Page 20

A−Service Valves

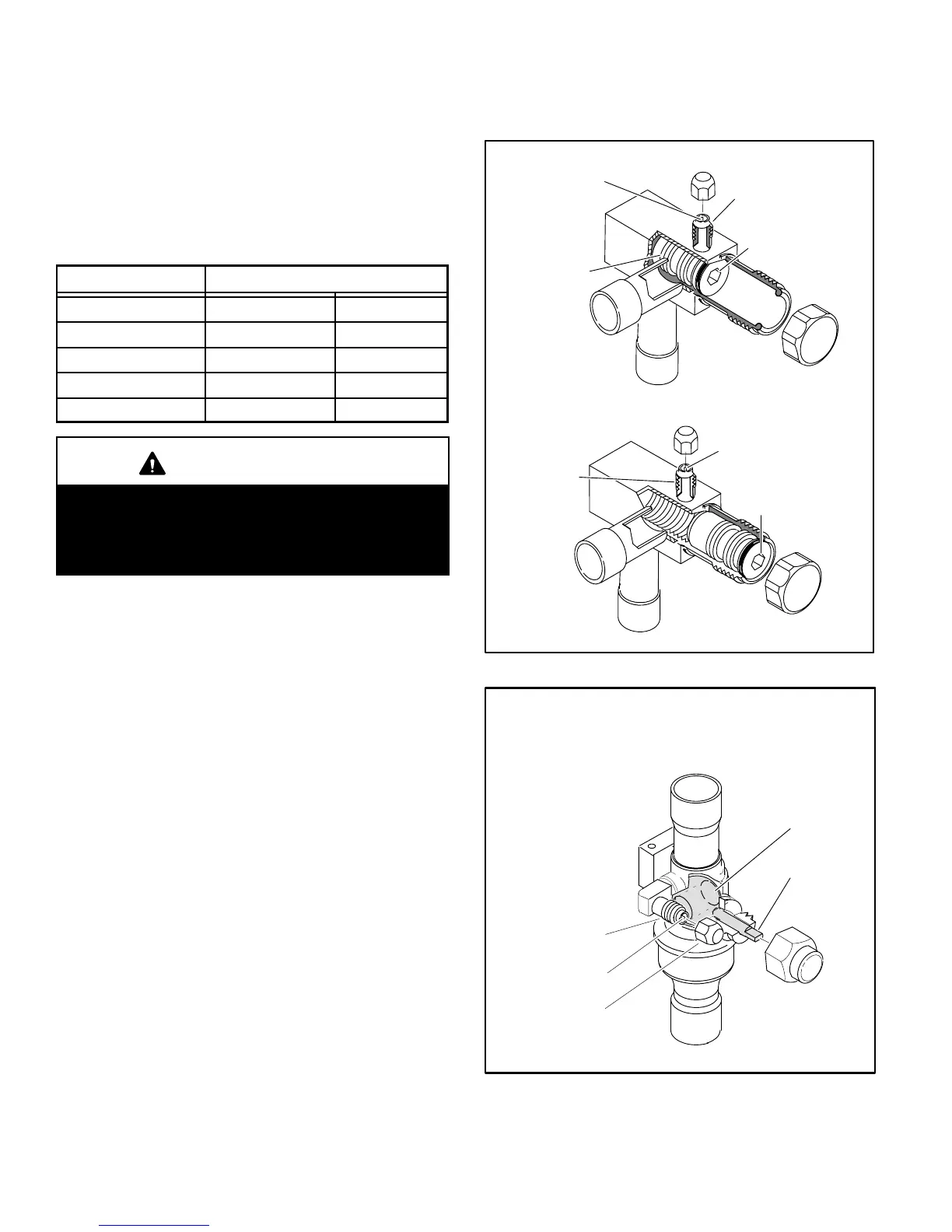

Access the liquid line and vapor line service valves (figures

21 and 22) and gauge ports are used for leak testing, eva-

cuating, charging and checking charge. See table 8 for

torque requirements.

Each valve is equipped with a service port which has a fac-

tory−installed Schrader valve. A service port cap protects

the Schrader valve from contamination and serves as the

primary leak seal.

TABLE 8

Part Recommended Torque

Service valve cap 8 ft.− lb. 11 NM

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #10 28 in.− lb. 3 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 NM

IMPORTANT

Service valves are closed to the outdoor unit and

open to line set connections. Do not open the valves

until refrigerant lines have been leak tested and

evacuated. All precautions should be exercised to

keep the system free from dirt, moisture and air.

To Access Schrader Port:

1 − Remove service port cap with an adjustable wrench.

2 − Connect gauge to the service port.

3 − When testing is complete, replace service port cap.

Tighten finger tight, then an additional 1/6 turn.

To Open Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Using service wrench and hex head extension, back

the stem out counterclockwise as far as it will go.

NOTE − Use a 3/16" hex head extension for liquid line

size.

3 − Replace stem cap and tighten it firmly. Tighten finger

tight, then tighten an additional 1/6 turn.

To Close Service Valve:

1 − Remove stem cap with an adjustable wrench.

2 − Using service wrench and hex head extension, turn

stem clockwise to seat valve. Tighten it firmly.

