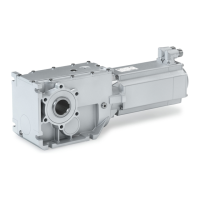

Gearbox with hollow sha and shrink disc

NOTICE

▶

Never disassemble the new shrink disc.

▶

Thoroughly clean and degrease hollow sha bore and machine sha!

▶

Do not ghten clamping screws before the machine sha has been inserted, the hollow

sha may undergo plasc deformaon.

▶

Cover the shrink disc during operaon so that it is secured against contact by implemenng

suitable measures (e.g. cover).

Mounng the machine sha

1 Rotang cover

2 Clamping screws

1.

Check machine sha

-

Diameter in t tolerance h6

-

Material yield point Re ≥= 360 MPa

-

E-module approx. 210000 MPa

-

Surface roughness R

z

≤ 15 µm

-

Concentricity (to prevent unnecessary addional forces caused by tensioning)

2. Remove rotang cover (1) from the shrink disc

3.

Thoroughly clean and degrease hollow sha bore and machine sha.

4.

Slightly loosen clamping screws (2) one aer the other, do not unscrew.

5.

Push gearbox onto machine sha.

6.

Slightly ghten clamping screws manually.

7.

Tighten clamping screws (2) one aer the other (approx. 5) in several passes, with rising

torque, evenly unl the indicated screw-ghtening torque is reached at all screws.

8.

Pull the co-rotang cover (1) over the shrink disc.

Mechanical installaon

Mounng

28

Loading...

Loading...