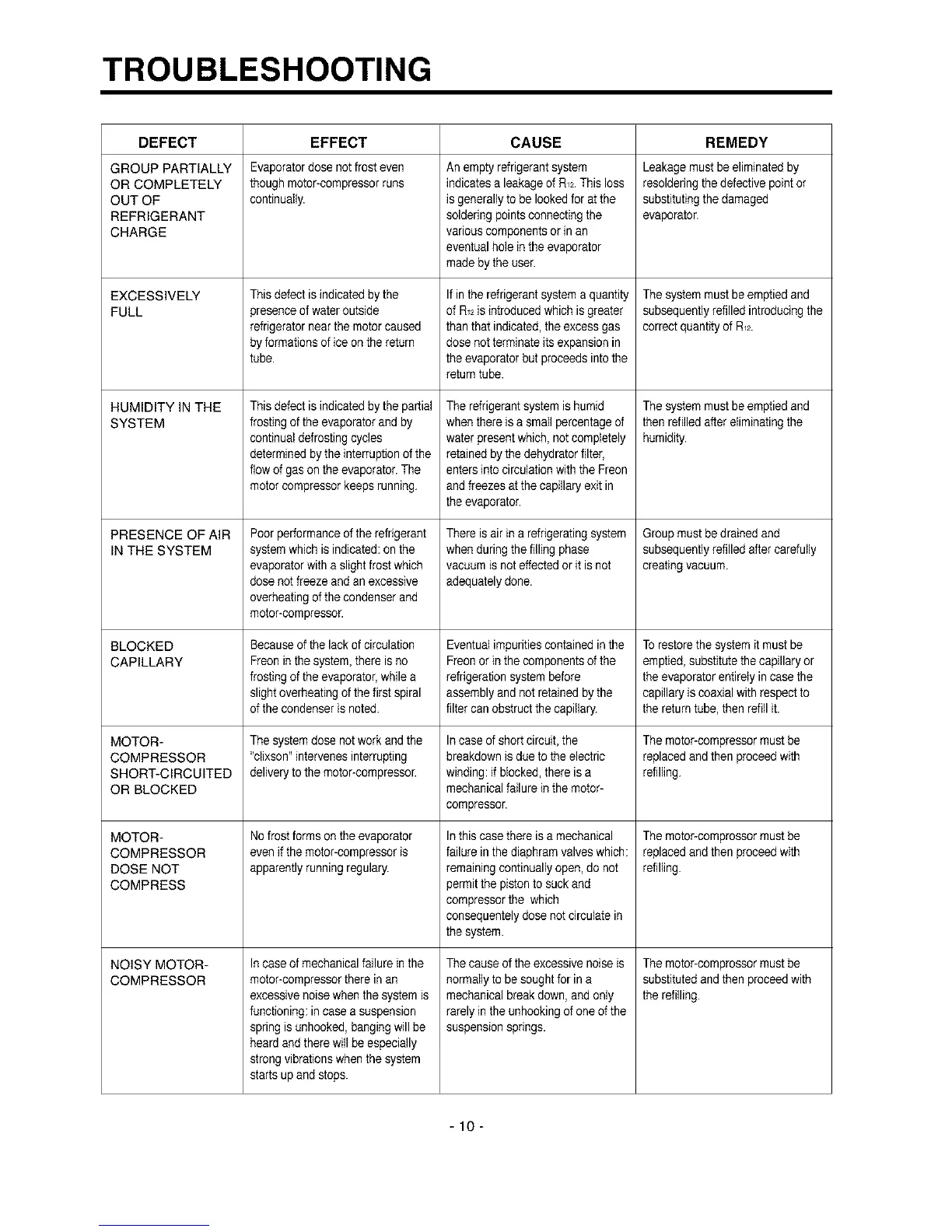

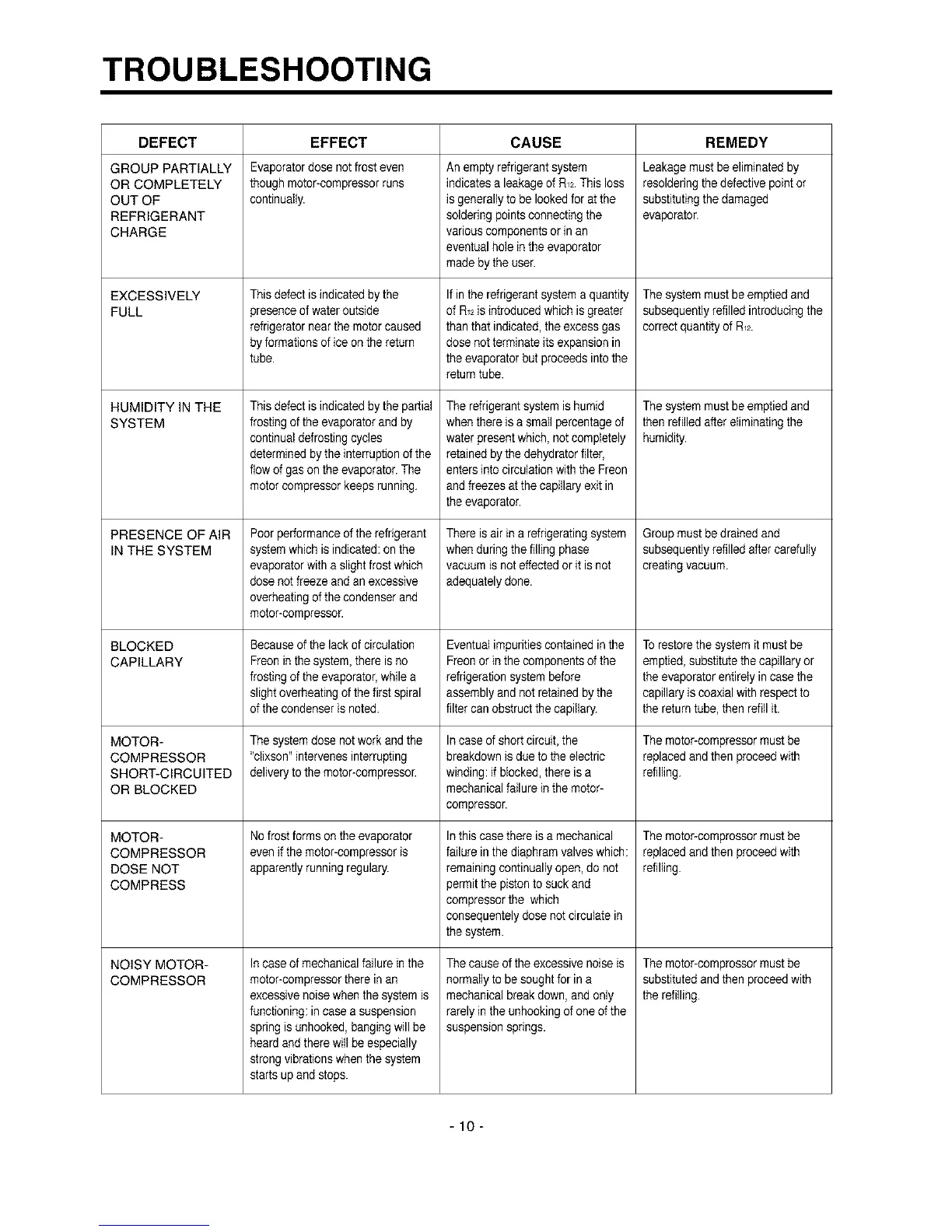

TROUBLESHOOTING

DEFECT CAUSE REMEDY

GROUP PARTIALLY

OR COMPLETELY

OUT OF

REFRIGERANT

CHARGE

EXCESSIVELY

FULL

HUMIDITY IN THE

SYSTEM

PRESENCE OFAIR

IN THE SYSTEM

BLOCKED

CAPILLARY

MOTOR-

COMPRESSOR

SHOR%CIRCUITED

OR BLOCKED

MOTOR-

COMPRESSOR

DOSE NOT

COMPRESS

NOISY MOTOR-

COMPRESSOR

EFFECT

Evaporatordose notfrosteven

though motor-compressorruns

continually.

This defectis indicatedby the

presenceof wateroutside

refrigeratornearthe motor caused

by formationsof ice onthe return

tube.

This defectis indicatedby the partial

frostingof the evaporatorand by

continualdefrostingcycles

determinedby the interruptionofthe

flow of gas onthe evaporator.The

motor compressorkeeps running.

Poorperformanceof the refrigerant

system which is indicated:onthe

evaporatorwith a slightfrostwhich

dose not freezeand an excessive

overheatingof the condenserand

motor-compressor.

Becauseof the lackof circulation

Freoninthe system,thereis no

frostingof the evaporator,while a

slightoverheatingofthe first spiral

of the condenseris noted.

Thesystem dose notwork andthe

"clixson"intervenesinterrupting

deliveryto the motor-compressor.

Nofrost formson the evaporator

even if the motor-compressoris

apparentlyrunning regulary.

Incaseof mechanicalfailurein the

motor-compressorthere in an

excessivenoisewhen the systemis

functioning:in casea suspension

springis unhooked,bangingwill be

heard and therewill be especially

strong vibrationswhen the system

starts up and stops.

An emptyrefrigerantsystem

indicates a leakageof R_2.This loss

is generallyto be lookedfor at the

soldering pointsconnectingthe

variouscomponentsor in an

eventualhole in the evaporator

made bythe user.

If in the refrigerantsystema quantity

of R_2is introducedwhich is greater

