Page 5

507111-02 2/2015

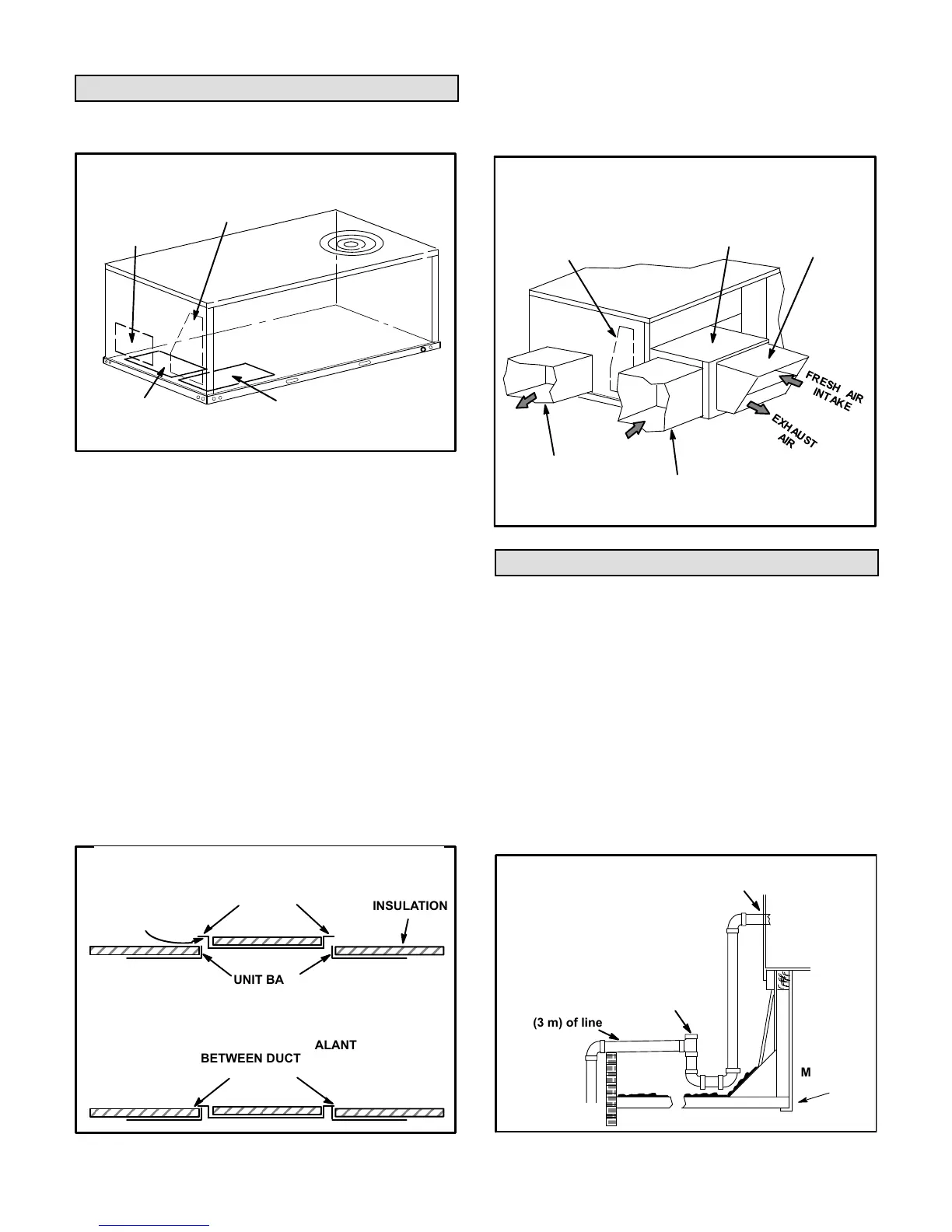

Horizontal Air Discharge

Unit is shipped with panels covering the horizontal supply

and return air openings. See figure 3.

FIGURE 3

DOWNFLOW

RETURN AIR

OPENING

UNIT SUPPLY AND RETURN AIR OPENINGS

DOWNFLOW

SUPPLY AIR

OPENING

HORIZONTAL

RETURN AIR

OPENING

HORIZONTAL

SUPPLY AIR

OPENING

1- Remove horizontal covers and place a bead of silicone

sealant on the underside of the duct cover flanges. See

figure 4.

2- Position covers over downflow openings. Secure

covers with self-drilling screws in at least two places on

each cover. Drill through duct cover side into flange of

base pan.

3- Place a bead of silicone between insulation and duct

cover to seal in insulation edges. Let silicone dry before

running gas or electric heat.

Units Equipped With An Optional Horizontal Economizer

1- Install the horizontal supply air cover over the down

flow supply air opening as described above.

2- Leave the horizontal return air cover in place.

3- Locate the extra horizontal return cover that is

included with the horizontal economizer kit. Install as

described in previous section.

FIGURE 4

INSTALL DUCT COVERS - SIDE VIEW

INSULATION

UNIT BASE

FLANGES

DUCT COVER

FLANGES

APPLY SILICONE

SEALANT TO

FLANGES

APPLY SILICONE SEALANT

BETWEEN DUCT COVER

FLANGE AND UNIT INSULATION

NOT TO

SCALE

4- Install return air duct on the intake air side of the

horizontal economizer. See figure 5.

