressure in system rises above 40 psig.

DO NOT REPLACE COMPRESSOR.

The outdoor unit and indoor blower cycle on demand from

the room thermostat. If the thermostat blower switch is in

the ON position, the indoor blower operates continuously.

Bi-Flow Liquid line Filter Drier

The unit is equipped with a large-capacity bi-ow lter dri-

er which keeps the system clean and dry. If replacement is

necessary, order another of the same design and capac-

ity. The replacement lter drier must be suitable for use

with HFC-410A refrigerant.

High Pressure Switch (S4)

This unit is equipped with a high pressure switch which is

located on the liquid line. The SPST, normally closed pres-

sure switch opens when liquid line pressure rises above

the factory setting of 590 + 15 psig and automatically re-

sets at 418 + 15 psig.

If the high pressure switch opens 5 times during a single

thermostat demand, the defrost control will lock out the

compressor.

Low Pressure Switch (S87)

This unit is equipped with a low pressure switch which is

located on the suction line. The SPST, normally closed

pressure switch opens when the suction pressure drops

below the factory setting of 25 PSIG +/- 5 PSIG and auto-

matically resets at 40 PSIG +/- 5 PSIG. If the low pressure

switch opens 5 times during a single thermostat demand,

the defrost control will lock out the compressor. The de-

frost control has an on-board thermistor and will ignore the

pressure switch when the outdoor temperature is below

approximately 15 degrees F.

Resetting Defrost Control High and Low Pressure

Switch Lockout

The defrost control will lock out the compressor if the

high or low pressure switch opens 5 times during a single

thermostat demand. To reset a 5-strike pressure switch

lockout, cycle 24V control power to the defrost control or

place the defrost control in the “TEST” mode by shorting

the “TEST” pins for 2 seconds.

Defrost Thermostat (S6)

The defrost thermostat is located on the liquid line be-

tween the check/expansion valve and the distributor.

When defrost thermostat senses 42°F (5.5°C) or cooler,

the thermostat contacts close and send a signal to the

defrost control to start the defrost timing. It also terminates

defrost when the liquid line warms up to 70°F (21°C).

Crankcase Heater (HR1) and Thermostat Switch (S40)

Certain models are equipped with a belly band type crank-

case heater. HR1 prevents liquid from accumulating in the

compressor. The HR1 is controlled by a single pole, single

throw thermostat switch (S40) located on the liquid line.

On all units, the heater is on when there is no compressor

operation.

Thermal Protection Switch (S173) – Compressor

Mounted

Some ML14XP1 units are equipped with a compressor

mounted normally closed temperature switch that pre-

vents compressor damage due to overheating caused by

internal friction. The switch is located on top of the com-

pressor casing (see gure 1).

This switch senses the compressor casing temperature

and opens at 239-257°F (115°C-125°C) to shut o com-

pressor operation. The auto-reset switch closes when

the compressor casing temperature falls to 151-187°F

(66°C-86°C), and the compressor is re-energized. This

single-pole, single-throw (SPST) bi-metallic switch is

wired in series with the 24V Y input signal to control com-

pressor operation.

System Conguration

The defrost system includes a defrost thermostat (S6) and

a defrost control (CMC1).

