Page 17

Approach Method and

Normal Operating Pressures

TXV Systems – Outdoor Temp. >

65F (18C)

The following procedure is intended as a general guide and

is for use on expansion valve systems only. For best results,

indoor temperature should be 70°F (21°C) to 80°F (26°C).

Monitor system pressures while charging.

1 − Record outdoor ambient temperature using a digital

thermometer.

2 − Attach high pressure gauge set and operate unit for

several minutes to allow system pressures to stabilize.

3 − Compare stabilized pressures with those provided in

table 8, Normal Operating Pressures." Minor varia-

tions in these pressures may be expected due to differ-

ences in installations. Significant differences could

mean that the system is not properly charged or that a

problem exists with some component in the system.

Pressures higher than those listed indicate that the

system is overcharged. Pressures lower than those

listed indicate that the system is undercharged. Verify

adjusted charge using the approach method.

Approach Method

4 − Use the same digital thermometer you used to check

the outdoor ambient temperature to check the liquid

line temperature.

5 − The difference between the ambient and liquid temper-

atures should match values given in table 7. If the val-

ues don’t agree with the those in table 7, add refriger-

ant to lower the approach temperature, or recover re-

frigerant from the system to increase the approach

temperature.

Be aware of the R410A refrigerant cylinder. It will be

rose−colored. Refrigerant should be added through the

vapor valve in the liquid state. Some R410A cylinders

are equipped with a dip tube which allows you to

draw liquid refrigerant from the bottom of the cylin-

der without turning the cylinder upside−down. The

cylinder will be marked if it is equipped with a dip

tube.

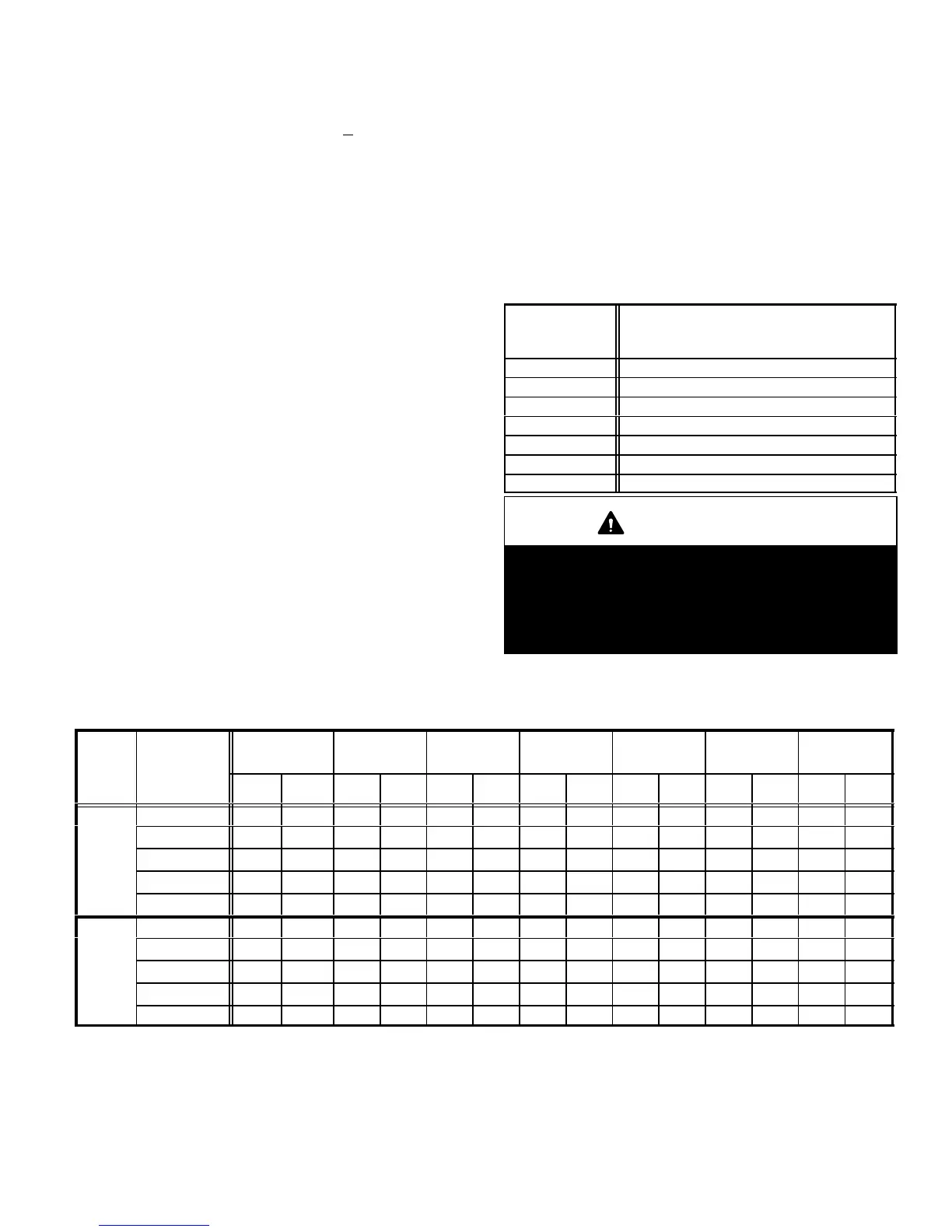

Table 7

HSXA12 Approach Values

Model No.

