- 11 -

LGE Internal Use Only

Copyright © LG Electronics. Inc. All right reserved.

Only for training and service purposes

4. Total Assembly line process

4.1. White Balance adjustment

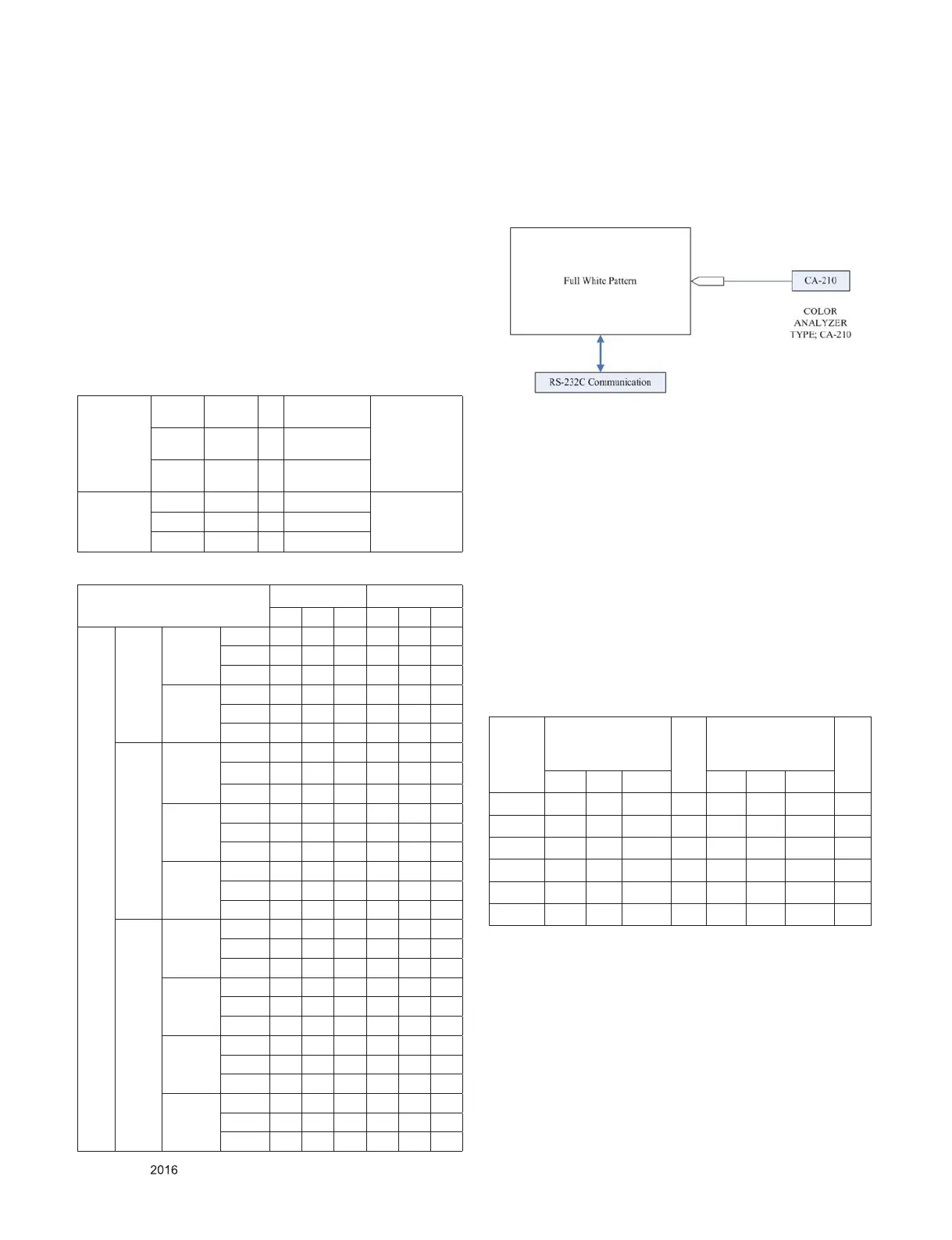

1) Color Analyzer: CA-210 (LED Module : CH 14)

2) Adj. Computer(During auto adj., RS-232C protocol is

needed)

3) Service Remote control

* RGB Gains are xed data for each model. Insert RS-232C

Jack which is connected with PC for White Balance or

equivalent device.