NOTE − Use a 3/16" hex head extension for liquid line

size.

3 − Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

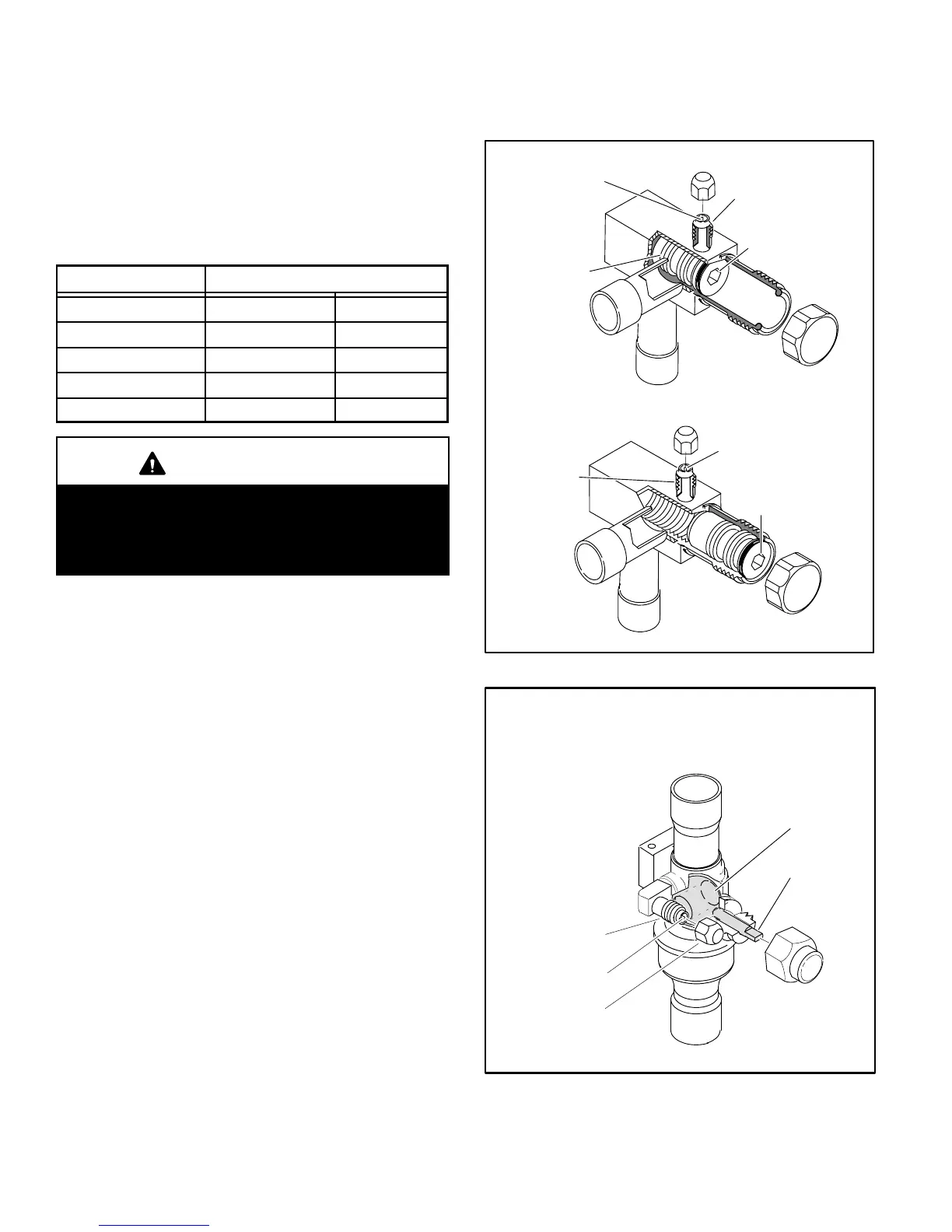

Vapor Line (Ball Type) Valve

Vapor line service valves function the same way as the oth-

er valves, the difference is in the construction. These

valves are not rebuildable. If a valve has failed, you must

replace it. A ball valve valve is illustrated in figure 22.

The ball valve is equipped with a service port with a factory−

installed Schrader valve. A service port cap protects the

Schrader valve from contamination and assures a leak−

free seal.

Front-Seated Liquid Line Service Valve

(Valve Shown

Closed)

Insert hex

wrench here

SCHRADER

VALVE

SERVICE

PORT

To outdoor coil

STEM

CAP

STEM

CAP

(VALVE front-

seated)

To outdoor coil

SCHRADER

VALVE

[open to line set

when valve is

closed (front

seated)]

(Valve Shown Open)

insert hex wrench here

To

indoor coil

SERVICE PORT CAP

SERVICE PORT

SERVICE PORT CAP

To

indoor coil

FIGURE 21

Vapor Line (Ball Type) Service Valve

(Valve Open)

FIGURE 22

BALL

(Shown

closed)

STEM

STEM

CAP

SERVICE

PORT

SCHRADER

VALVE

SERVICE

PORT CAP

To indoor coil

To outdoor coil

Use Adjustable Wrench

To close: rotate Stem

Counter-clockwise 90°.

To open: rotate Stem

Clockwise 90°.

Loading...

Loading...