Approach Temperature

Liquid Line −

Outdoor Ambient °F (°C)

−018 10 (5.6)

−024 12 (6.7)

−030 13 (7.2)

−036 12 (6.7)

−042 11 (6.1)

−048 13 (7.2)

−060 14 (7.8)

IMPORTANT

Use table 8 to perform maintenance checks. Table 8

is not a procedure for charging the system. Minor

variations in these pressures may be due to differ-

ences in installations. Significant deviations could

mean that the system is not properly charged or that

a problem exists with some component in the system.

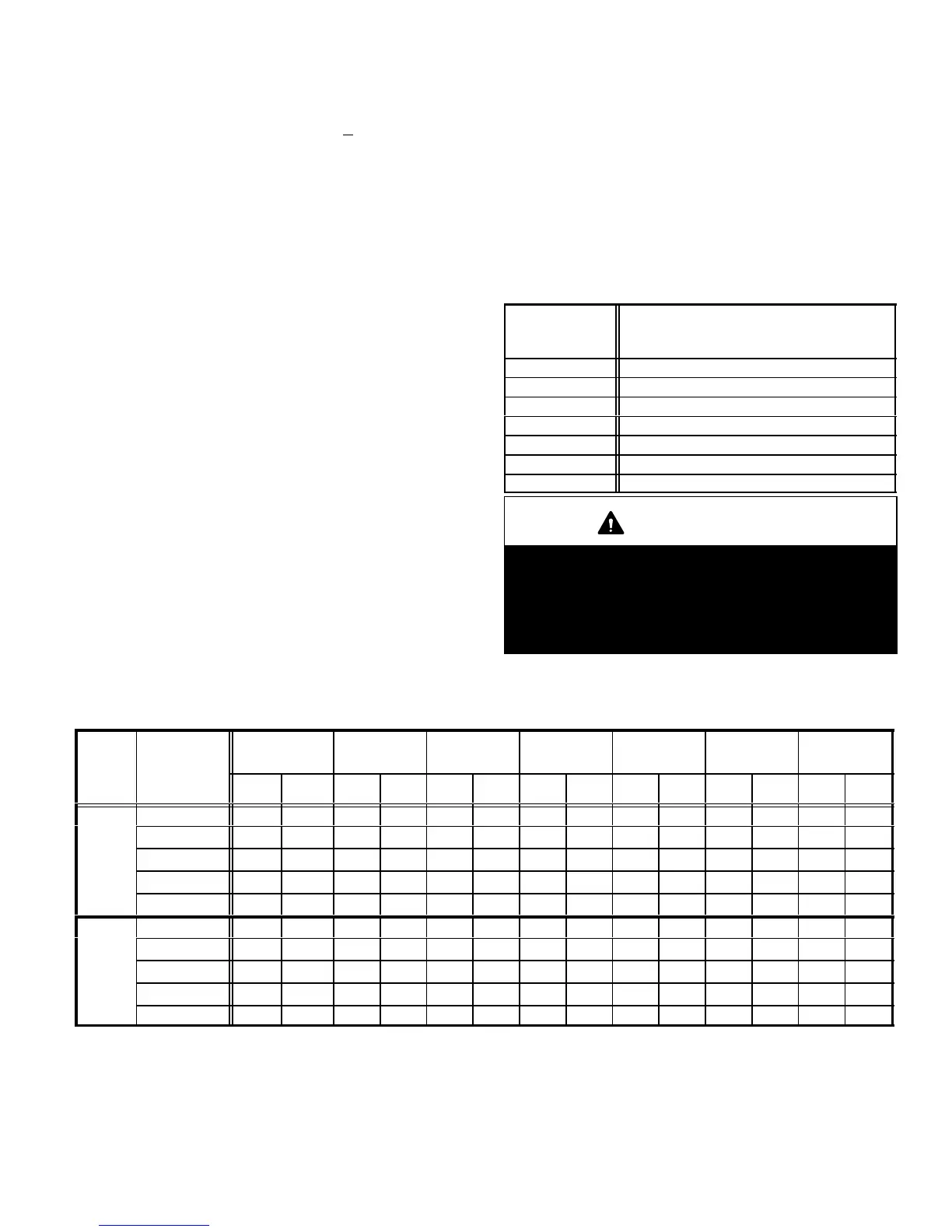

Table 8

Normal Operating Pressures In psig (liquid +/− 10 and vapor +/− 5 PSIG)*

Mode

Out. Coil

Entering Air

−018 −024 −030 −036 −042 −048 −060

Temp.

°F (°C)

LIQ SUC LIQ SUC LIQ SUC LIQ SUC LIQ SUC LIQ SUC LIQ SUC

65 (18.3) 238 123 261 131 261 128 268 130 254 121 270 124 280 121

75 (23.9) 275 131 300 135 300 133 308 134 296 128 311 130 332 126

fixed

85 (29.4) 317 136 343 139 343 138 351 138 340 133 356 134 379 130

orifice

95 (35.0) 362 141 391 143 387 141 398 142 389 138 404 139 427 135

105 (40.6) 410 144 441 147 434 145 447 146 440 142 456 143 479 140

65 (18.3) 234 133 256 134 256 137 264 135 256 124 269 131 262 121

75 (23.9) 270 135 298 137 296 139 305 138 296 127 312 133 304 127

TXV

85 (29.4) 312 137 344 140 339 141 349 139 341 133 357 135 349 132

95 (35.0) 361 138 394 142 384 144 396 140 389 136 406 137 397 136

105 (40.6) 409 141 448 143 432 146 446 143 440 140 460 140 449 140

*These are typical pressures only. Indoor indoor match up, indoor air quality, and indoor load will cause the pressures

to vary.

Loading...

Loading...