Function library

Positioning control

3.4.2 Machine parameters

3−27

l

EDSVS9332P−EXT DE 2.0

Application example

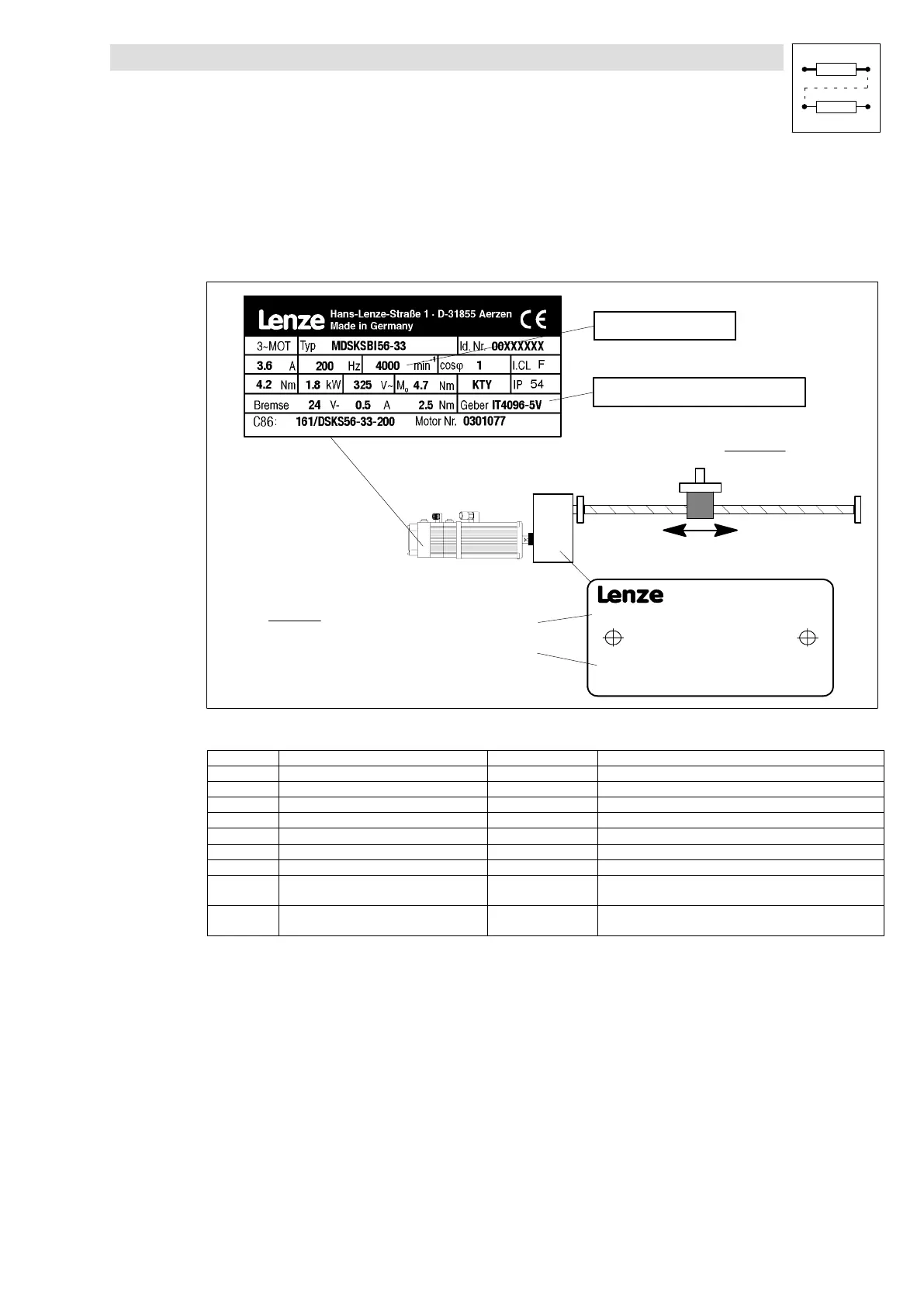

For positioning a spindle feeding unit is driven via a gearbox. Instead of the standard resolver an

incremental encoder is used as feedback system. The incremental encoder is mounted to the motor

and has a number of increments of 4096 pulses / rev.. The gearbox has a ratio of i = 32 (n

motor

/n

spindle

).

The spindle has a lead of h=10mm. The entries are to be made in mm (1 mm = 1 unit).

