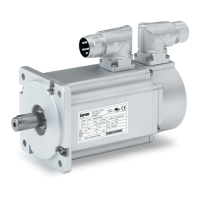

Motor connecon

Connecon via terminal box

Observe the notes on wiring, data on the nameplate, and the connecon diagram in the

terminal box.

The connecon must ensure a connuous and safe electrical supply:

•

No protruding wire ends

•

Use assigned cable end ngs

•

Ensure good electrical conducvity of the contact (remove paint residues) if an addional

PE connecon is used

•

Establish a safe protecve earth connecon

•

Aer the connecon is completed, make sure that all connecons on the terminal board

are rmly ghtened

•

The terminal box has to be free of foreign bodies, dirt, and humidity

•

All unused cable entries and the terminal box itself must be sealed so that they are dust-

ght and waterproof

The smallest air gaps between uncoated, live parts and against earth must not fall below the

following values:

Minimum requirements for basic insulaon

according to IEC/EN 60664-1 (CE)

Higher requirements for UL design Motor diameter

3.87 mm 6.4 mm <178 mm

9.5 mm > 178 mm

Cable glands

The bore holes for the cable glands M25, M20 and M32 are located on both

sides and closed. They can be opened according to need.

Motor MCS09 MCS14L15 MCS14L32

MCS12 MCS14P14 MCS14P32

MCS14H MCS19F15 MCS19F13

MCS19J15 MCS19J30

MCS19P

Screwed connecons 2x M20

2x M25

2x M32

cable cross-secon

mm

2

0.08 ... 2.5

4 (without wire end ferrule)

0.2 ... 10

Stripping length mm 10 ... 11

Terminal design Spring-loaded terminal

Electrical installaon

Motor connecon

Connecon via terminal box

22

Loading...

Loading...