89

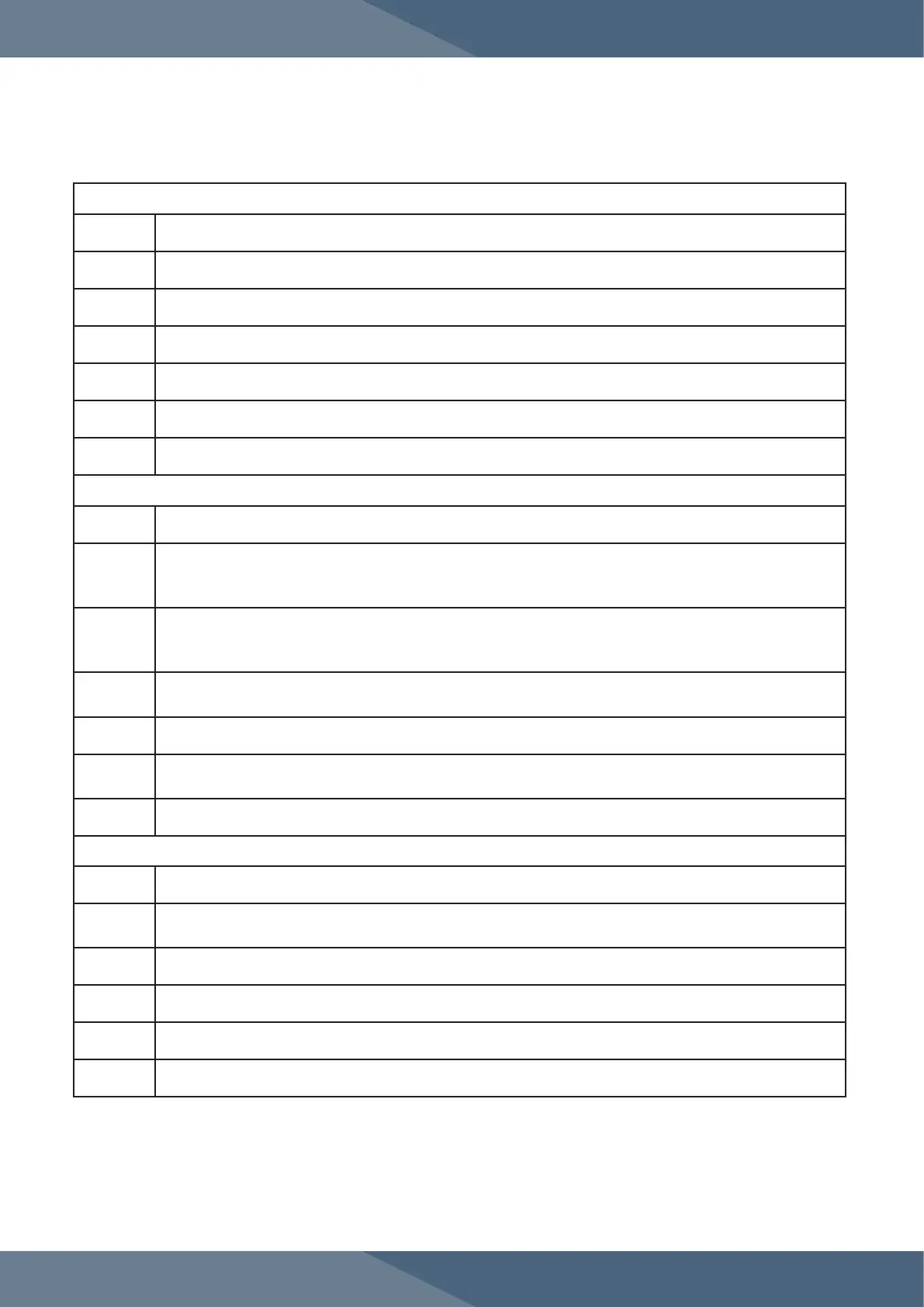

Maintenance Checklist

Before Operation

□

Visually inspect the tablet press and the parts.

□

Ensure all locking nuts are tight.

□

Visually inspect Grease Nipples and regrease where necessary.

□

Manually rotate the machine without powders to ensure that it is not jammed

□

Ensure Handle is removed from the Drive Belt Pulley socket.

□

Ensure Perspex Casing securely encloses the upper portion of machine.

□

Visually inspect electrical wires for any damage.

