Do you have a question about the Lennox LGH 036 and is the answer not in the manual?

Specifies the model series for the installation instructions.

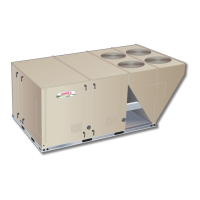

Provides unit dimensions and illustrates component layout for LGH/LCH036-072 models.

Illustrates the major components and their arrangement within the unit.

Details the contents of the unit packaging and inspection procedures.

Provides general information, safety precautions, and unit specifications.

Outlines necessary clearances and support requirements for installation.

Describes methods and requirements for securely supporting the unit during installation.

Provides guidance on connecting ductwork according to applicable codes and insulation requirements.

Details procedures and safety precautions for lifting and rigging the unit.

Explains how to configure the unit for horizontal airflow discharge.

Provides instructions for connecting and managing condensate drains.

Details the steps for modifying the unit to drain condensate from the rear.

Details the steps for modifying the unit to drain condensate from the bottom.

Provides instructions and safety precautions for connecting the gas supply to the unit.

Outlines procedures for safely testing gas piping connections for leaks.

Explains adjustments required for units installed at high altitudes.

Details the procedures for making electrical connections to the unit.

Covers wiring for thermostats, zone sensors, and other control components.

Describes how to connect and configure the unit for thermostat control.

Explains how to connect and configure the unit for zone sensor control.

Provides specific wiring instructions for units with hot gas reheat functionality.

Details how to operate and adjust the unit's blower for optimal performance.

Explains how to adjust airflow (CFM) for units with direct drive blowers.

Describes how to adjust airflow (CFM) for units with belt drive blowers via pulley adjustment.

Provides guidance on proper pulley alignment and belt tension for belt drive blowers.

Details how to adjust belt tension on units with an optional belt tensioner.

Explains how to check and set the proper belt tension for optimal performance.

Refers to specific pages for determining BHP and RPM for field-furnished blower drives.

Presents performance data for direct drive blowers in downflow applications.

Presents performance data for direct drive blowers in downflow applications.

Presents performance data for direct drive blowers in horizontal applications.

Presents performance data for direct drive blowers in downflow applications.

Presents performance data for direct drive blowers in downflow applications.

Presents performance data for direct drive blowers in horizontal applications.

Presents performance data for belt drive blowers in downflow applications.

Presents performance data for belt drive blowers in downflow applications.

Presents performance data for belt drive blowers in horizontal applications.

Presents performance data for belt drive blowers in downflow applications.

Presents performance data for belt drive blowers in downflow applications.

Presents performance data for belt drive blowers in horizontal applications.

Presents performance data for belt drive blowers in downflow applications.

Presents performance data for belt drive blowers in downflow applications.

Presents performance data for belt drive blowers in horizontal applications.

Presents performance data for belt drive blowers in downflow applications.

Presents performance data for belt drive blowers in downflow applications.

Provides specifications for belt drive kits, including motor HP and RPM ranges.

Provides air resistance data for factory options and field accessories.

Covers the procedures for starting up the cooling system, including compressor and blower operation.

Provides general instructions for initiating cooling operation and checking system status.

Details voltage phasing requirements for three-phase scroll compressors for correct rotation.

Describes procedures for checking and adjusting refrigerant charge for all-aluminum coils.

Continues the approach method for verifying charge, focusing on fin/tube coils.

Presents a graphical representation of charging parameters for LGH/LCH036S units.

Presents a graphical representation of charging parameters for LGH/LCH036H units.

Provides charging curves for LGH/LCH048S units based on outdoor temperature and suction pressure.

Provides charging curves for LGH/LCH048H units based on outdoor temperature and suction pressure.

Presents charging parameters for LGH/LCH060S units, showing relationships between pressures and temperatures.

Presents charging parameters for LGH/LCH060H units, showing relationships between pressures and temperatures.

Provides charging curves for LGH/LCH072H units, correlating suction pressure and liquid temperature.

Details the process for checking and adjusting refrigerant charge for fin/tube coils.

Continues the approach method for verifying charge, focusing on fin/tube coils.

Describes various compressor protection controls and their functions.

Provides step-by-step instructions for safely starting up the gas heating system.

Details how gas heating systems operate and provides adjustment guidance.

Guides the installation and setup of the Ventilation Control Board (VCB).

Instructs how to enter design-specified airflow values into the Unit Controller.

