Page 33

Electrical

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can aect electronic components.

Take precautions during furnace installation and service

to protect the furnace’s electronic controls. Precautions

will help to avoid control exposure to electrostatic

discharge by putting the furnace, the control and the

technician at the same electrostatic potential. Neutralize

electrostatic charge by touching hand and all tools on an

unpainted unit surface, such as the gas valve or blower

deck, before performing any service procedure.

WARNING

Electric Shock Hazard. Can cause injury or

death. Unit must be properly grounded in

accordance with national and local codes.

WARNING

Fire Hazard. Use of aluminum wire with this product may

result in a re, causing property damage, severe injury

or death. Use copper wire only with this product..

CAUTION

Failure to use properly sized wiring and circuit breaker

may result in property damage. Size wiring and circuit

breaker(s) per Product Specications bulletin (EHB) and

unit rating plate.

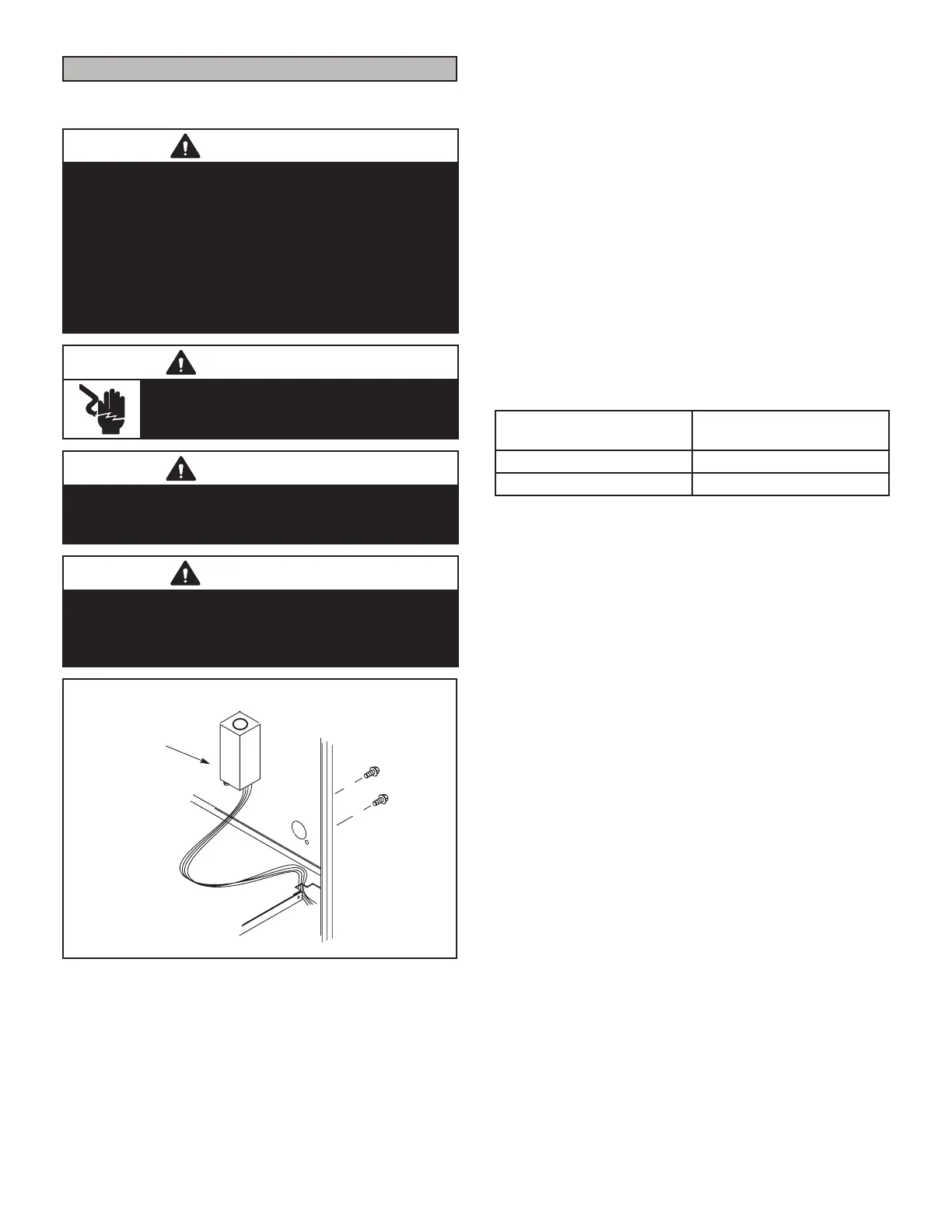

INTERIOR MAKE-UP BOX INSTALLATION

MAKE-UP

BOX

Right Side

FIGURE 51

The unit is equipped with a eld make-up box on the left

hand side of the cabinet. The make-up box may be moved

to the right side of the furnace to facilitate installation. If

the make-up box is moved to the right side, clip the wire

ties that bundle the wires together. The excess wire must

be pulled into the blower compartment. Secure the excess

wire to the existing harness to protect it from damage.

See FIGURE 52 and FIGURE 53 for thermostat wiring in

communicating applications. TABLE 15 shows DIP switch

and on-board link settings for non-communicating ther-

mostat applications. Typical wiring schematic is shown in

FIGURE 54.

1 - The power supply wiring must meet Class I

restrictions. Protected by either a fuse or circuit

breaker, select circuit protection and wire size

according to unit nameplate.

NOTE - Unit nameplate states maximum current draw.

See TABLE 12 for maximum over-current protection.

TABLE 12

SL99UHV Model

Maximum Over-Current

Protection Amps

070-36B, 090-36C, 090-48C 15

090-60C, 110-60C, 135-60D 20

2 - Holes are on both sides of the furnace cabinet to

facilitate wiring.

3 - Install a separate (properly sized) disconnect switch

near the furnace so that power can be turned o for

servicing.

4 - Before connecting the thermostat or the power

wiring, check to make sure the wires will be long

enough for servicing at a later date. Remove the

blower access panel to check the length of the wire.

5 - Complete the wiring connections to the equipment.

Use the provided unit wiring and eld wiring diagram

shown in FIGURE 54 and TABLE 15. Use 18-gauge

wire or larger that is suitable for Class II rating for

thermostat connections.

NOTE - Do NOT make a wire connection between

the room thermostat L terminal and the L terminal

of the SLP99UHV integrated control unless this

is a communicating thermostat installation with

a non-communicating outdoor unit.

6 - Electrically ground the unit according to local codes

or, in the absence of local codes, according to the

current National Electric Code (ANSI/NFPA No. 70)

for the USA and current Canadian Electric Code

part 1 (CSA standard C22.1) for Canada. A green

ground wire is provided in the eld make-up box.

7 - One line voltage “EAC” 1/4” spade terminal is

provided on the furnace integrated control. Any

electronic air cleaner or other 120V accessory rated

up to one amp can be connected to this terminal

with the neutral leg

Loading...

Loading...