Page 40

VII-ACCESSORIES

The accessories section describes the application of most

of the optional accessories which can be factory or field in

stalled to the LGT units.

A-Mounting Frames

When installing units on a combustible surface for down

flow discharge applications, a C1CURB roof mounting

frame is used. The roof mounting frames are recommend

ed in all other applications but not required. If the LGT units

are not mounted on a flat (roof) surface, they MUST be sup

ported under all edges and under the middle of the unit to

prevent sagging. The units MUST be mounted level within

1/16” per linear foot or 5mm per meter in any direction.

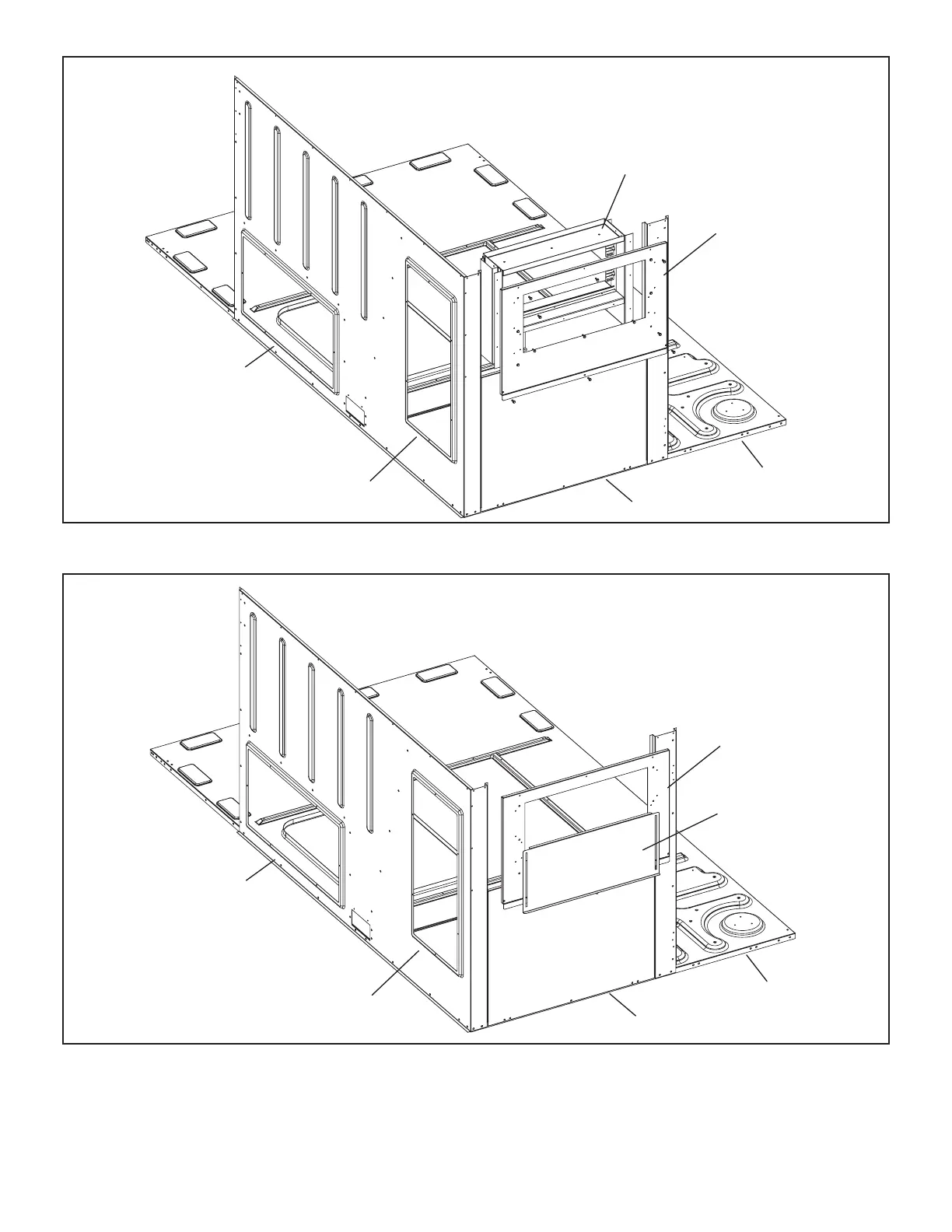

The assembled C1CURB mounting frame is shown in fig

ure 27. Refer to the roof mounting frame installation instruc

tions for details of proper assembly and mounting. The roof

mounting frame MUST be squared to the roof and level be

fore mounting. Plenum system MUST be installed before

the unit is set on the mounting frame. Typical roof curbing

and flashing is shown in figure 28. Refer to the roof mount

ing frame installation instructions for proper plenum con

struction and attachment.

FIGURE 27

ASSEMBLED ROOF MOUNTING FRAME

SUPPLY AIR

OPENING

RETURN AIR

OPENING

B-LP / Propane Kit

Natural to LP /propane kit includes a spring kit and three

stickers. In addition, the LP kit contains either six, nine, or

eleven burner orifices. For more detail refer to the natural to

LP gas changeover kit installation instructions.

C-Dirty Filter Switch S27

The dirty filter switch senses static pressure increase indi

cating a dirty filter condition. The switch is N.O. and closes

at 1” W.C. (248.6 Pa) The switch is mounted on the top filter

channel corner. Wiring for the dirty filter switch is shown on

the temperature control section (C2) wiring diagram in back

of this manual.