Provides the menu path to enter supply air CFM values into the Unit Controller.

Explains how to input outdoor airflow CFM design specifications into the Unit Controller.

Describes how the unit operates based on specified CFM and thermostat demand.

Explains the function and setup of the SCR Electric Heat Controller for LCH units.

Details the startup and operational procedures for hot gas reheat units, including refrigerant routing.

Provides a procedure to test reheat operation and verify component de-energization.

Describes the default behavior of the unit during reheat mode, including free cooling lockout.

Recommends annual servicing by a qualified technician to maintain efficiency and longevity.

Instructs on replacing temporary filters with approved ones before building occupation.

States that all motors are lubricated at the factory and require no further lubrication.

Provides instructions for cleaning gas burners periodically for proper appearance and to remove deposits.

Details how to check and clean the combustion air inducer for proper operation.

Provides instructions for cleaning the flue box cover and heat exchanger tubes when necessary.

Describes the process for inspecting and cleaning the evaporator coil at the beginning of each cooling season.

Provides annual cleaning and monthly inspection procedures for condenser coils (all-aluminum and fin/tube).

Describes annual inspection and cleaning of the supply air blower wheel for accumulated dirt.

Contains critical safety warnings and precautions for installation and operation.

Provides instructions for safely placing the unit into operation, including pre-lighting checks.

Details the operation of the gas valve, including settings and safety procedures.

Provides instructions on how to safely turn off the gas supply to the unit.

Describes the expected burner flame appearance and inspection procedures.

Outlines annual inspection requirements for flue passages and vents to ensure proper operation.

Recommends annual servicing by a qualified technician to maintain efficiency and longevity.

Provides instructions for checking and replacing unit filters monthly.

States that motors are lubricated at the factory and require no further lubrication.

References a table for manifold pressures and figures to locate pressure ports.

Details the procedure for cleaning the unit's burners.

Describes how to check and clean the combustion air inducer for proper operation.

Provides instructions for removing and cleaning the flue box cover and tubes.

Advises contacting a service technician if the unit is inoperative and lists checks before calling.

Lists various parts that can be ordered and specifies required information for ordering.

Specifies the range of unit sizes covered by these installation instructions.

Contains critical safety warnings and precautions for installation and operation.

Provides essential clearance dimensions for installation based on unit model.

Details procedures for connecting the gas supply, including valve and drip leg installation.

Outlines procedures for safely testing gas piping connections and operating pressures.

Explains how to apply derates for units installed at higher altitudes.

Describes how to adjust manifold pressures for two-stage gas valves.

Provides a method for approximately determining gas flow using a gas meter.

Directs the user to the operating instruction plate for details on gas heat operation.

Presents a typical wiring schematic for the gas heat section of the unit.

Shows a typical wiring schematic for the entire unit, including components and connections.

Lists various parts that can be ordered and specifies required information for ordering.

Provides an overview of the M2 controller, support contact, and installation notes.

Covers firmware updates, controller board layout, and wiring connections.

Explains LED indicators, startup, menu navigation, alarms, and display functions.

Details accessing diagnostic tests, unit data, and configuring system settings and setpoints.

Guides the installation and configuration of the economizer, including modes and setpoints.

Provides overview, support contact, and version requirements for the LonTalk Module Kit.

Describes the module's function and details the physical installation process.

Covers wiring, sensor installation, controller setup, and network communication checks.

Details network setup, variables, integration, and handling connection failures.

Specifies the geographical coverage of the Lennox Quality Care Program warranty.

A critical warning stating that failure to maintain equipment voids the warranty.

Lists the Lennox heating and cooling equipment covered under the Limited Warranty.

Details the one-year warranty coverage for components based on original installation and manufacturing defects.

Outlines extended warranty coverage for specific components beyond the initial period.

Explains the manufacturer's options if a covered component is no longer available.

Lists components that are not protected by the warranty, such as filters and belts.

Specifies that repairs must be made with authorized parts by licensed service contractors.

Emphasizes the importance of proper installation, operation, and maintenance to avoid voiding the warranty.

Outlines the steps required to initiate a warranty claim, including information needed and dealer contact.

| Refrigerant | R-410A |

|---|---|

| Voltage | 208/230V |

| Phase | 1 |

| Compressor Type | Scroll |

| Cooling Capacity | 36000 BTU/h |

Loading...

Loading...