5- Horizontal economizer and return air duct must be

field-supported.

This opening not used

in horizontal applica

tions with economizer

HORIZONTAL

RETURN AIR DUCT

(FIELD-PROVIDED)

UNIT

HORIZONTAL

SUPPLY AIR DUCT

(FIELD-PROVIDED)

OPTIONAL

HORIZONTAL

ECONOMIZER

HOOD

PROVIDED

WITH

ECONOMIZER

FIGURE 5

HORIZONTAL RETURN AIR DUCTWORK

WITH ECONOMIZER

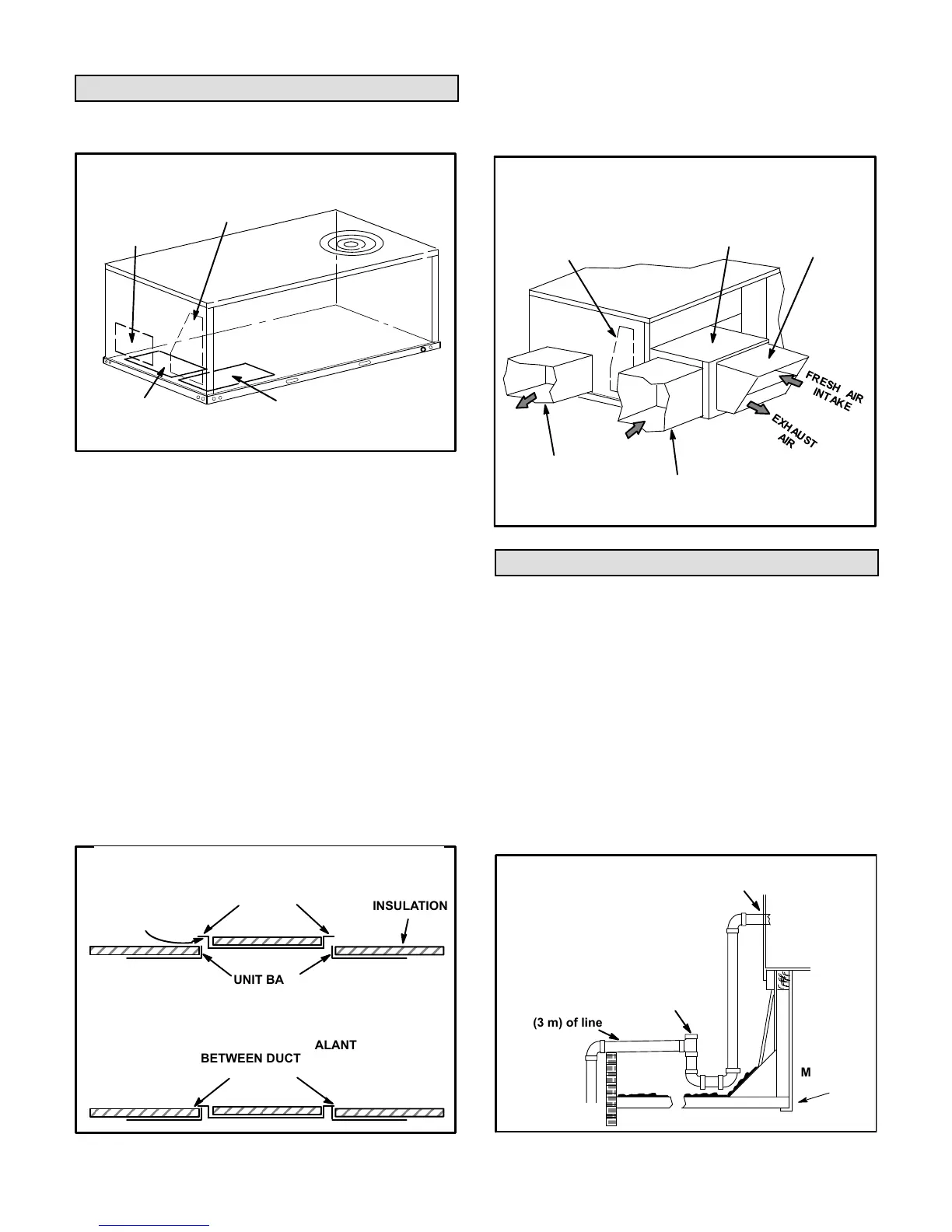

Condensate Drains

Make drain connection to the drain coupling provided

on unit.

Note - The drain pan is made with a glass reinforced

engineered plastic capable of withstanding typical joint

torque but can be damaged with excessive force. Tighten

pipe nipple hand tight and turn an additional quarter turn.

A trap must be installed between drain connection and an

open vent for proper condensate removal. See figure 6. It is

sometimes acceptable to drain condensate onto the roof or

grade; however, a tee should be fitted to the trap to direct

condensate downward. The condensate line must be

vented. Check local codes concerning condensate disposal.

Refer to pages 1 and 2 for condensate drain location.

FIGURE 6

UNIT

Minimum Pitch

1” (25 mm) per

10' (3 m) of line

MOUNTING

FRAME

OPEN VENT

CONDENSATE SIDE DRAIN CONNECTION

NOTE - Allow clearance to

open doors when installing

condensate piping.

CAULK AROUND CONDENSATE COUPLING

Loading...

Loading...