→ Total Assembly line should be check whether the color

coordinate(x,y) data refer to below table were meet or

not. Color coordinate is differ from panel’s characteristics

of color temperature. Please check panel characteristics

about color temperature.

- Cool Panel

▪ White Balance Default value

* Connecting picture of the measuring instrument (On Auto-

matic control)

- Inside PATTERN is used when W/B is controlled. Con-

nect to auto controller or push Adjustment R/C POWER-

ON → Enter the mode of White-Balance, the pattern will

come out.

* Auto-control interface and directions

1) Adjust in the place where the inux of light like oodlight

around is blocked. (Illumination is less than 100Lux).

2) Adhere closely the Color Analyzer ( CA210 ) to the

module less than 10cm distance, keep it with the surface

of the Module and Color Analyzer’s Prove vertically.

(80~100°).

3) Aging time

- After aging start, keep the power on (no suspension of

power supply) and heat-run over 5 minutes.

- Using ‘no signal’ or ‘full white pattern’ or the others,

check the back light on.

* Auto adjustment Map(using RS-232C to USB cable)

RS-232C COMMAND

[ CMD ID DATA ]

Wb 00 00 White Balance Start

Wb 00 ff White Balance End

RS-232C

COMMAND

[CMD ID DATA]

M

I

N

CENTER

(DEFAULT)

M

A

X

Cool Mid Warm Cool Mid Warm

R Gain jg Ja jd 00 172 192 192 254

G Gain jh Jb je 00 172 192 192 192

B Gain ji Jc jf 00 192 192 172 254

R Cut 64 64 64 128

G Cut 64 64 64 128

B Cut 64 64 64 128

**Caution

- Color Temperature : COOL, Medium, Warm.

- One of R Gain/G Gain/ B Gain should be kept on 0xC0, and

adjust other two lower than C0.

( when R/G/B Gain ar e all C0, it is the FULL Dynamic Range

of Module)

Color

Temperature

Cool 13,000 °K X=0.276 (±0.04)

Y=0.275 (±0.04)

<Test Signal>

Inner pattern

(204gray,80IRE)

Medium 9,300 °K X=0.290 (±0.04)

Y=0.298 (±0.04)

Warm 6,500 °K X=0.318 (±0.04)

Y=0.334 (±0.04)

Luminance

(cd/m²)

Cool Min : 80 Typ : 110 <Test Signal>

Inner pattern

(204gray,80IRE)

