Page 24

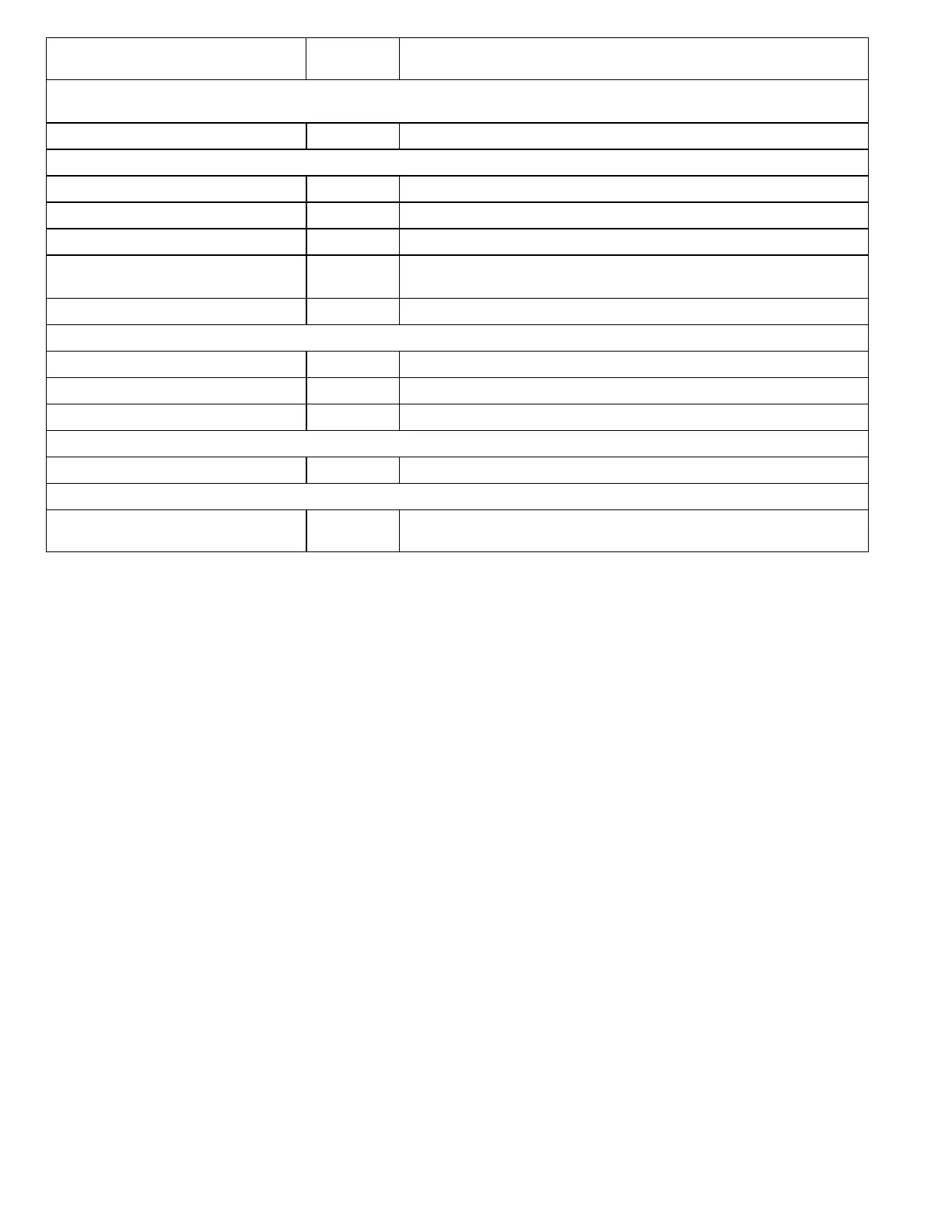

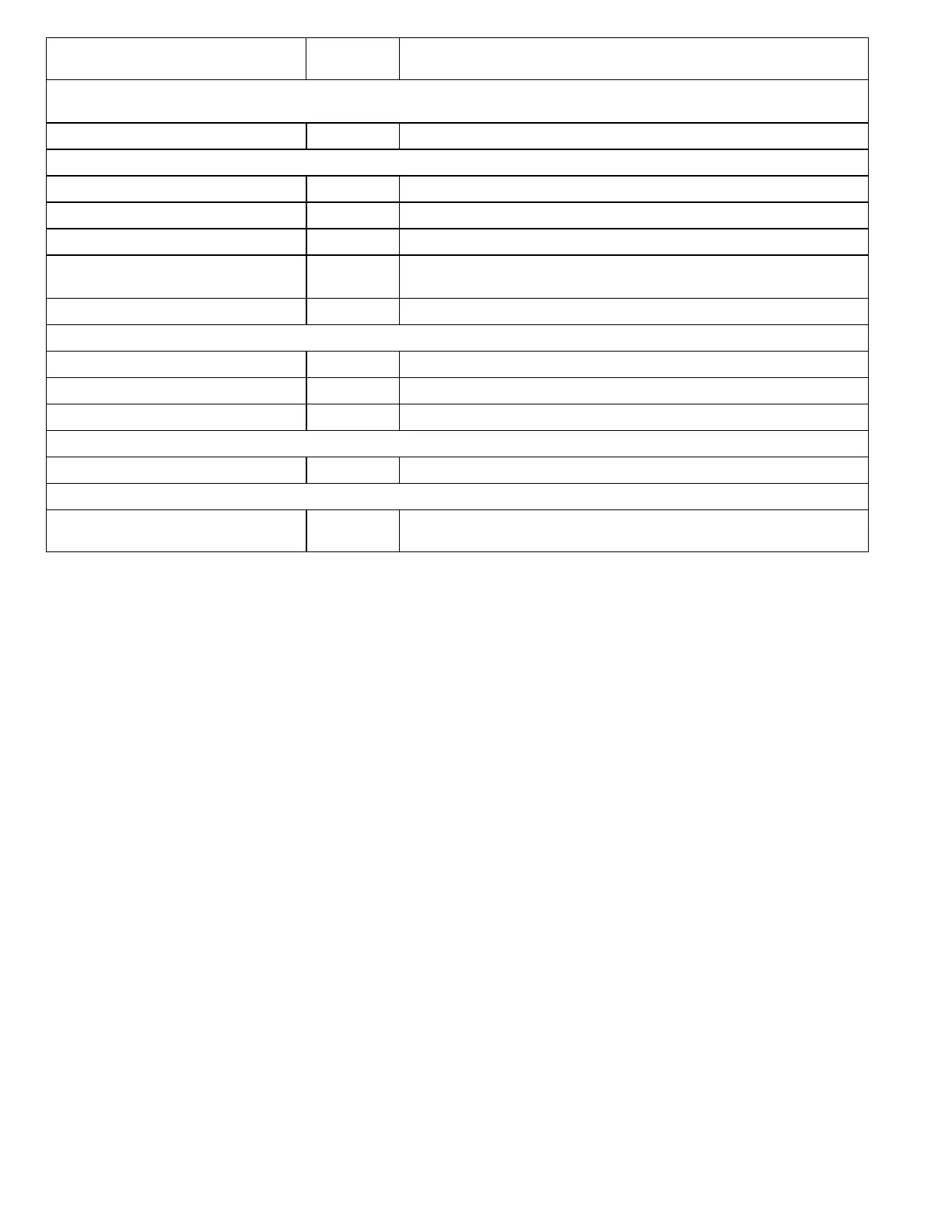

Parameter

Field

Setting

Description

Note: Any changes to Smoke CFM setting must be adjusted before the other CFM settings. Use SETTINGS > RTU OP

TIONS > EDIT PARAMETERS = 12 for EBM, 6 for ECM

BLOWER SMOKE CFM % Percentage of RPM for blower smoke speed.

SETUP > TEST & BALANCE > BLOWER

BLOWER HEATING HIGH CFM % Percentage of RPM for blower heating high speed.

BLOWER HEATING LOW CFM % Percentage of RPM for blower heating low speed (P volt gas heat only).

BLOWER COOLING HIGH CFM % Percentage of RPM for blower cooling high speed.

BLOWER COOLING LOW CFM %

Percentage of RPM for blower cooling low speed and vent speed for stan

dard static blowers.

BLOWER VENTILATION CFM % Percentage of RPM for high static blower ventilation speed.

SETUP > TEST & BALANCE > DAMPER

BLOWER HIGH CFM DAMPER POS % % Minimum damper position for high speed blower operation. Default 0%.

BLOWER LOW CFM DAMPER POS % % Minimum damper position for low speed blower operation. Default 0%.

POWER EXHAUST DAMPER POS % % Minimum damper position for low power exhaust operation. Default 50%.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS = 216

POWER EXHAUST DEADBAND % % Deadband % for power exhaust operation. Default 10%.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS = 10 (Applies to Thermostat Mode ONLY)

FREE COOLING STAGE-UP DELAY sec

Number of seconds to hold blower at low speed before switching to blower

at high speed. Default 300 seconds.

Installer: Record any parameter changes under “Field Setting” column. Settings need to be recorded by installer for use when Unit Con

troller is replaced or reprogrammed.

Loading...

Loading...