than that indicated,the excessgas

dose net terminateits expansionin

the evaporatorbut proceedsintothe

returntube.

The refrigerantsystemis humid

when thereis a small percentageof

water presentwhich, notcompletely

retainedby the dehydratorfilter,

enters intocirculationwiththe Freen

and freezes atthe capillaryexit in

the evaporator.

There isair in a refrigeratingsystem

when duringthe filling phase

vacuum isnot effectedor it is not

adequatelydone.

Eventualimpuritiescontainedinthe

Freonor in the componentsof the

refrigerationsystem before

assemblyand not retainedbythe

filter canobstruct the capillary.

Incaseof shortcircuit,the

breakdownis dueto the electric

winding: if blocked,there isa

mechanicalfailurein the motor-

compressor.

Inthiscasethere is a mechanical

failure inthe diaphramvalves which:

remainingcontinuallyopen, do not

permit the pistonto suckand

compressorthe which

consequentelydose notcirculate in

the system.

The causeof the excessivenoiseis

normallyto be soughtfor in a

mechanical breakdown, and only

rarely in the unhookingof one of the

suspensionsprings.

Leakagemust be eliminatedby

resolderingthedefectivepoint or

substitutingthe damaged

evaporator.

Thesystemmust be emptiedand

subsequentlyrefilledintroducingthe

correctquantityof R_2.

Thesystemmust be emptiedand

then refilledafter eliminatingthe

humidity.

Groupmust bedrained and

subsequentlyrefilledaftercarefully

creatingvacuum.

Torestorethe systemit must be

emptied,substitutethe capillaryor

theevaporatorentirelyin casethe

capillaryis coaxialwith respectto

the returntube, then refillit.

Themotor-compressormust be

replacedand then proceedwith

refilling.

Themotor-compressormust be

replacedand then proceedwith

refilling.

Themotor-comprossormust be

substitutedand then proceedwith

the refilling.

-10-

Loading...

Loading...