Page 54

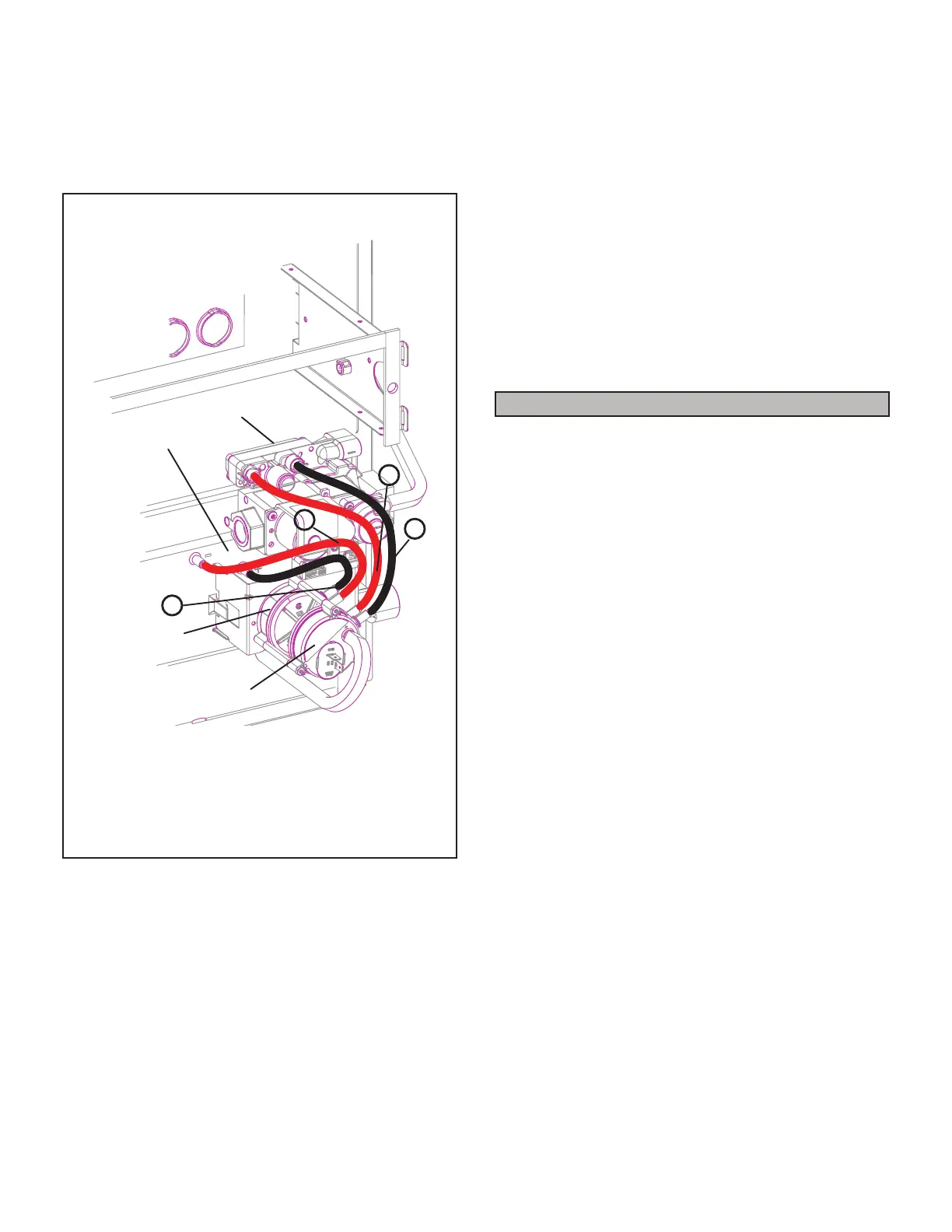

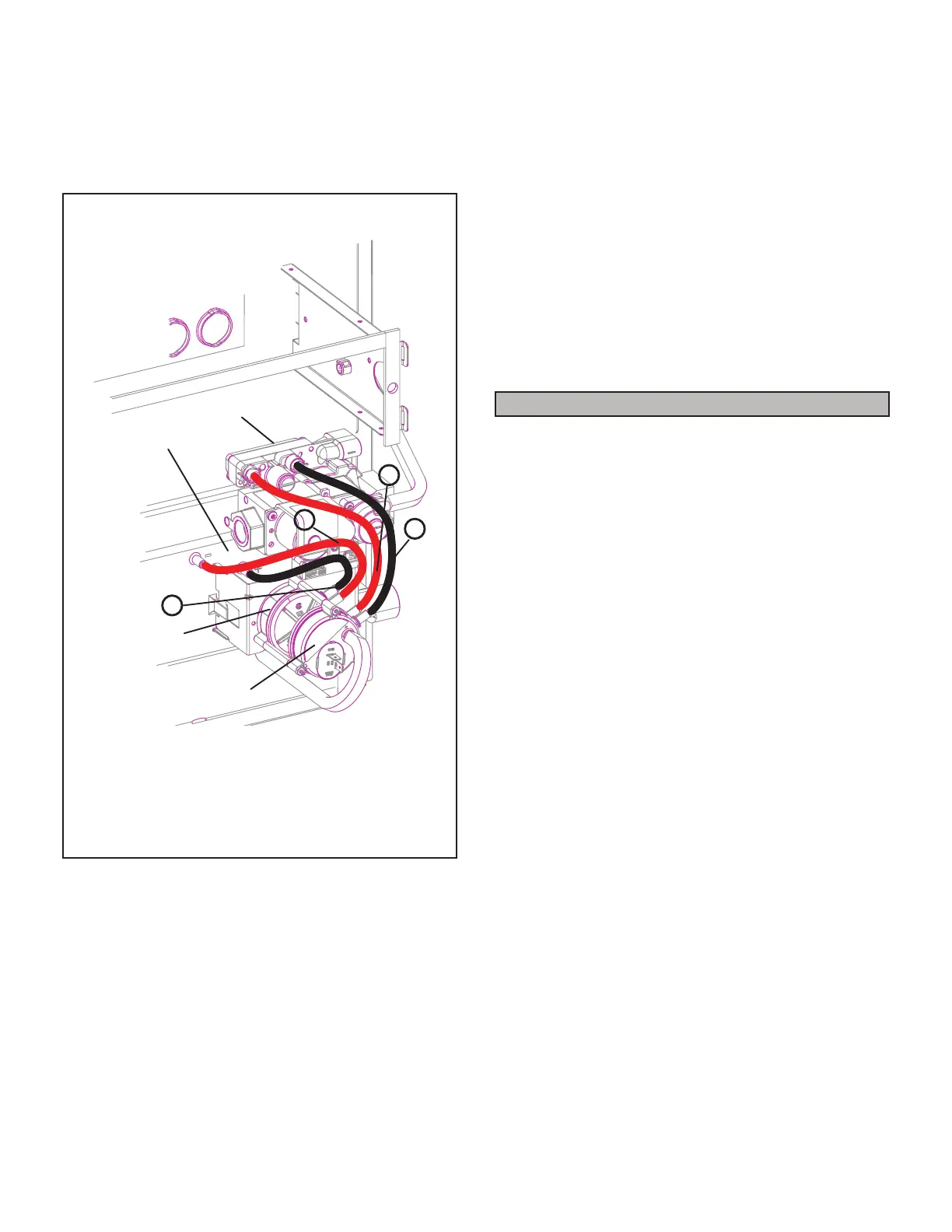

Pressure Switches (Two)

The pressure switches are located on the cold end header

box. These switches check for proper combustion air in-

ducer operation before allowing ignition trial. The switch-

es are factory-set and require no adjustment. Pressure

switch tubing installation is critical for safe operation. See

FIGURE 59.

PRESSURE SWITCH TUBING INSTALLATION

(shown in upflow position)

Gas Valve

Cold End Header Box

High-Fire

Pressure Switch

Low-Fire

Pressure Switch

1

2

3

4

1 - Black tubing from front port on low-fire pressure switch to

positive port on the gas valve.

2 - Red and black tubing from rear port on low-fire pressure

switch to the negative port on the gas valve.

3 - Red and black tubing from front port on high-fire pressure

switch to negative port on cold end header box.

4 - Black tubing from rear port on high-fire pressure switch to

positive port on cold end header box.

FIGURE 59

Temperature Rise

After the furnace has been started and supply and return

air temperatures have been allowed to stabilize, check

the temperature rise with the unit operating at 100 per-

cent ring rate. See “Duct System” on page 10 for in-

stalling the optional discharge air sensor (shipped with the

furnace) used to measure temperature rise. If necessary,

adjust the blower speed to maintain the temperature rise

within the range shown on the unit nameplate. See TABLE

24 on page 48 for allowable heating speeds.Increase

the blower speed to decrease the temperature. Decrease

the blower speed to increase the temperature rise. Failure

to adjust the temperature rise may cause erratic limit op-

eration.

Electronic Ignition

The integrated control has an added feature of an inter-

nal Watchguard control. The feature serves as an auto-

matic reset device for ignition control lockout caused by

ignition failure. This type of lockout is usually due to low

gas line pressure. After one hour of continuous thermostat

demand for heat, the Watchguard will break and remake

thermostat demand to the furnace and automatically reset

the control to begin the ignition sequence.

Exhaust and Air Intake Pipe

1 - Check exhaust and air intake connections for

