Page 14

505367M 04/08

Table 3. Indoor Unit Fixed Orifice Kits

Model Catalog Number Part Number Drill Size

XC14−018 97M74 100484−06 0.053

XC14−024 97M75 100484−08 0.057

XC14−030 97M76 100484−13 0.063

XC14−036 11W02 100484−22 0.073

XC14−042 97M78 100484−24 0.076

XC14−048 11W07 100484−31 0.083

XC14−060 11W11 100484−40 0.093

Use the Lennox catalog number to order a new or replacement fixed

orifice kit.

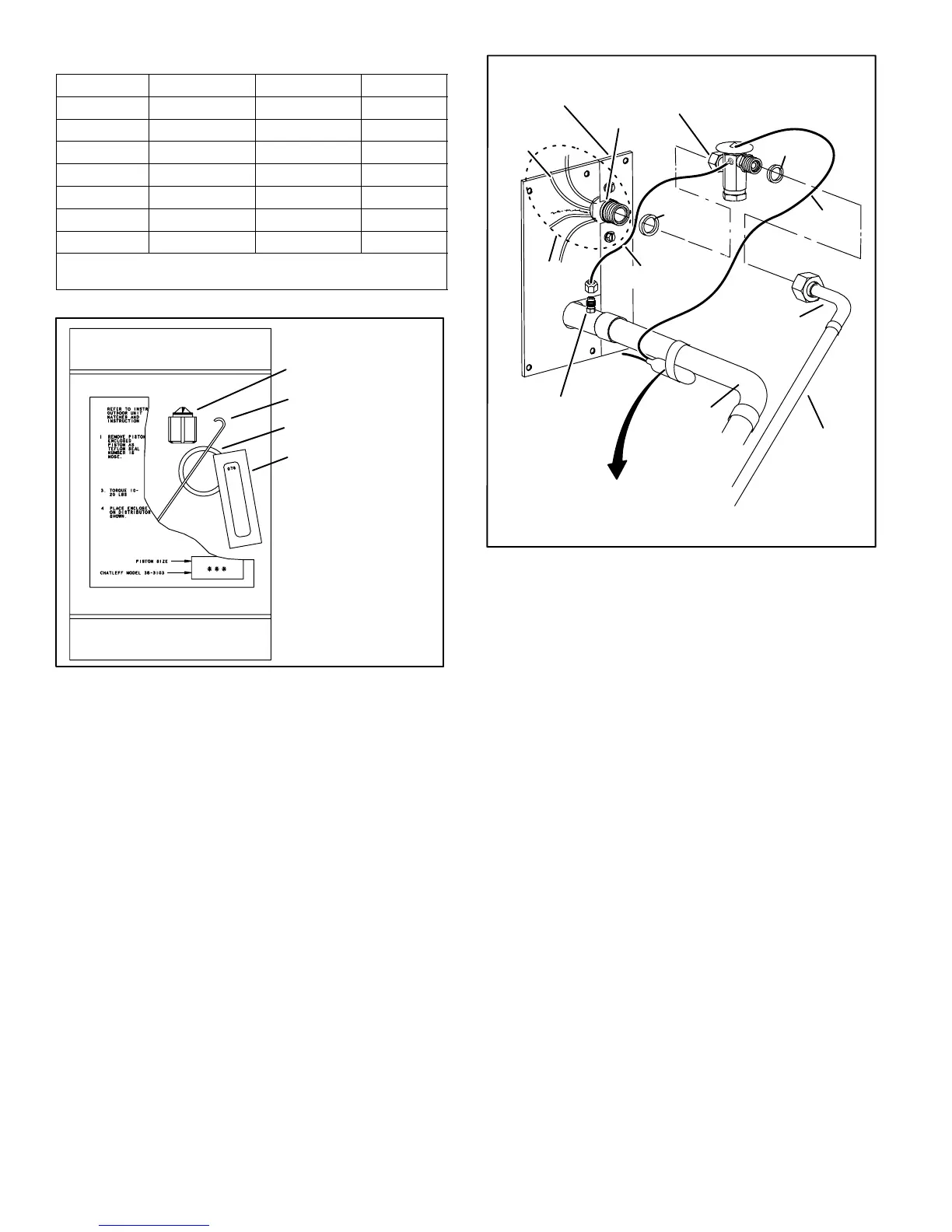

The fixed orifice kit includes the following components:

FIXED ORIFICE (1)

FIXED ORIFICE

EXTRACTOR (1)

TEFLON RING (1)

FIXED ORIFICE STICKER (1)

