Lewmar OCEAN & EVO® Electric/Hydraulic Winches ref B2303 Iss.14 | 11

4.1 Electric cable selection

The cable table gives recommended cable sizes based

on total length of cable required, from the battery, fol-

lowing the route of the cables. Lewmar recommends to

source and install cable that meets the requirements of

the standards and regulations relevant to the installa-

tion and codes of practice.

• Winch performance is directly related to cable

size and length. The cable sizes are calculated

so that the maximum overall voltage drop do not

exceed10% over the whole cable installation.

4.2 Wiring

Plan the installation to suit the controls and give the operator a full view of the winch. The wiring system should

be of the fully insulated type, which avoids possible electrolytic corrosion problems. We recommend the use of

type III stranded, tinned copper wire with copper crimp terminals. Most modern installations are negative return

(negative ground) but polarity should be checked.

Overload protection, in the form of the circuit breaker/fuse (not supplied), must be built into the winch wiring

circuit.

NOTE: The circuit breaker should be positioned close to the battery in a dry, readily accessible place.

• The breaker must be manually reset should an overload occur that causes it to trip to the off position.

• If you are not sure you understand these guidelines, seek professional help. Ensure that the installation

complies with USCG, ABYC, NMMA or other local regulations.

4.3 Control switch installation

Follow the mounting instructions supplied with the switch.

DO NOT confuse cable Length

with the length of the vessel!

4. Electrical Wiring

WARNING!

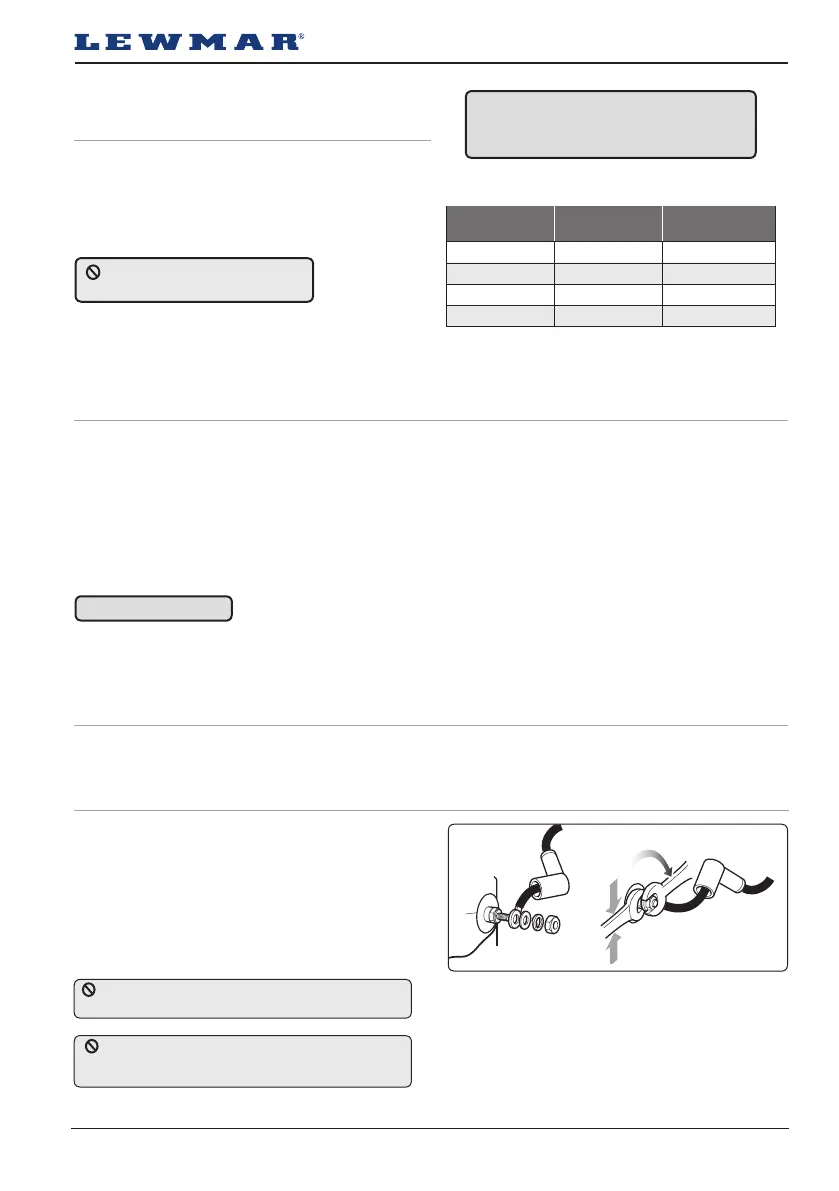

CABLE SIZE

12V DC

CABLE SIZE

24V DC

TOTAL CABLE

DISTANCE

50 mm2 (1/0 AWG) 25 mm2 (3 AWG) up to 7 m (23 ft)

