Page 44

LGH/LCH036, 048, 060, 072

WARNING

Units are shipped from the factory with temporary

filters. Replace filters before building is occupied.

Damage to unit could result if filters are not re

placed with approved filters. Refer to appropriate

codes.

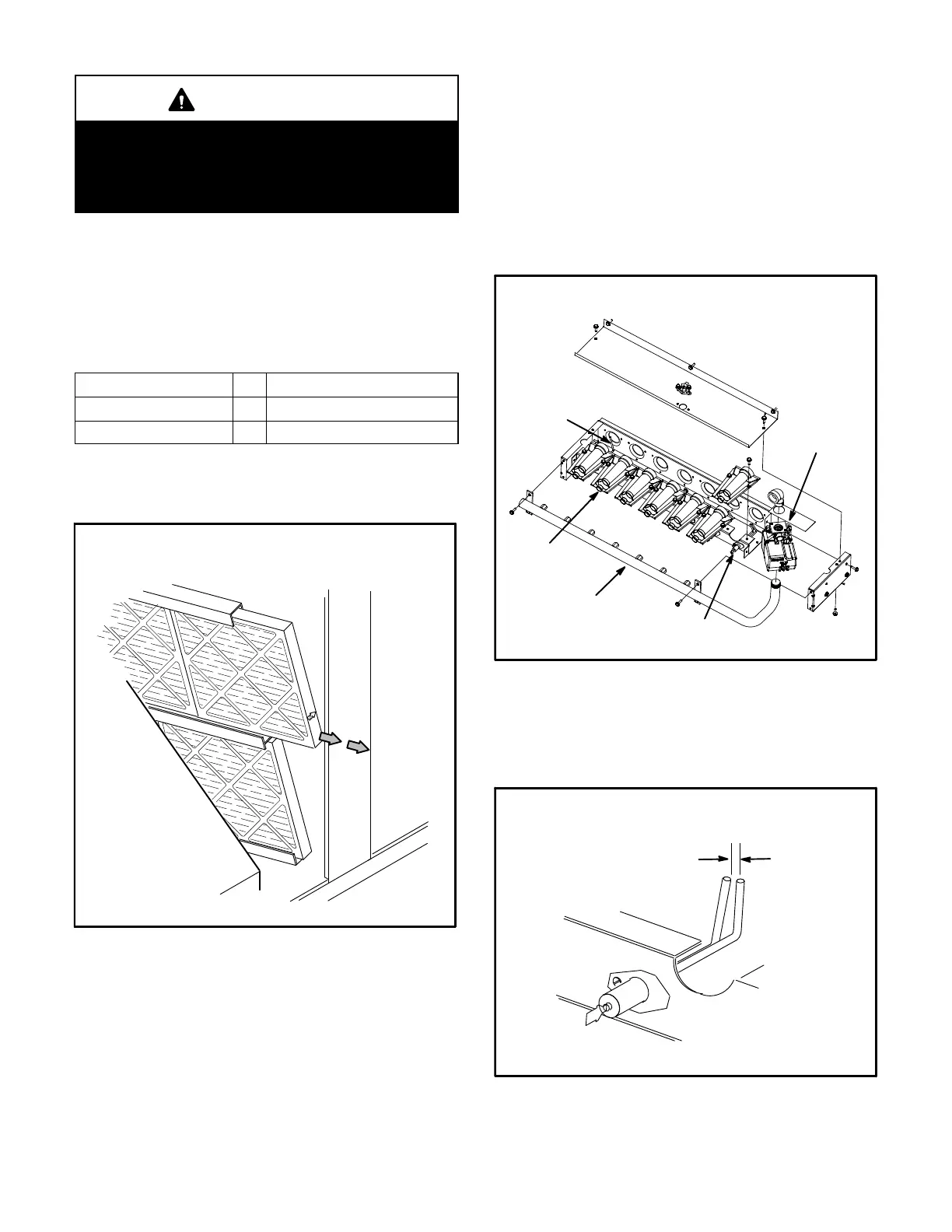

Approved filters should be checked monthly and

replaced when necessary. Take note of air flow direction

marking on filter frame when reinstalling filters. See

figure 31.

TABLE 32

UNIT FILTERS

Unit Qty Filter Size - inches (mm)

036, 048 4 16 X 20 X 2 (406 X 508 X 51)

060, 072 4 20 X 20 X 2 (508 X 508 X 51)

NOTE-Filters must be U.L.C. certified or equivalent for

use in Canada.

FIGURE 31

REMOVE FILTERS

PULL TO

REMOVE

FILTERS

B-Lubrication

All motors are lubricated at the factory. No further

lubrication is required.