tightness and to make sure there is no blockage.

2 - Are pressure switches closed? Obstructed exhaust

pipe will cause unit to shut o at pressure switches.

Check termination for blockages.

3 - Reset manual ame rollout switches on burner box

cover.

Heating Sequence of Operation

The integrated control initiates a pressure switch calibra-

tion at the initial unit start-up on a call for heat. The ignition

control will also initiate a calibration any time main power

is turned o and back on and a heating demand is pres-

ent . Additional calibrations may be initiated by the ser-

vice technician during eld test sequence. The following

heating sequence of operation assumes completion of a

successful calibration.

NOTE - In communicating applications, the sequence of

operation is the same but all DIP switch settings are ove-

ridden by the thermostat.

NOTE - The thermostat selection DIP switch on the inte-

grated control is factory-set in the “TWO-STAGE” position.

Applications Using a Two-Stage Thermostat

A - Heating Sequence -- Control Thermostat Selection

DIP switch in “Two-Stage” Position (Factory Setting)

1 - On a call for heat, thermostat rst-stage contacts

close sending a signal to the integrated control. The

integrated control runs a self-diagnostic program

and checks high temperature limit switches for

normally closed contacts and pressure switches

for normally open contacts. The combustion air

inducer is energized at ignition speed, which is

approximately the same as the inducer speed at 70

percent ring rate.

2 - Once the control receives a signal that the low-

re pressure switch has closed, the combustion

air inducer begins a 15-second pre-purge in the

ignition speed.

3 - After the pre-purge is complete, a 20-second initial

ignitor warm-up period begins. The combustion air

inducer continues to operate at the ignition speed.

4 - After the 20-second warm-up period has ended,

the gas valve is energized and ignition occurs. At

the same time, the control module sends a signal to

begin an indoor blower 30-second ON-delay. When

the delay ends, the indoor blower motor is energized

at a speed that matches the ring rate. After the

10-second ignition stabilization delay expires, the

Loading...

Loading...