Page 19

K−Crankcase Heater (HR1)

Compressors in all units are equipped with a 70 watt belly-

band type crankcase heater. HR1 prevents liquid from ac-

cumulating in the compressor. HR1 is controlled by the

crankcaseheater thermostat.

L− Crankcase heater Thermostat (S40)

Thermostat S40 controls the crankcase heater in all units.

S40 is located on the liquid line. When liquid line tempera-

ture drops below 50° F the thermostat S40 closes energizing

HR1. The thermostat will open, de−energizing HR1 once liq-

uid line temperature reaches 70° F .

III−REFRIGERANT SYSTEM

IMPORTANT

The Clean Air Act of 1990 bans the intentional vent-

ing of (CFC’s and HFC’s) as of July 1, 1992. Approved

methods of recovery, recycling or reclaiming must

be followed. Fines and/or incarceration my be levied

for noncompliance.

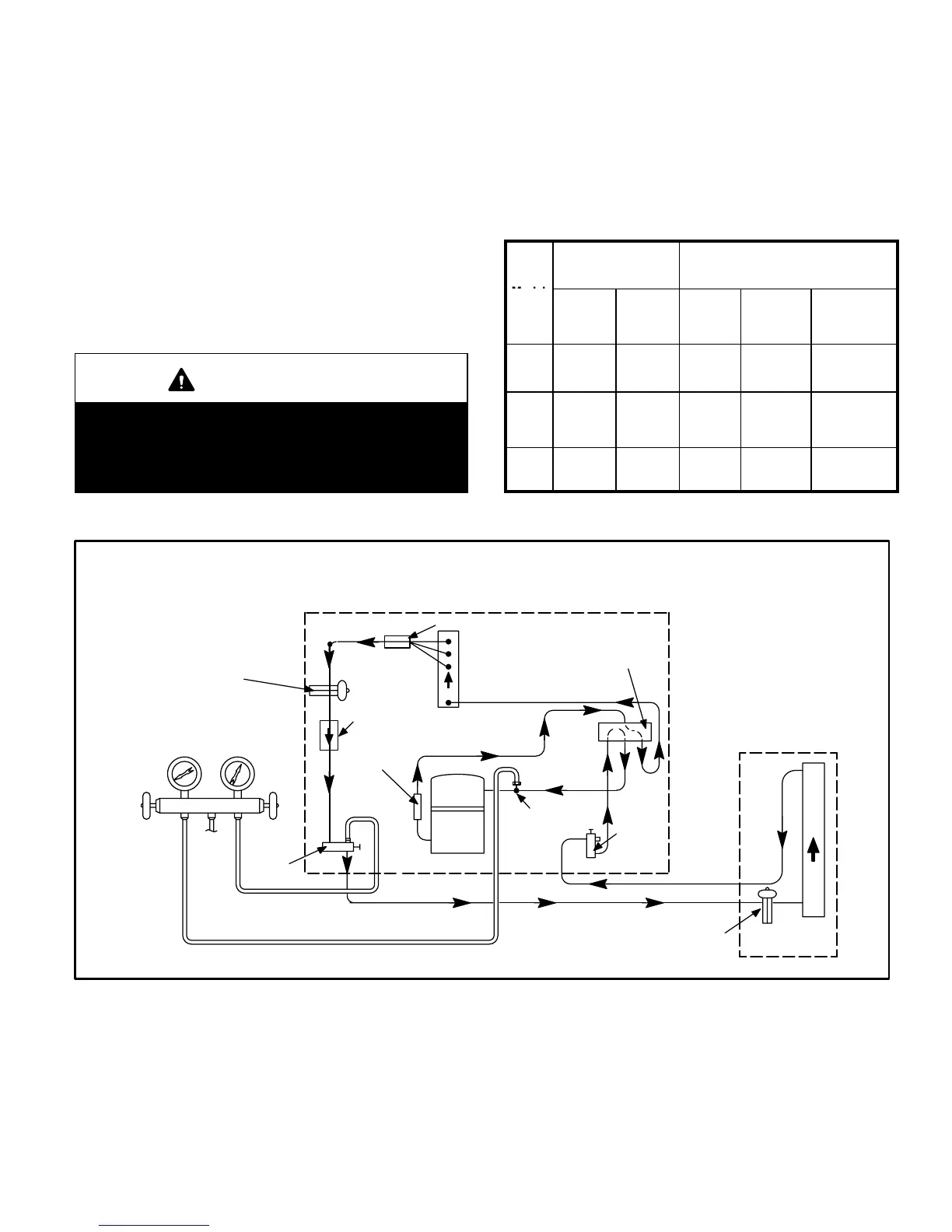

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections). Use Lennox

L15 series line sets as shown in table 7.

Separate liquid and suction service ports are provided at

the service valves for connection of gauge manifold during

charging procedure. Figure 20 shows XP19 refrigerant

flow and gauge manifold connections.

TABLE 7

Valve Field Size

Connections

Recommended Line Set

Model

Liquid

Line

Vapor

Line

Liquid

Line

Vapor

Line

L15

Line Sets

−024,−

036

3/8 in.

10 mm

7/8 in.

22 mm

3/8 in.

10 mm

7/8 in.

19 mm

L15−65

15 ft. − 50 ft.

4.6 m − 15 m

−048

3/8 in.

10 mm

1−1/8 in.

29 mm

3/8 in.

10 mm

7/8 in.

22 mm

L15−65

15 ft. − 50 ft.

4.6 m − 15 m

−060

3/8 in.

10 mm

1−1/8 in.

29 mm

3/8 in.

10 mm

1−1/8 in.

29 mm

Field

Fabricated

XP19 COOLING CYCLE

(Showing Gauge Manifold Connections)

NOTE−Use gauge ports on vapor line valve and liquid valve for evacuating refrigerant lines

and indoor coil. Use suction gauge port to measure suction pressure during charging.

OUTDOOR

COIL

EXPANSION/

CHECK VALVE

BIFLOW

FILTER / DRIER

TO

R410A

DRUM

LOW

PRESSURE

HIGH

PRESSURE

COMPRESSOR

REVERSING VALVE

VAPOR

LINE

VALVE

MUFFLER

NOTE − ARROWS INDICATE

DIRECTION OF REFRIGERANT FLOW.

REFRIGERANT WILL FLOW IN OPPOSITE

DIRECTION IN HEATING CYCLE.

SERVICE

PORT

SUCTION

EXPANSION/CHECK

VALVE

INDOOR UNIT

OUTDOOR UNIT

LIQUID

LINE

SERVICE

PORT

GAUGE MANIFOLD

DISTRIBUTOR

INDOOR

COIL

FIGURE 20

Loading...

Loading...