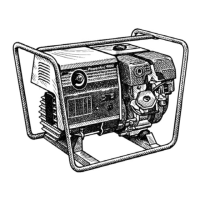

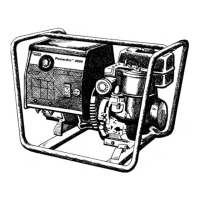

Do you have a question about the Lincoln Electric POWER-ARC 4000 and is the answer not in the manual?

| Brand | Lincoln Electric |

|---|---|

| Model | POWER-ARC 4000 |

| Category | Welding System |

| Language | English |

Covers electrical shock, fumes, arc rays, fire, cylinder, and EMF risks.

Provides key specs, engine details, output ratings, and pre-operation engine service.

Guides on placement, airflow, storage, and premises wiring.

Details output connections, cable setup, and machine grounding procedures.

Crucial safety, overview, controls, and engine start procedures.

Guides for using the unit as a generator and for welding tasks.

Techniques, settings, and practice for effective welding.

Safety rules and procedures for engine oil, filters, and spark plugs.

Covers cleaning, brushes, receptacles, and cable connections.

Guide to identifying and resolving common machine problems.

Includes wiring diagrams and dimensional drawings for reference.

Loading...

Loading...