EXTERTAL/Germany

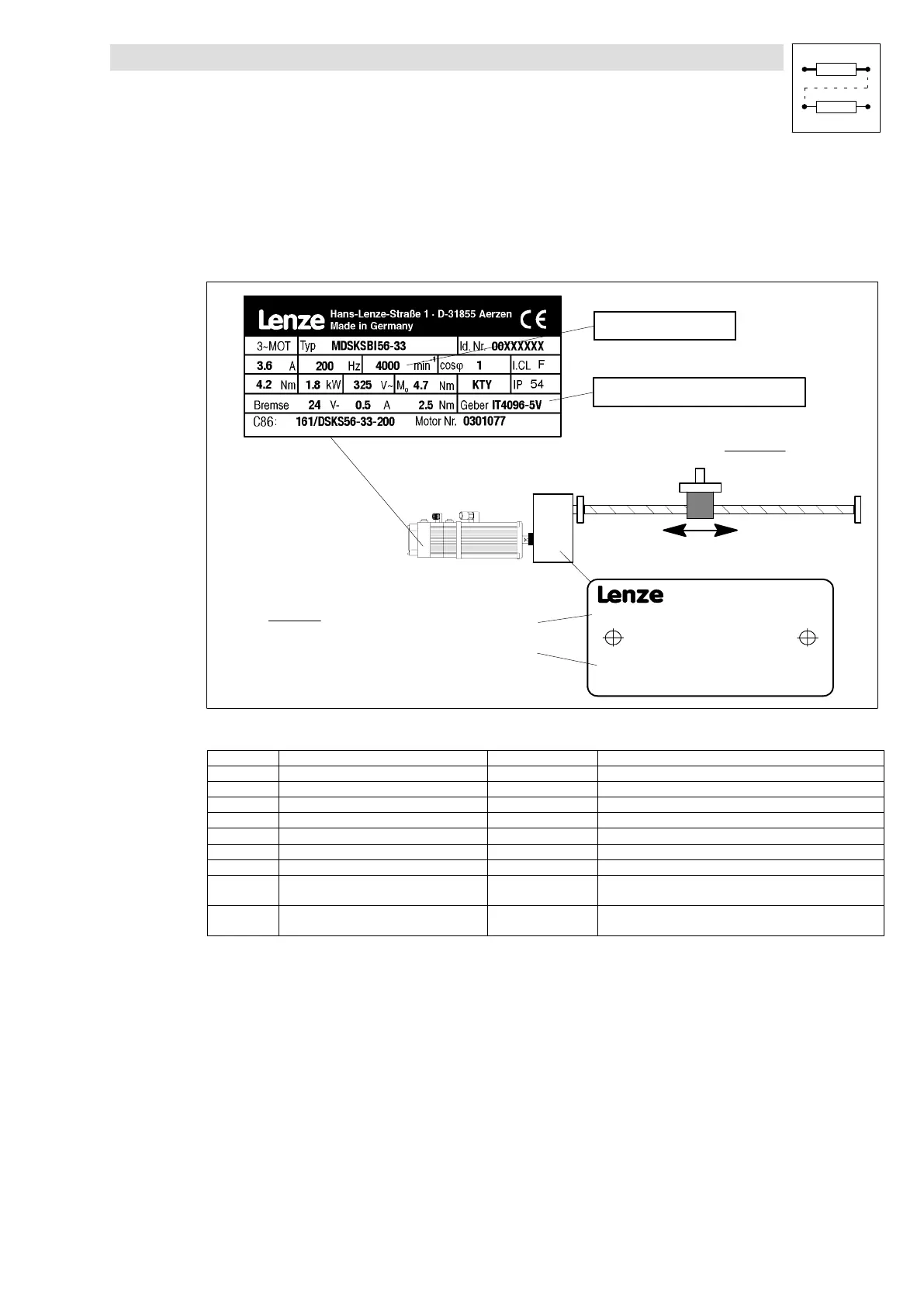

GFL05−2 M HCR 080−32

295 Nm

24 /min (50 Hz)

i=58.667

CLP460 1196

GT/40000027

004 B

00500038

i +

(

z2 @ z4

)

(

z1 @ z3

)

+ 58, 667

z1 = 12

z2 = 88

z3 = 9

z4 = 72

C1202 + z2 @ z4 + 6336

C1203 + z1 @ z3 + 108

C1204 + 5.023

mm

Umdrehung

C0011 + 4000 min

*1

C0025ń113 + EncTTL, 4096inc,5V

Settings:

Code Designation Entry Notes

C0025 Encoder system selection −113− Incremental encoder, IT−4096−5V

C0420 Encoder constant X8 4096 incr (automatically through C0025)

C0490 Position feedback system −1− (TTL encoder) (automatically through C0025)

C0495 Speed feedback system −1− (TTL encoder) (automatically through C0025)

C1202 Gearbox numerator 6336 Numerator corresponds to motor speed

C1203 Gearbox denominator 108 Denominator corresponds to gearbox output speed

C1204 Feed constant 5.023 units/rev mm per rev. at gearbox output

C1207/1 Position encoder gearbox factor, numerator 1 (1/1 = no gearbox between encoder and motor)

Numerator corresponds to motor speed

C1207/2 Position encoder gearbox factor,

denominator

1 (1/1 = no gearbox between encoder and motor)

Denominator corresponds to encoder speed

Loading...

Loading...