62 | ELECTRICAL CONNECTIONS

MULTI V Water 5 Water Source Unit Engineering Manual

Due to our policy of continuous product innovation, some specications may change without notication.

© LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG ” is a registered trademark of LG Corp.

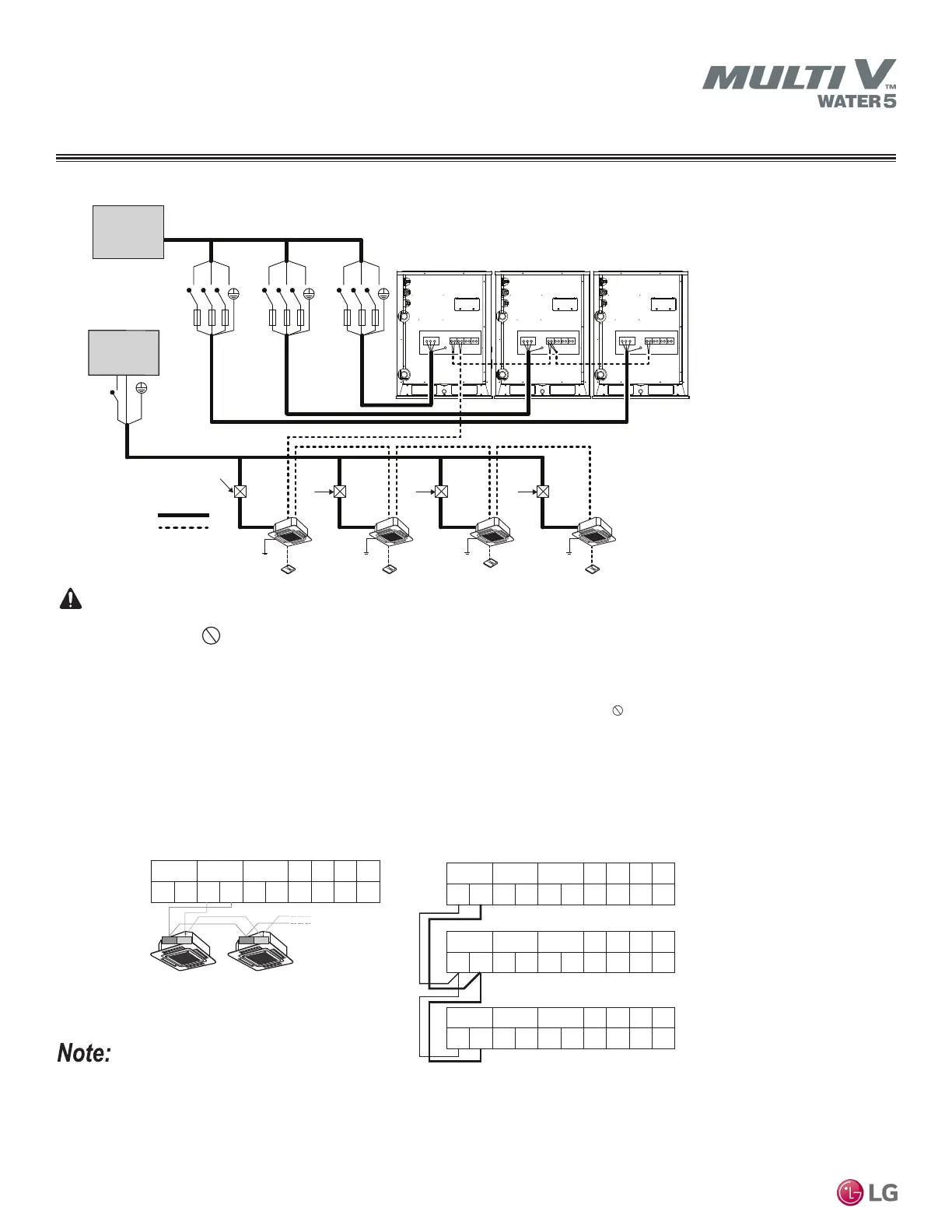

Figure 8: Example of a Typical Heat Pump Operation Power Wiring and Communications Cable Schematic.

SYSTEM FOR HEAT PUMP

OPERATION, 208-230V AND 460V

• Ground wiring is required to prevent accidental electrical shock during current leakage, communication problems from electrical noise, and

motor current leakage. Do not connect the ground line to the pipes. There is risk of re, electric shock, explosion, physical injury or death.

• Install a main shutoff switch that interrupts all power sources simultaneously. There is risk of fire, electric shock, explosion, physical injury

or death.

• Communication cable between Main ODU to Sub ODU(s), and Main ODU to IDUs to be 18 AWG, 2-conductor, twisted, stranded, shielded.

Ensure the communication cable shield is properly grounded to the Main ODU chassis only. Do not ground the ODU to IDUs

communication cable at any other point. Wiring must comply with all applicable local and national codes. Inadequate connections may

generate heat, cause a fire, and physical injury or death.

• The GND terminal at the main PCB is a negative terminal for dry contact, not a ground. Inadequate connections may generate heat, cause

a fire, and physical injury or death.

• Make sure that the terminal numbers of main water source unit and sub water source unit(s) match (A to A, B to B). The system will

malfunction if not properly wired.

• Maintain polarity throughout the communication network. The system will malfunction if not properly wired.

• If the system operates in reversed phase, it may break the compressors and other components.

• If there is a possibility of reversed phase, phase loss, momentary blackout, or the power goes on and off while the system is operating, install

a eld-supplied phase loss protection circuit. Operating the system in reverse phase may break the compressor and other unit components.

