47

Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

REFRIGERANT PIPING

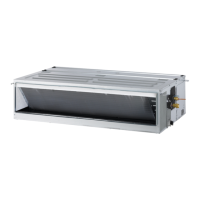

Figure 34: Using Nitrogen Gas During Brazing

Refrigerant Safety

ASHRAE Standards 15-2010 and 34-2010 offer guidelines that address refrigerant safety and the maximum allowable concentration of

refrigerant in an occupied space. Refrigerant will dissipate into the atmosphere, but a certain volume of air is required for this to occur safely.

For R410A refrigerant, the maximum allowable concentration of refrigerant is twenty-six (26) lbs. per 1,000 cubic feet of an occupied space.

Buildings with twenty-four (24) hour occupancy allow half of that concentration.

1

ASHRAE Standards 15 and 34 assume that if a system develops a leak, its entire refrigerant charge will dump into the area where the leak

occurs. To meet ASHRAE Standards 15 and 34, calculate the refrigerant concentration that may occur in the smallest room volume on the

system, and compare the results to the maximum allowable concentration number.

1

Also consult state and local codes in regards to

refrigerant safety.

Verify the maximum refrigerant concentration level in the space where the indoor unit will be mounted meets the concentration limit for the application.

There is risk of asphyxiation from oxygen depletion.

1

Information about ASHRAE Standard 15-2010/34-2010 and addenda current as of the date of this publication.

Auxiliary

Valve

Tape

(no air bubbles)

Do not block outlet side.

When pressure inside pipe

is above atmospheric pressure,

pinhole leaks can occur.

Refrigerant Pipe

Welding Point

Regulator

Nitrogen gas

3.0 psi or less

Nitrogen

Gas

Tank

Brazing

Note:

It is imperative to keep the piping system free of contaminants and debris such as copper burrs, slag, or carbon dust during installation.

1. All joints are brazed in the field. Multi V refrigeration system components contain very small capillary tubes, small orifices, electronic

expansion valves, oil separators, and heat exchangers that can easily become blocked. Proper system operation depends on the

installer using best practices and utmost care while assembling the piping system.

• Store pipe stock in a dry place and keep stored pipe capped and clean.

• Purge all pipe sections clean with dry nitrogen prior to assembly.

2. Proper system operation depends on the installer using best practices and the utmost care while assembling the piping system.

• Use adapters to assemble different sizes of pipe.

• Always use a non-oxidizing material for brazing. Do not use ux, soft solder, or anti-oxidant agents. If the proper material is not used, oxi-

dized lm may accumulate and clog or damage the compressors. Flux can harm the copper piping or refrigerant oil.

• Use a tubing cutter; do not use a saw to cut pipe. De-bur and clean all cuts before assembly.

3. Brazing joints:

• Use a dry nitrogen purge operating at a maximum pressure of three (3) psig and maintain a steady ow.

• Use a 15% silver phosphorous copper brazing alloy to avoid overheating and produce good ow.

• Protect isolation valves, electronic expansion valves, and other heat-sensitive control components from excessive heat with a wet rag or

heat barrier spray.

Loading...

Loading...