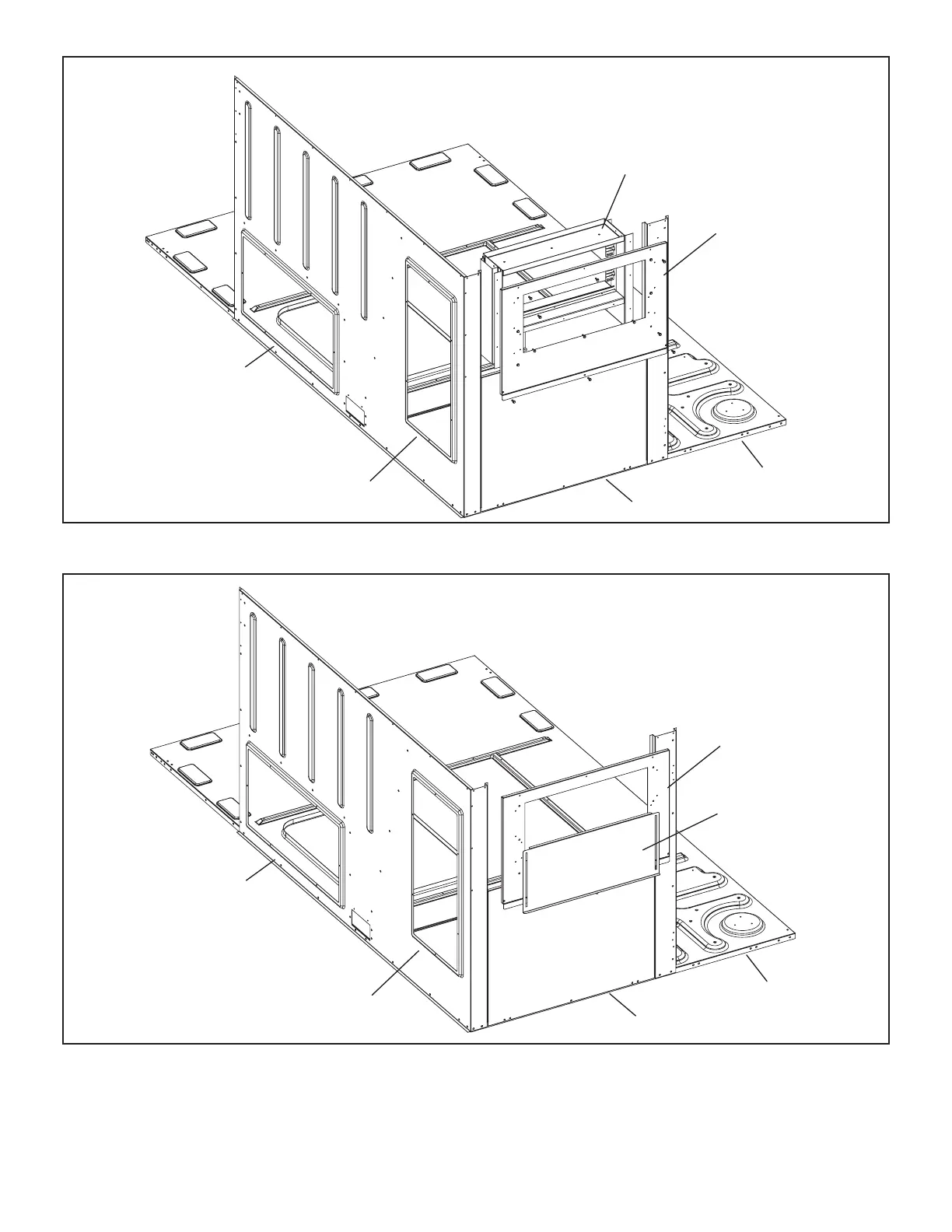

FIGURE 28

ROOF

MOUNTING FRAME

(Extends around entire

perimeter of unit)

FIBERGLASS

INSULATION

(Furnished)

COUNTER FLASHING

(Field Supplied)

UNIT BASE

BOTTOM

RIGID INSULATION

(Field Supplied)

ROOFING

MATERIAL

CANT STRIP

(Field Supplied)

NAILER STRIP

(Furnished)

UNIT BASE

RAIL

TYPICAL FLASHING DETAIL

D-Transitions

Optional supply/return transitions LASRT08/10 is available

for use with the LGT 7.5 ton units and LASRT10/12 is avail

able for the 8.5 and 10 ton units, utilizing optional C1CURB

roof mounting frames. LGT 12.5 ton units will use LASRT15

with C1CURB roof mounting frame. Transition must be in

stalled in the C1CURB mounting frame before mounting

the unit to the frame. Refer to the manufacturer's instruc

tions included with the transition for detailed installation

procedures.

E-LAOAD(M) Outdoor Air Dampers (all

units)

LAOAD(M) consists of a set of dampers which may be man

ually or motor (M) operated to allow up to 25 percent out

side air into the system at all times (see figure 29 or 30). Ei

ther air damper can be installed in LGT units. Washable

filter supplied with the outdoor air dampers can be cleaned

with water and a mild detergent. It should be sprayed with

Filter Handicoater when dry prior to re-installation.

F-Supply and Return Diffusers (all units)

Optional flush mount diffuser/return FD11 and extended

mount diffuser/return RTD11 are available for use with all

LGT units. Refer to manufacturer's instructions included

with transition for detailed installation procedures.

G-Blower Proving Switch S52

The blower proving switch monitors blower operation and

locks out the unit in case of blower failure. The switch is

N.O. and closes at .14” W.C. (34.9 Pa) The switch is mount

ed on the upper left hand corner of the blower deck. Wiring

for the blower proving switch is shown on the temperature

control section (C2) wiring diagram in back of this manual.

Loading...

Loading...