Page 4

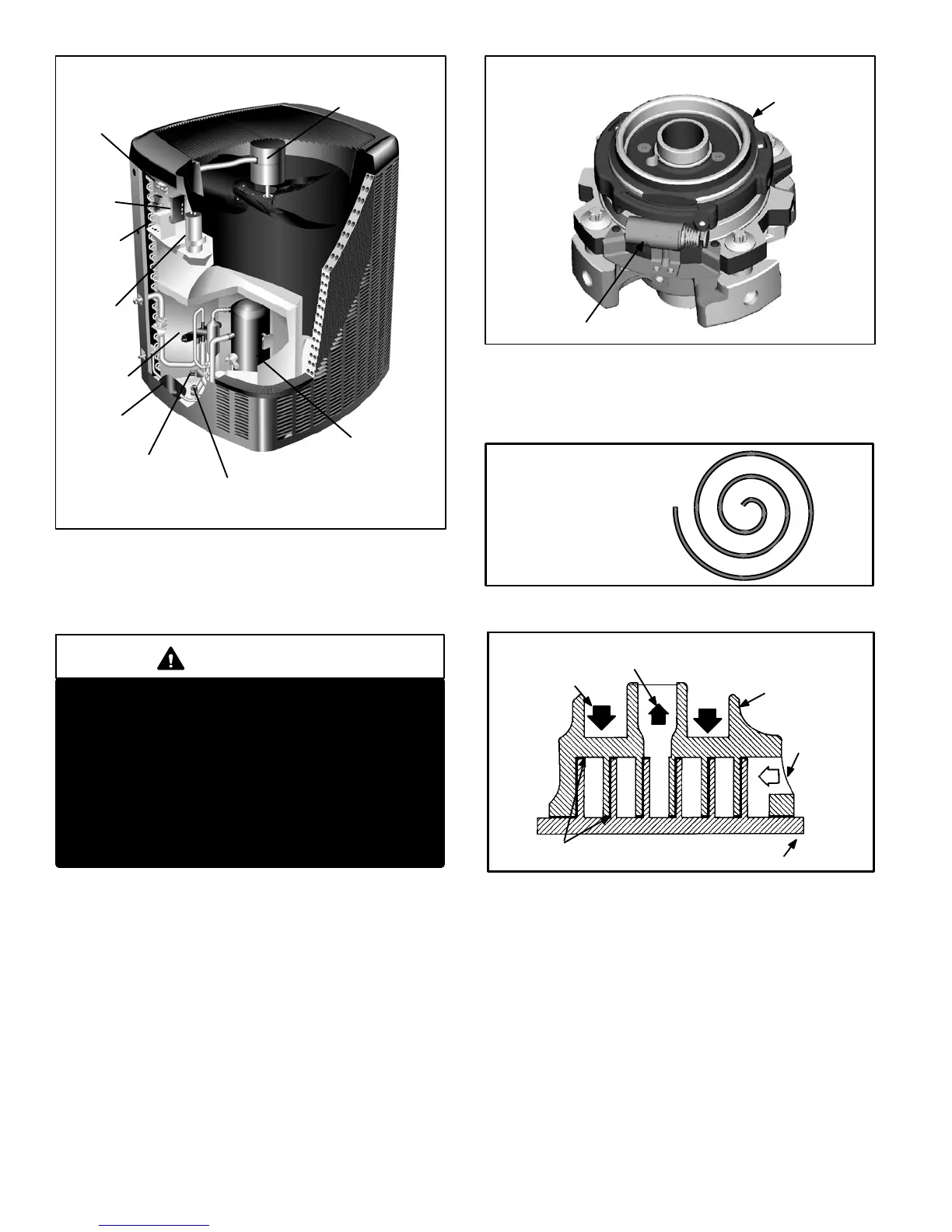

FIGURE 3

XP19 PARTS ARRANGEMENT

OUTDOOR FAN

COMPRESSOR

CONTACTOR

DEFROST

CONTROL

LSOM

LOW PRESSURE

SWITCH

HIGH PRESSURE

SWITCH

DRIER

REVERSING

VALVE

CAPACITOR

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit instal-

lation and service to protect the unit’s electronic

controls. Precautions will help to avoid control

exposure to electrostatic discharge by putting

the unit, the control and the technician at the

same electrostatic potential. Neutralize electro-

static charge by touching hand and all tools on an

unpainted unit surface before performing any

service procedure.

A−Two−Stage Scroll Compressor (B1)

The scroll compressor design is simple, efficient and re-

quires few moving parts. A cutaway diagram of the scroll

compressor is shown in figure 1.The scrolls are located in

the top of the compressor can and the motor is located just

below. The oil level is immediately below the motor.

The scroll is a simple compression concept centered

around the unique spiral shape of the scroll and its inherent

properties. Figure 5 shows the basic scroll form. Two iden-

tical scrolls are mated together forming concentric spiral

shapes (figure 6). One scroll remains stationary, while the

other is allowed to orbit" (figure 7). Note that the orbiting

scroll does not rotate or turn but merely orbits" the station-

ary scroll.