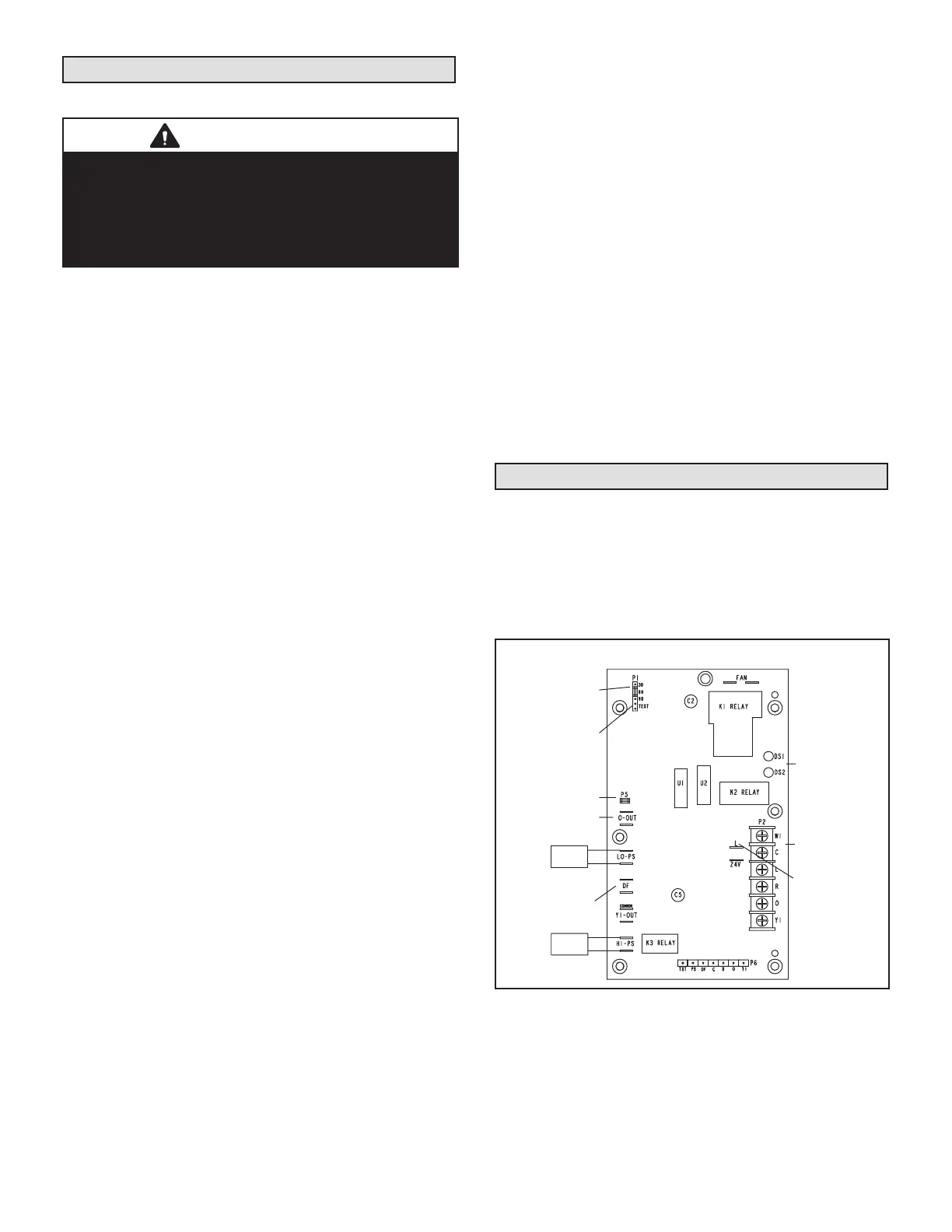

DEFROST CONTROL (CMC1)

This defrost control includes the combined functions of a

time/temperature defrost control, defrost relay, time delay,

diagnostic LEDs and a terminal strip for eld wiring con-

nections.

24V TERMINAL

STRIP

CONNECTIONS

DIAGNOSTIC

LEDS

HIGH PRESSURE

TEST

PINS

DEFROST TIMING

PINS (P1)

REVERSING

VALVE

DEFROST

THERMOSTAT (S6)

LOW PRESSURE

SWITCH

COMPRESSOR

DELAY PINS

S4

S87

SERVICE LIGHT

CONNECTIONS

FIGURE 14

The defrost control provides automatic switching from nor-

mal heating operation to defrost mode and back. When

the defrost thermostat is closed, the control accumulates

compressor run time at 30-, 60- or 90- minute eld-adjust-

able intervals.

When the selected compressor run time interval is

reached, the defrost relay is energized and defrost begins.

Loading...

Loading...