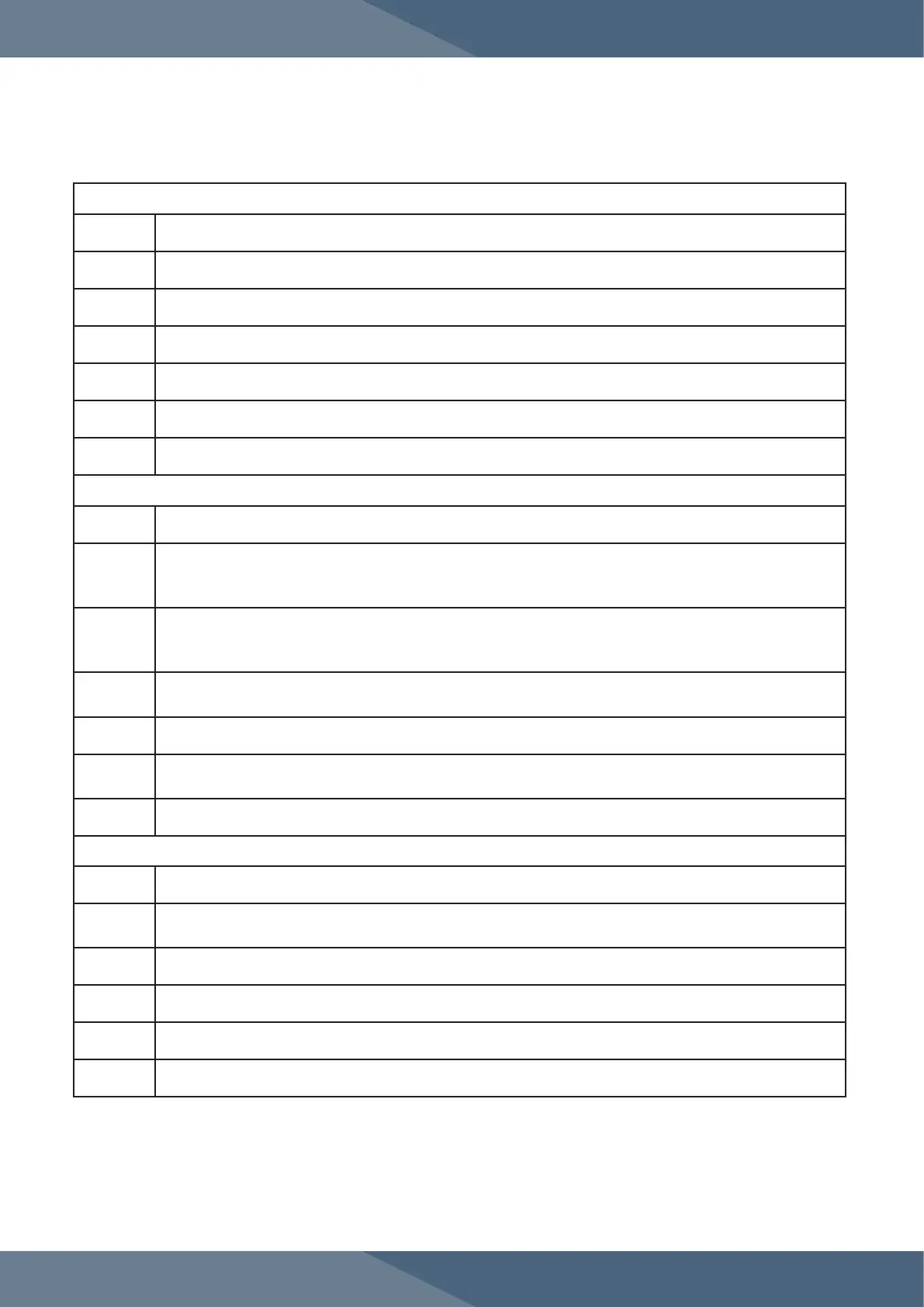

During Operation

□

Tune the tablet press until the tablet size and weight are correct

□

Listen for irregular knocking or clicking sounds. If heard, stop operation, release the

pressure by rotating the Pressure Knob on the lefthand side of the machine clockwise a

few times, and lubricate the machine.

□

Watch for buildup of powder in front of the Fill Tray. If occurring, either (a) make mix more

granular, (b) check the Fill Tray for damage, (c) clear the buildup, or (d) adjust the Fill Tray

and/or Hopper.

□

Occassionally check the Motor's temperature. If it starts to overheat, turn off the machine,

let it cool down, and grease it to ensure smooth operation.

□

Ensure that the Hopper does not run out of powder.

□

Weigh five or ten sample tablets to ensure the desired weights, tablet height, and hardness

are being met.

□

Check to see that the Emergency Stop properly works.

After Operation

□

Unplug machine and remove all excess powder with a bagless vacuum.

□

Remove the Perspex Casing, Hopper, Fill Tray, Tooling, Upper Roller Cam Housing, and

Turret and clean the inside of the tablet press.

□

Wipe down the other surfaces with a damp cloth.

□

Apply a layer of NSF approved grease to the entire tablet press.

□

Lubricate all Grease Nipples.

□

Store Tooling in an air-tight box with a small amount of grease.

Loading...

Loading...