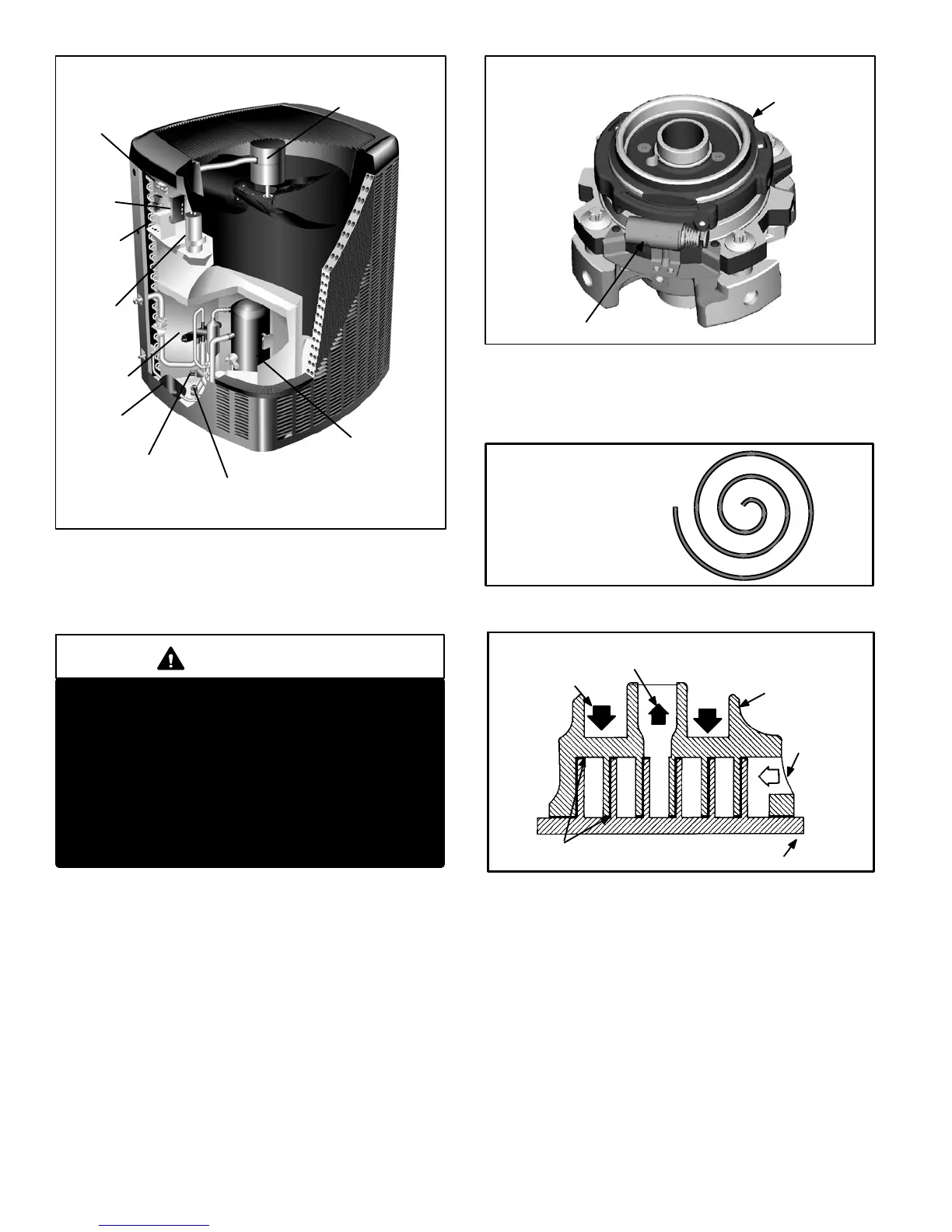

FIGURE 4

TWO−STAGE MODULATED SCROLL

slider ring

solenoid actuator coil

FIGURE 5

SCROLL FORM

FIGURE 6

STATIONARY

SCROLL

ORBITING SCROLL

DISCHARGE

SUCTION

CROSS−SECTION OF SCROLLS

TIPS SEALED BY

DISCHARGE PRESSURE

DISCHARGE

PRESSURE

The counterclockwise orbiting scroll draws gas into the out-

er crescent shaped gas pocket created by the two scrolls

(figure 7 − 1). The centrifugal action of the orbiting scroll

seals off the flanks of the scrolls (figure 7 − 2). As the orbiting

motion continues, the gas is forced toward the center of the

scroll and the gas pocket becomes compressed (figure 7

−3). When the compressed gas reaches the center, it is dis-

charged vertically into a chamber and discharge port in the

top of the compressor (figure 7 − 4). The discharge pressure

forcing down on the top scroll helps seal off the upper and

lower edges (tips) of the scrolls (figure 6). During a single or-

bit, several pockets of gas are compressed simultaneously

providing smooth continuous compression.

Loading...

Loading...