Page 46

LGH/LCH036, 048, 060, 072

G-Condenser Coil

All-Aluminum Coils -

Clean condenser coil annually with water and inspect

monthly during the cooling season.

Clean the all-aluminum coil by spraying the coil steadily

and uniformly from top to bottom. Do not exceed 900 psi

or a 45 angle; nozzle must be at least 12 inches from the

coil face. Take care not to fracture the braze between the

fins and refrigerant tubes. Reduce pressure and work

cautiously to prevent damage.

Fin/Tube Coils -

Clean condenser coil annually with detergent or

commercial coil cleaner and inspect monthly during the

cooling season.

Condenser coils are made of single and two formed slabs.

On units with two slabs, dirt and debris may become

trapped between the slabs. To clean between slabs,

carefully separate coil slabs and wash them thoroughly.

See figure 36. Flush coils with water following cleaning.

Note - Remove all screws and gaskets prior to cleaning

procedure and replace upon completion.

H-Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

dirt or dust. Turn off power before attempting to remove

access panel or to clean blower wheel.

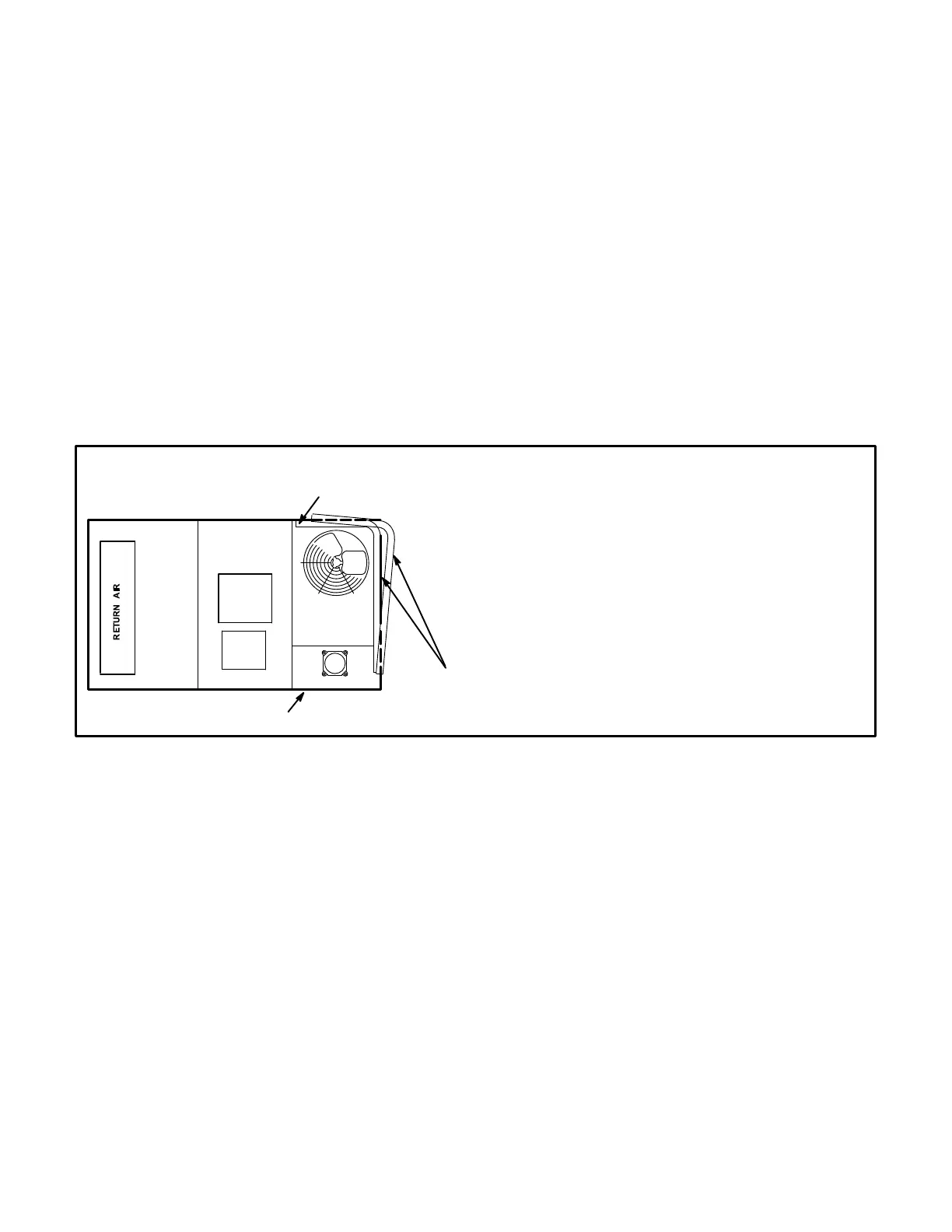

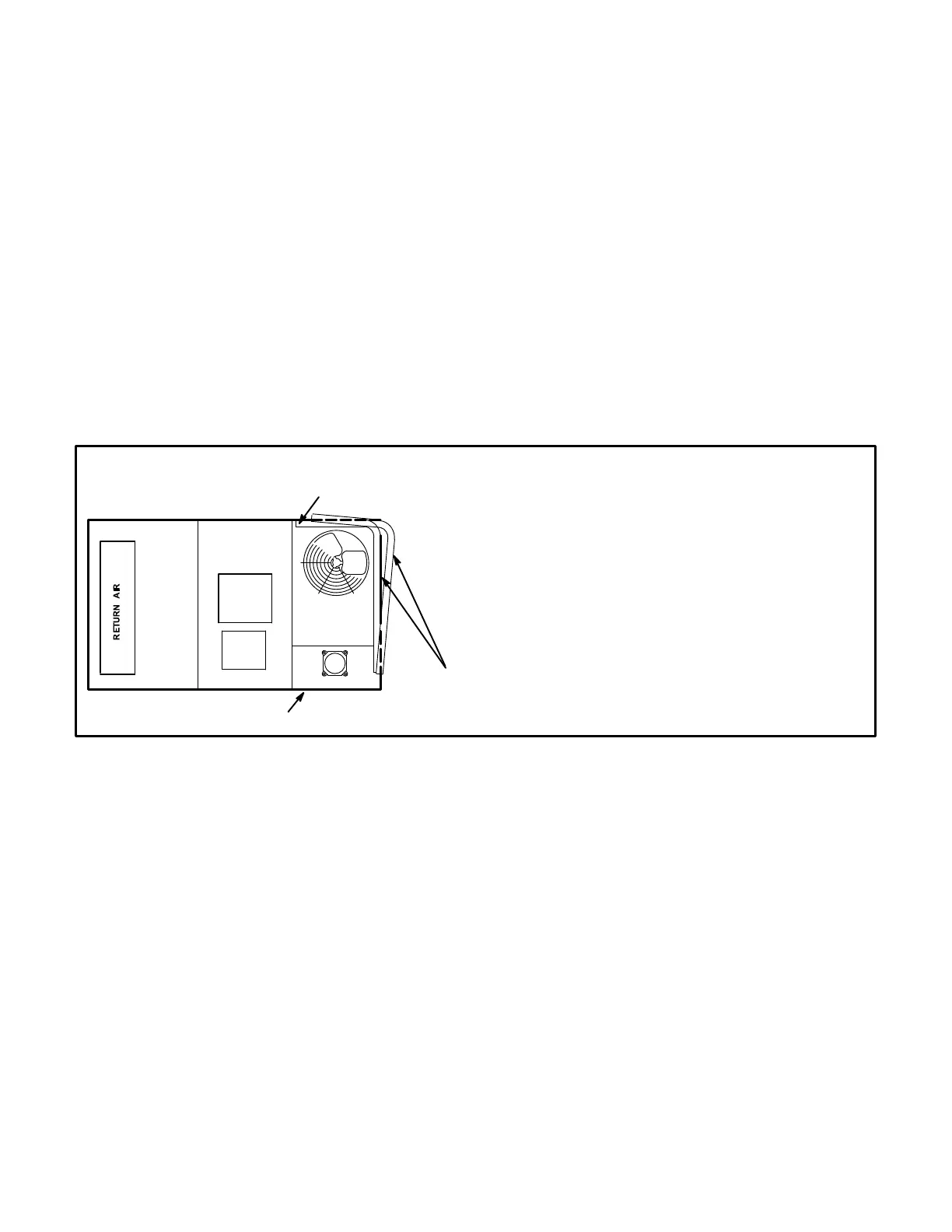

TOP VIEW

CONDENSER

COILS

BLOWER

CONDENSER ACCESS PANEL

FIGURE 36

ENDPLATE IS SECURED

TO MULLION

1- Remove unit top panel and condenser section access

panel.

2- Remove screws securing coil end plate to mullion.

3- Remove wire ties connecting coils slabs and separate

slabs 3-4” (76-102mm).

4- Clean coils with detergent or commercial coil cleaner.

5- Rinse thoroughly with water and reassemble

. Use

field-provided wire ties to connect coil slabs.

CLEAN CONDENSER COIL - UNITS WITH FIN/TUBE COILS

SUPPLY

AIR

Loading...

Loading...