Page 17

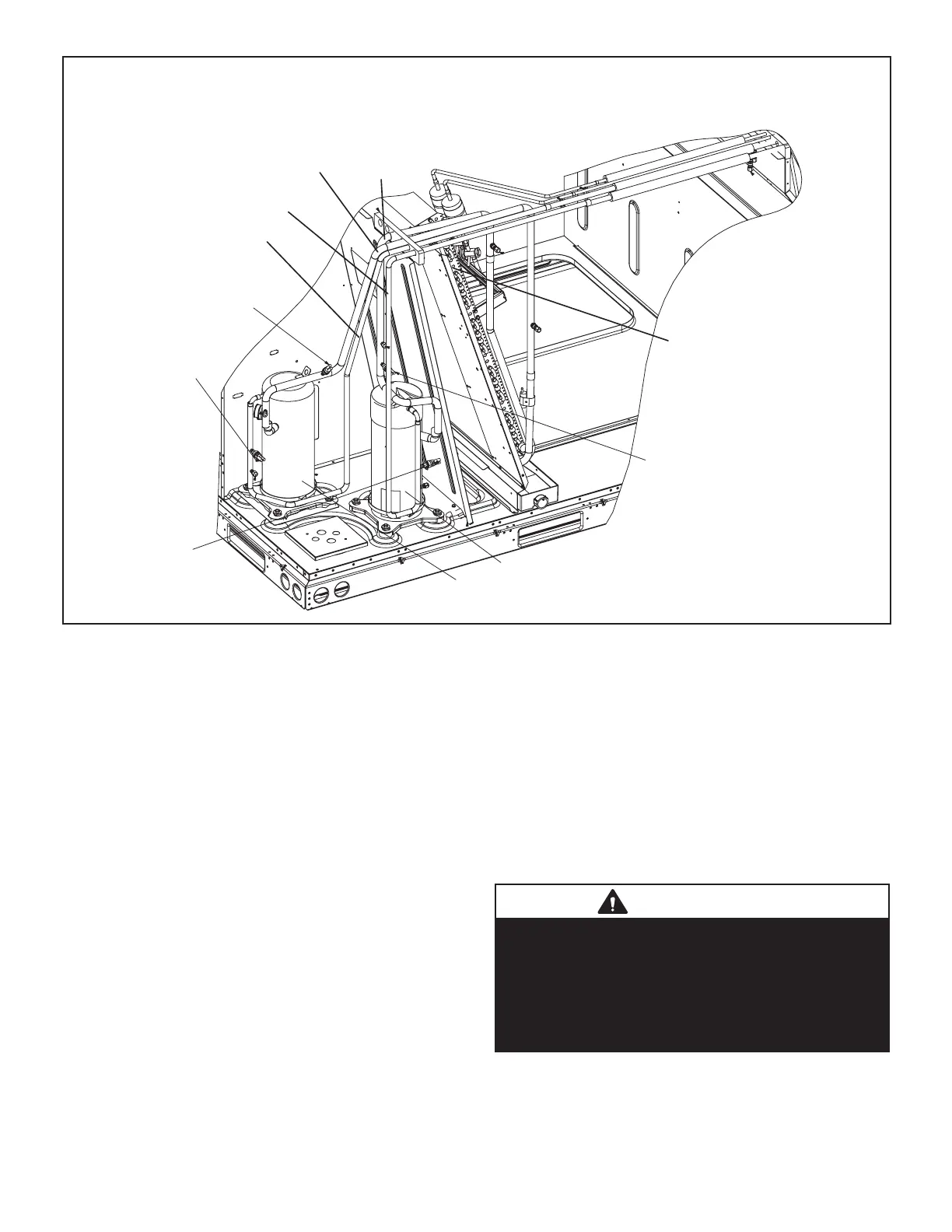

PLUMBING, COMPRESSOR AND REFRIGERANT CIRCUITS DETAIL

FIGURE 6

Low Pressure Switch

S87

Low Pressure Switch

S88

High Pressure

Switch

S4

High Pressure

Switch

S7

Evaporator Coil

Compressor

B1

Compressor

B2

Discharge Line

Stage 1

Discharge Line

Stage 2

Suction Line

Stage 1

Suction Line

Stage 2

B-Cooling Components

High efficiency units use independent cooling circuits con

sisting of separate compressors, condenser coils and

evaporator coils. See figure 6. Units are equipped with

ECM direct drive blowers which draw air across the evapo

rator during unit operation..

On all units the evaporators are slab type and are row split..

Each evaporator uses a thermostatic expansion valve as

the primary expansion device..

In all units, each compressor is protected by a crankcase

heater, high pressure switch and low pressure switch. Ad

ditional protection is provided by by thermistors for low am

bient control and freezing prevention.

Cooling may be supplemented by a factory‐ or field‐in

stalled economizer.

1-Compressors B1, B2

Units are equipped with two scroll compressors and two in

dependent cooling circuits. B1 is 2-stage compressor, with

L34 to switching between part load and full load, B2 is sin

gle stage compressor. Compressor capacity may vary from

stage to stage. In all cases, the capacity of each compres

sor is added to reach the total capacity of the unit. See

“SPECIFICATIONS” and “ELECTRICAL DATA” (table of

contents) or compressor nameplate for compressor speci

fications.

WARNING

Electrical shock hazard. Compressor must be

grounded. Do not operate without protective cover

over terminals. Disconnect power before removing

protective cover. Discharge capacitors before ser

vicing unit. Failure to follow these precautions could

cause electrical shock resulting in injury or death.

Loading...

Loading...