Do you have a question about the Lincoln Electric AC-225-S and is the answer not in the manual?

Keep your head out of the fumes and use adequate ventilation or exhaust to keep fumes and gases away from the breathing zone.

Protect your eyes, face, body, and skin with appropriate welding helmet, clothing, and gloves.

Do not weld or cut containers with hazardous substances or painted/plated parts without special precautions.

Includes California Proposition 65 warnings and general arc welding hazard awareness.

Follow specific safety guidelines for engine operation, refueling, and maintenance to prevent accidents.

EMF fields can interfere with pacemakers and may have unknown health effects. Minimize exposure.

The electrode and work circuits are electrically hot. Insulate yourself from work and ground using dry insulation.

Use proper filter shields for eyes and face, and flame-resistant clothing to protect skin from arc rays and spatter.

Avoid breathing welding fumes and gases. Ensure adequate ventilation or exhaust at the arc to keep breathing zones clear.

Remove fire hazards from the welding area. Cover openings to prevent sparks from starting fires.

Handle compressed gas cylinders with care to prevent damage. Secure cylinders upright and away from heat sources or arcs.

Ensure proper installation, grounding, and disconnect switch usage for electrically powered equipment.

Ensure the welder is off. Identify holder type and securely attach the electrode cable to the holder jaws.

Verify power supply adequacy. Connect the welder to a suitable receptacle and ensure proper grounding per electrical codes.

Securely fasten the work cable to the work clamp using the provided bolt and nut.

Use appropriate Lincoln parts for cable replacement. Substitution of larger sizes requires internal connections.

Select the correct output amperes using the current selector switch. Use proper polarity (AC, DC(+), DC(-)) for best results.

Understand duty cycle limitations to prevent overheating. Circuit breakers trip to protect the welder from overheating.

Refer to the 'Learning to Stick Weld' guide available on the Lincoln Electric website.

Consult the electrode guide for recommended electrode types, diameters, and current settings for various welding applications.

Learn and apply various stick welding motions (A through G) for different joint types and welding positions.

Use specific electrodes and maximum amperage for cutting steel and cast iron by melting and pushing metal away.

Hold a long arc perpendicular to the surface, push electrode through molten metal, and allow metal to drip through.

Routine preventative maintenance is not required. Contact an Authorized Field Service Shop for necessary repairs.

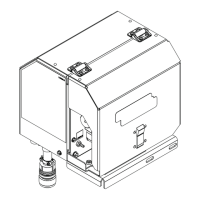

Visual representation of AC-225-S parts with numerical identification for reference.

Visual representation of AC/DC 225/125 parts with numerical identification for reference.

Details Lincoln Electric's policy on providing advice and information, including a disclaimer of liability and warranty.

| Brand | Lincoln Electric |

|---|---|

| Model | AC-225-S |

| Category | Welding System |

| Language | English |

Loading...

Loading...