Do you have a question about the Lincoln Electric IM536-D and is the answer not in the manual?

Specific warnings regarding cancer, birth defects, and reproductive harm.

Safety precautions for operating equipment with an engine.

Information on potential dangers of EMF fields and safety measures.

Guidelines to prevent fatal electric shock while operating the welder.

How to protect eyes and skin from arc rays and spatter.

Hazards associated with welding fumes and gases and how to mitigate them.

Precautions to prevent fires and explosions caused by welding sparks.

Safe handling and storage procedures for compressed gas cylinders.

Safety requirements for connecting and operating electrically powered equipment.

Safety measures specific to arc welding procedures.

Safety guidelines for transformer and rectifier welding machines.

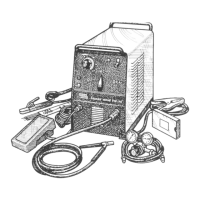

Detailed technical data, dimensions, and electrical requirements for the SP-125 Plus.

Critical safety warnings and guidelines to follow during installation.

Instructions for unpacking and identifying all parts included with the SP-125 Plus.

Guidelines for choosing a location and proper placement of the welder.

Connecting output cables, work clamp, and routing the work cable.

Procedures for installing the welding gun and connecting shielding gas.

Steps for connecting and safely preparing gas cylinders.

Electrical code requirements for input power supply and branch circuits.

Critical safety warnings for operating the welding machine.

Overview of the welder's capabilities, design, and features.

Detailed explanation of the welder's controls and how to adjust them.

Step-by-step guide for loading welding wire onto the spool.

Instructions for threading wire and adjusting the friction brake.

Proper use and setup of shielding gas for welding processes.

Core techniques and steps for performing a weld.

Guidance on choosing between GMAW and FCAW processes.

How to adjust the machine for different wire sizes and types.

Specific instructions and considerations for using the FCAW process.

Explanation of output, thermal, and wire feed overload protection features.

Explanation of the electrical circuit involved in arc welding.

Detailed explanation of the Gas Metal Arc Welding process.

Factors to consider when selecting the appropriate welding process.

Information on common metals and different welding joint types.

Overview of different welding joints and their execution.

Methods for performing vertical-up and vertical-down welds.

Techniques and considerations for welding in overhead positions.

Steps to configure the welder for the Innershield FCAW process.

Key manipulations and positions for effective FCAW welding.

Proper methods for initiating the arc and maintaining optimal electrical stickout.

Techniques for controlling welding speed based on puddle appearance.

Practical tips for improving general welding performance.

Exercises and advice for mastering core welding skills.

Configuration steps for the Gas Metal Arc Welding process.

Key manipulations and positions for effective GMAW welding.

Practical tips for improving MIG welding performance.

Exercises to develop proficiency in MIG welding techniques.

Solutions for common weld defects like porosity, spatter, and poor penetration.

Best practices for handling the welding gun to prevent feeding issues.

Recommended settings for various welding processes and materials.

How to set polarity and orient the drive roll for different welding wires.

Descriptions and part numbers for optional accessories.

Steps to convert the welder for the Innershield FCAW process.

List of available replacement parts and their part numbers.

Critical safety warnings before performing any maintenance.

Scheduled maintenance activities for optimal welder performance.

Steps for cleaning the gun cable liner and configuring wire feeder components.

Instructions for replacing contact tips and adjusting the drive roll.

Steps to configure for Innershield wire, including contact tip and nozzle.

Step-by-step instructions for replacing the gun liner.

Procedures for disassembling and working on the gun handle.

Instructions on how to effectively use the troubleshooting section.

Common output issues and their potential causes and solutions.

Troubleshooting steps for wire feeding issues.

Solutions for problems related to shielding gas flow.

Troubleshooting steps for unstable arcs and poor starting.

Schematic diagram illustrating the electrical connections of the SP-125 Plus.

| Brand | Lincoln Electric |

|---|---|

| Model | IM536-D |

| Category | Welding System |

| Language | English |

Loading...

Loading...