Medium Min : 70 Typ : 110

Warm Min : 80 Typ : 110

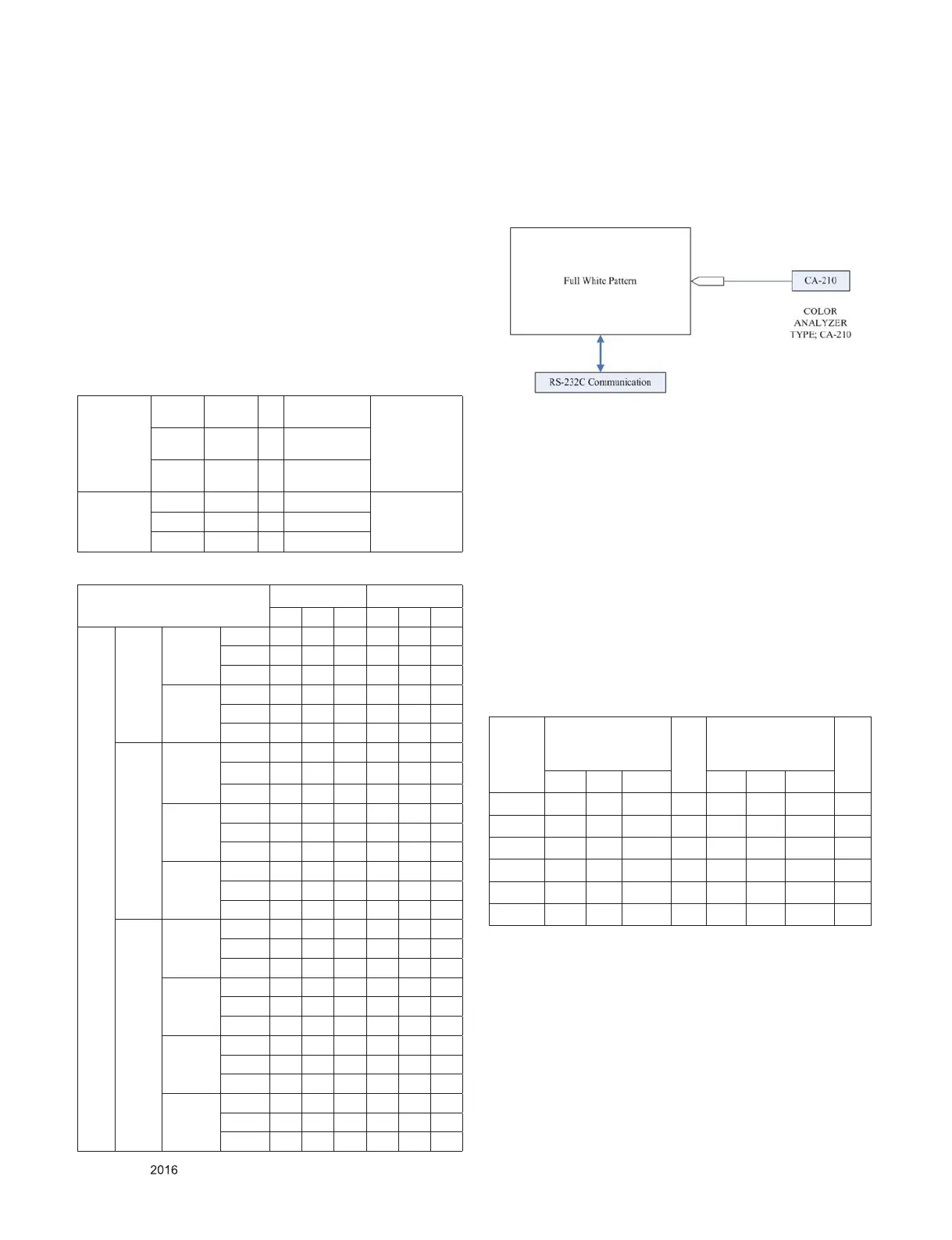

Model Gain Cut

R G B R G B

MT41 22 MT41 LGD

(AH-IPS/

FHD)

Cool 125 130 192 64 64 64

Medium 161 170 210 64 64 64

Warm 185 185 192 64 64 64

Heesung

(AH-IPS /

FHD)

Cool 121 126 192 64 64 64

Medium 165 172 210 64 64 64

Warm 186 185 192 64 64 64

24MT41 CMI

(VA / HD)

Cool 178 172 213 64 64 64

Medium 171 185 196 64 64 64

Warm 192 185 144 64 64 64

LGD

(AH-IPS/

HD)

Cool 180 172 216 64 64 64

Medium 192 172 185 64 64 64

Warm 192 154 120 64 64 64

BOE

(VA / HD)

Cool 192 182 208 64 64 64

Medium 192 175 170 64 64 64

Warm 192 168 104 64 64 64

28MT41 Heesung

BM

CSOT

(VA / HD)

Cool 179 172 208 64 64 64

Medium 192 180 177 64 64 64

Warm 192 167 110 64 64 64

Heesung

BM

BOE

(VA / HD)

Cool 182 172 222 70 70 70

Medium 192 173 192 70 70 70

Warm 192 168 130 70 70 70

Chilin BM

BOE

(VA / HD)

Cool 192 170 204 70 70 70

Medium 192 157 163 70 70 70

Warm 192 146 102 70 70 70

Heesung

BM VI

BOE

(VA / HD)

Cool 192 170 204 70 70 70

Medium 192 157 163 70 70 70

Warm 192 146 102 70 70 70

Loading...

Loading...