7.3.2 Pumping of condensable gases and vapours

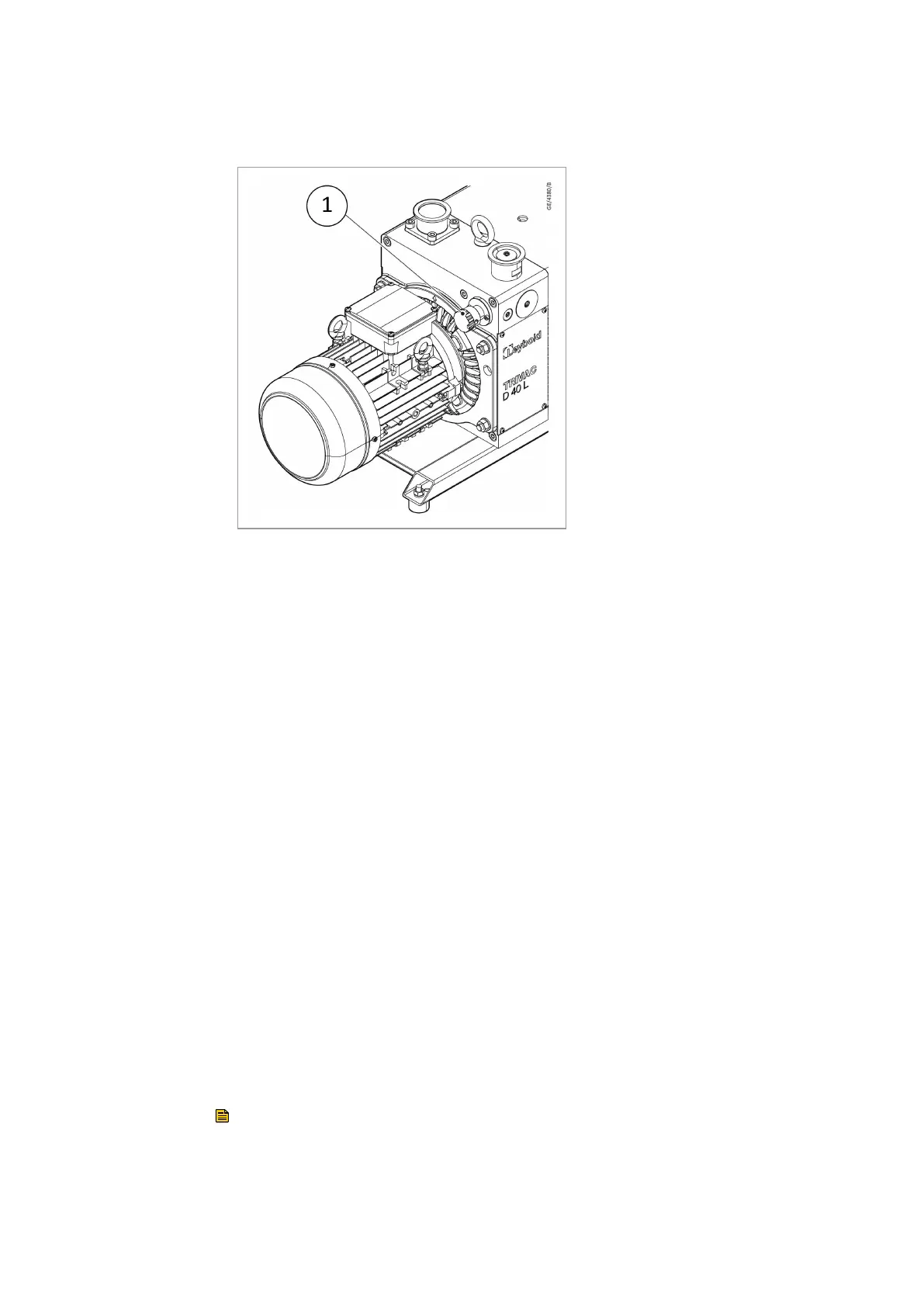

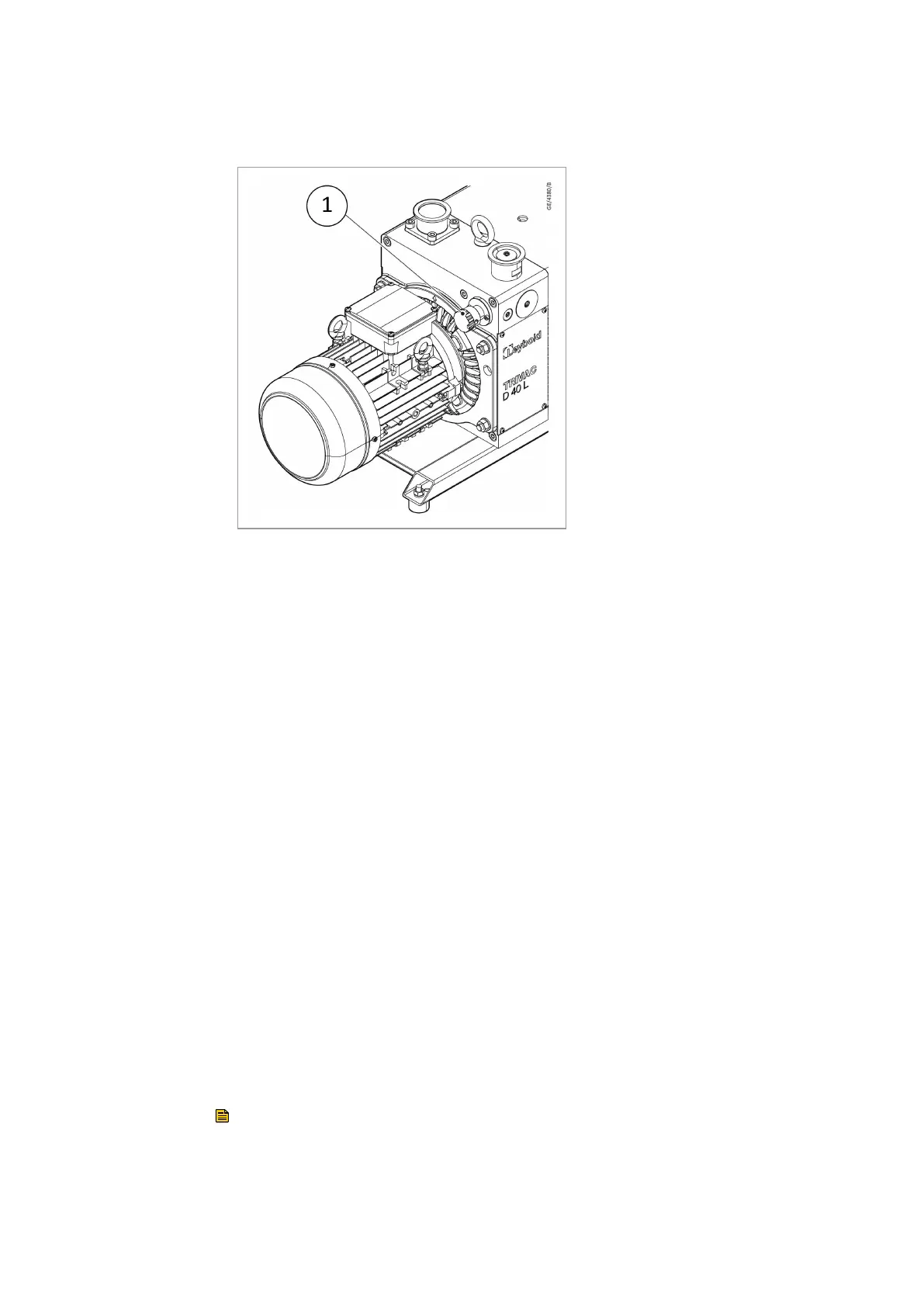

1. Gas ballast valve1. Gas ballast valve

The pump is equipped with a three-position manual gas ballast valve which

operates with air.

The gas ballast is operated manually by turning the rubber knob on the gas

ballast head. There are 3 positions:

▪ 0 - closed (to achieve best ultimate pr

essure)

▪ I - standard ow for standard vapour load

▪ II - high ow for high vapour load (hydro mode)

The gas ballast

ow is valid for a pump operating at ultimate pressure (inlet

closed) and for a gas ballast gas supply of 1 bar (absolute). Above

1 bar (absolute) the pump may get damaged.

To operate the gas ballast with inert gas, remove the standard gas ballast

and install the 'permanent gas ballast kits' with DN 16 KF connection

available as an accessory. Refer to Accessories on page 58. For remote

control, t an EM gas ballast valve kit (available as an accessory, refer to

Accessories on page 58). The EM gas ballast valve must be supplied with

24 V d.c.

The pump is slightly louder if the gas ballast valve is open. With the gas

ballast valve open (position I or II) and when the temperature is stabilised,

the pump can pump pure water vapour up to the water vapour tolerance

specied in the technical data. If the vapour pressure increases above the

permissible level, the water vapour will condense in the oil of the pump.

When pumping vapours make sure that the gas ballast valve is open and

that the pump has been warmed up for approximately 30 minutes with the

intake line closed.

Note:

Vapour phases may only be pumped up to the permissible limit after the

pump has attained its operating temperature.

300956027_002_A0 - 03/2022 - © Leybold

36

Operation

Loading...

Loading...