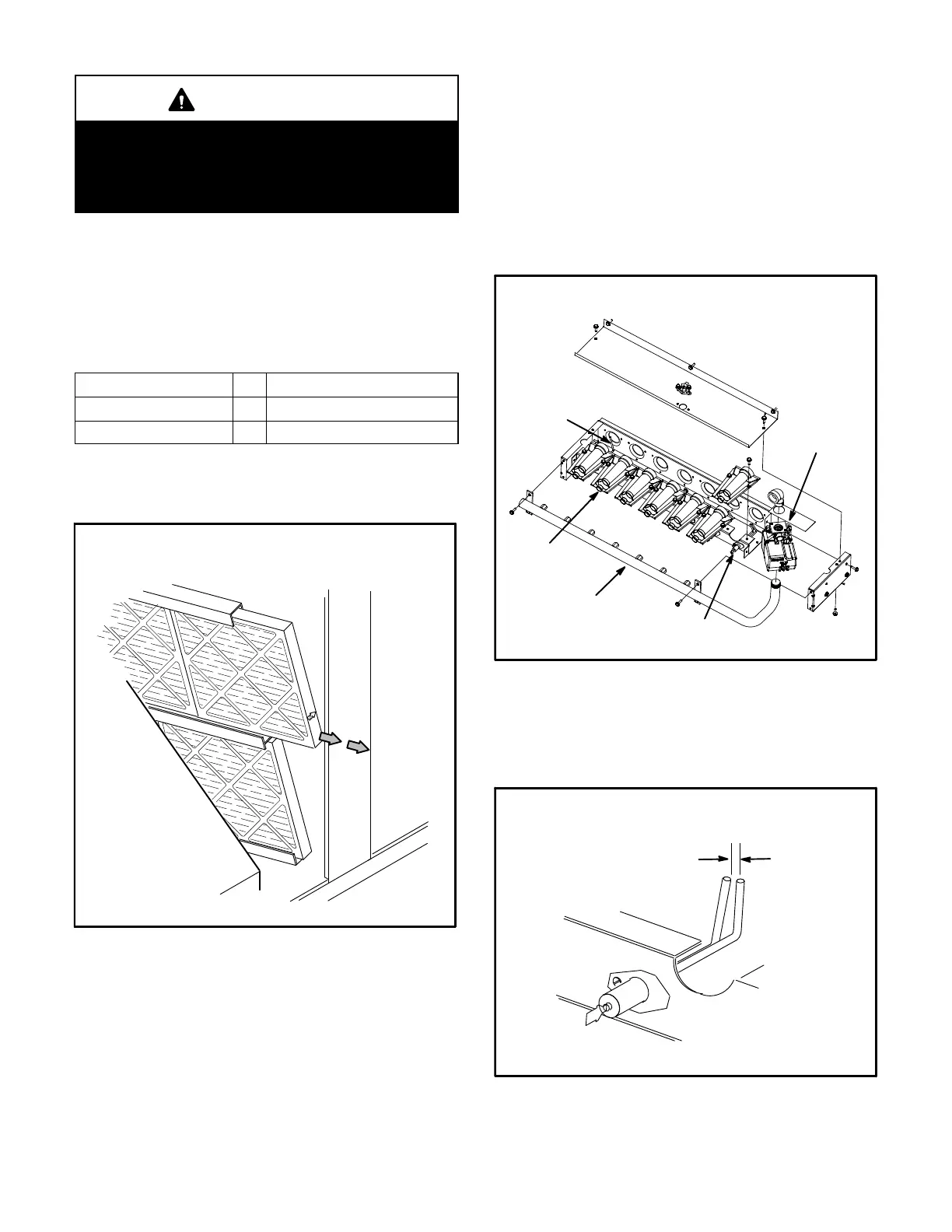

C-Burners (Gas Units)

Periodically examine burner flames for proper

appearance during the heating season. Before each

heating season examine the burners for any deposits or

blockage which may have occurred.

Clean burners as follows:

1- Turn off both electrical power and gas supply to unit.

2- Remove burner compartment access panel.

3- Remove top burner box panel.

4- Remove two screws securing burners to burner

support and lift the burners from the orifices. See

figure 32. Clean as necessary.

FIGURE 32

BURNER BOX ASSEMBLY

GAS VALVE

GAS

MANIFOLD

FLAME

SENSOR

BURNERS

IGNITOR

5- Locate the ignitor under the right burner. Check

ignitor spark gap with appropriately sized twist drills

or feeler gauges. See figure 33.

FIGURE 33

IGNITOR

SPARK GAP

SHOULD BE 1/8”

(3mm)

6- Replace burners and screws securing burner. See

figure 34.

Loading...

Loading...