Figure 25. Fixed Orifice Kit Components

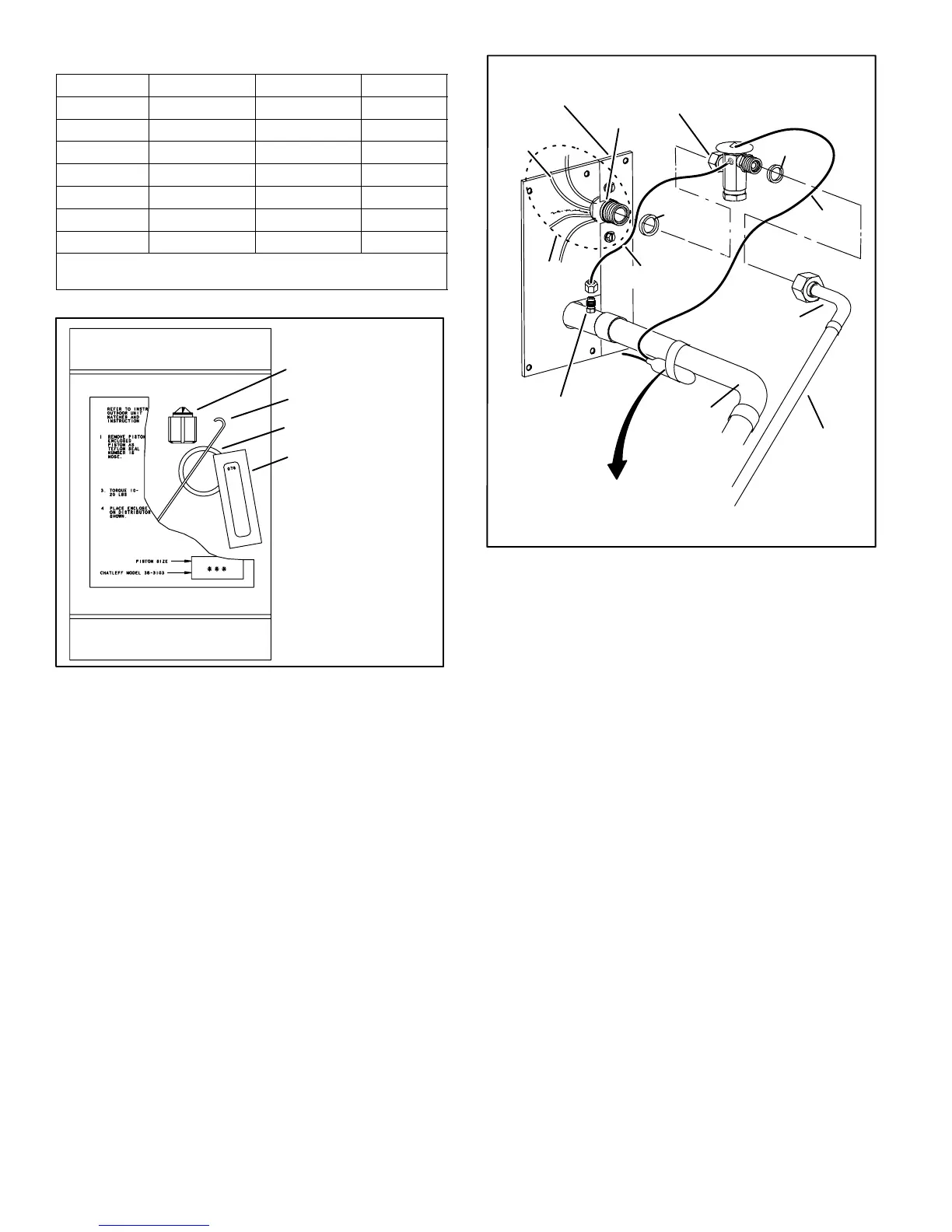

TYPICAL TXV INSTALLATION PROCEDURE

The TXV unit can be installed internal or external to the

indoor coil. In applications where an uncased coil is being

installed in a field−provided plenum, install the TXV in a

manner that will provide access for field servicing of the

TXV. Refer to Figure 26 for reference during installation of

TXV unit.

To prevent any possibility of water damage, properly

insulate all parts of the TXV assembly that may sweat due

to temperature differences between the valve and its

surrounding ambient temperatures.

TWO PIECE

PATCH PLATE

(UNCASED COIL

ONLY)

SUCTION

LINE

LIQUID LINE

ORIFICE

HOUSING

DISTRIBUTOR

TUBES

LIQUID

LINE

MALE EQUALIZER LINE

FITTING (SEE FIGURE 28

FOR FURTHER DETAILS)

SENSING

LINE

EQUALIZER

LINE

TXV

TEFLON

RING

(Uncased Coil Shown)

SENSING BULB INSULATION IS

REQUIRED IF MOUNTED EXTERNAL

TO THE COIL CASING. SEE FIGURE 27

FOR BULB POSITIONING.

STUB END

TEFLON

RING

LIQUID LINE ASSEMBLY

WITH BRASS NUT

DISTRIBUTOR

ASSEMBLY

Figure 26. Typical TXV Installation

1. Remove the field−provided fitting that temporary

reconnected the liquid line to the indoor unit’s

distributor assembly.

2. Install one of the provided Teflon rings around the

stubbed end of the TXV and lightly lubricate the

connector threads and expose surface of the Teflon

ring with refrigerant oil.

3. Attach the stubbed end of the TXV to the liquid line

orifice housing. Finger tighten and use an appropriately

sized wrench to turn an additional 1/2 turn clockwise

as illustrated in figure 23, or 20 ft−lb.

4. Place the remaining Teflon ring around the other end

of the TXV. Lightly lubricate connector threads and

expose surface of the Teflon ring with refrigerant oil.

5. Attach the liquid line assembly to the TXV. Finger

tighten and use an appropriately sized wrench to turn

an additional 1/2 turn clockwise as illustrated in figure

23, or 20 ft−lb.

Loading...

Loading...