70 mm2 (2/0 AWG) 35 mm2 (2 AWG) 7-10 m (23-33 ft)

70 mm2 (2/0 AWG) 50 mm2 (1/0 AWG) 10-15 m (33-49 ft)

95 mm2 (3/0 AWG) - 15-20 m (49-66 ft)

WARNING! All electrical work must be

carried out with the power OFF. Isolate

the winch using circuit breaker/isolator.

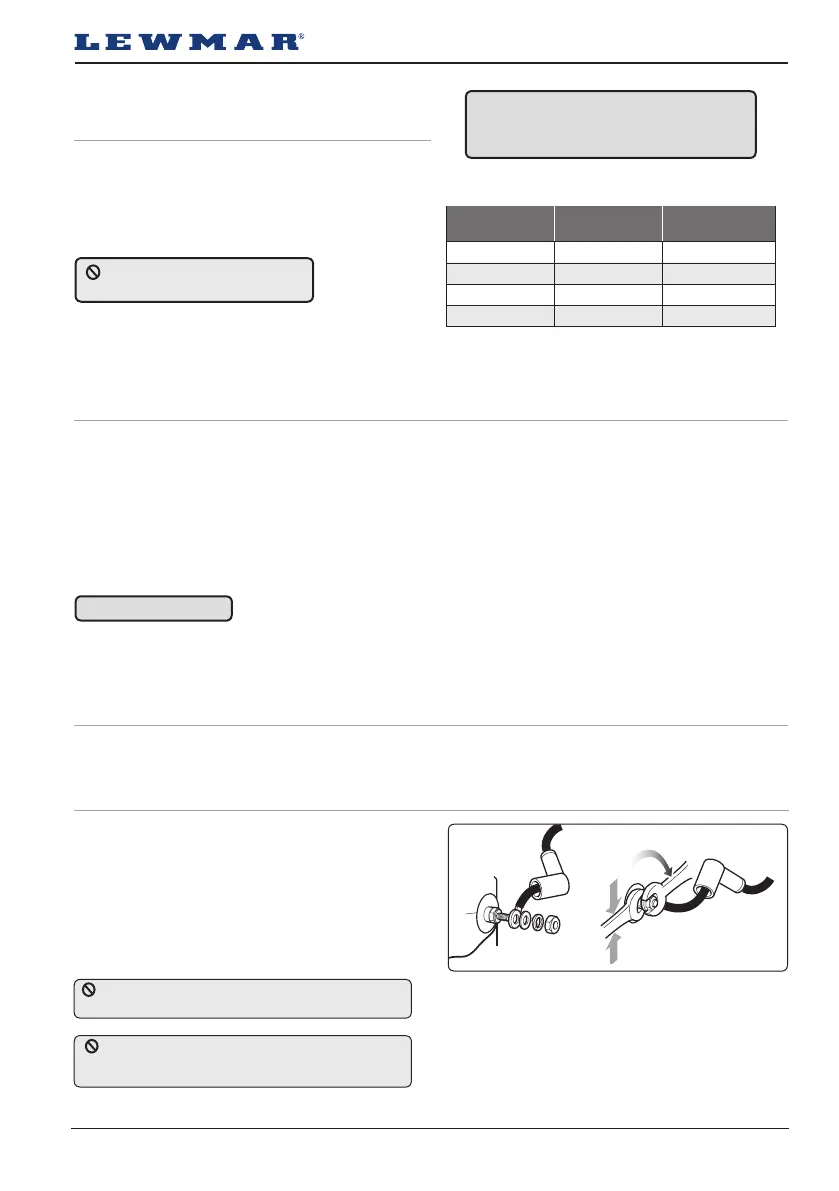

When wiring Lewmar electric motor into the ship’s

electrical system the following caution must be

taken.

When tightening the front nut hold the back nut with

a separate wrench to make sure the back nut does

not turn. If the back nut turns, serious damage will

occur, voiding Lewmar’s warranty on the electric

motor.

4.4 Electric motor terminal connections

DO NOT over tighten electric motor

terminal nuts.

Tighten M8 front nut to a torque setting of

15Nm to 18Nm

Loading...

Loading...