Main WSU

Indoor Units

Main Switch

Sub WSU Sub WSU

Pull Box

(Installer option)

R

(L1)

Switch

Switch

Switch

Fused

Disconnect

S

(L2)

T

(L3)

R

(L1)

S

(L2)

T

(L3)

R

(L1)

S

(L2)

T

(L3)

Power Supply

3 Phase, 60Hz

208/230V

or 460V

Power Supply

1 Phase, 60Hz

208/230V

Pull Box

(Installer

option)

Pull Box

(Installer

option)

Pull Box

(Installer

option)

Power Cable:

Communication Cable:

Fused

Disconnect

Fused

Disconnect

L1

L2

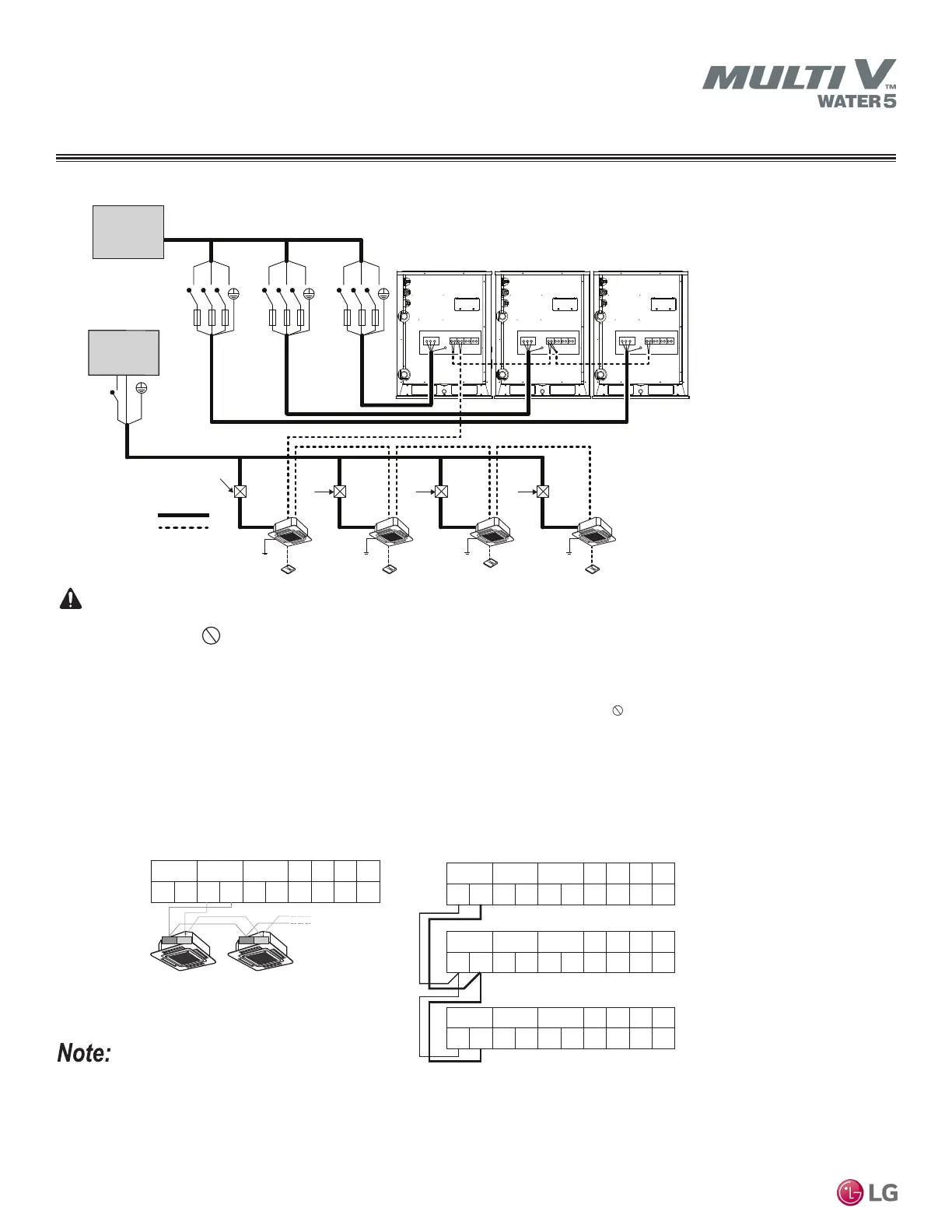

Figure 9: Close-up of Heat Pump Operation Communications Cable Schematic.

Heat Pump Operation

Communications Cable Between Main Outdoor Unit and Indoor Unit

B

ODU ID U CENTRAL DRY1 DRY2 GND 12 V

A B

A

B A

Main

Outdoor Unit Communication Terminal Block

B

ODU IDU CENTRAL DRY1 DRY2 GND 12 V

A B

A

B A

B

DRY1 DRY2 GND 12 V

A B

A

B A

B

DRY1 DRY2 GND 12 V

A B A

4(B)

3(A)

4(B)

3(A)

B

A

Communications Cable Between Main Outdoor Unit and Sub Outdoor Unit(s)

Main

Outdoor Unit Communication Terminal Block

Sub 1

Outdoor Unit Communication Terminal Block

Sub 2

Outdoor Unit Communication Terminal Block

Indoor Unit Indoor Unit

ODU IDU CENTRAL

ODU IDU CENTRAL

Loading...

Loading...