TECHNICAL SPECIFICATIONS

Wire Feed Wire Size Dimensions Net

Product Product Input Output Capacity Speed Range Range H x W x D Weight

Name

(1)

Number Power Current / Duty Cycle ipm (m/min) in (mm) in (mm) lbs (kg)

LF-72 Base Model K2327-1 24-42 VAC 500 Amps @ 60% 50-800 Solid Cored 11.1 x 10.2 x 12.9 44

(with gun) 50/60 Hz 400 Amps@ 100% (1.3-20.3) .023-1/16 .030-5/64 (282 x 259 x 328) (20)

9 Amps (0.6-1.6) (0.8-2.0)

LF-72 Base Model, K2327-4 27

(no gun, no cable) (12)

LF-72 Bench Model, K2327-2 12.6 x 10.9 x 22.5 53

Standard Duty (320 x 277x 572) (24)

LF-72 Bench Model, K2327-3 15.3 x 13.0 x 27.7 68

Heavy Duty (389 x 330 x 704) (31)

LF-74 Base Model K2426-1 600 Amps @ 60% 100-800 .030-5/64 11.1 x 10.2 x 12.9 46

500 Amps@ 100% (2.5-20.3) (0.8-2.0) (282 x 259 x 328) (21)

LF-74 Bench Model, K2426-2 15.3 x 13.0 x 27.7 71

Heavy Duty (389 x 330 x 704) (32)

LF-74 Bench Model, K2426-3 50-400 .030-3/32 71

Heavy Duty, Extra Torque (1.3-10.1) (0.8-2.4) (32)

Output

or

Input

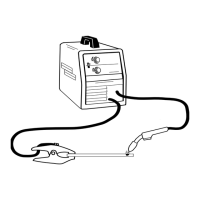

Designed for MIG and cored wire welding in job shop and manufacturing

environments, the rugged LF-72 and LF-74 wire feeders are built to

deliver reliable performance day after day. The heart of these feeders

is the highly engineered 2-roll or 4-roll MAXTRAC™ wire drive

system, delivering strong and consistent feeding force for tough

applications.

Select the 2-roll LF-72 for most .035-.045 wire applications.

Select the 4-roll LF-74 for large diameter wires, longer

gun cables or long boom conduit or hard automation

applications.

Processes

MIG, Pulsed, Flux-Cored

LF-72 and LF-74 Wire Feeders

2-Roll or 4-Roll Heavy Duty Industrial Feeders

Publication E8.11 8/06

LF-74 Bench Model, Heavy Duty, Extra Torque, K2426-3

LF-72 Bench Model, Standard Duty, K2327-2

(Shown with optional wire.)

SEMIAUTOMATIC WIRE FEEDERS

• Patented MAXTRAC™ heavy-duty cast aluminum wire drive system

provides reliable feeding and durability.

• Brass-to-brass gun connections for better electrical conductivity that

results in better arc performance.

• Totally tool-less drive rolls and wire guide installation. Two or four

gear-driven wire drive rolls slide on and off easily!

• Calibrated wire feed speed dial for precise and accurate settings.

• Rugged, industrial-grade wire feeder motor.

• In addition to great mild steel performance, these feeders deliver

positive arc starting and feeding with stainless steel, aluminum and

flux-cored wires!

• Control cable connector with a Spin-Nut™ makes connecting the

control cable a simple twist-of-the-wrist.

• Totally enclosed wire drive.

• Manufactured under a quality system certified ISO 9001

requirements and ISO 14001 environmental standards.

• Three-year warranty on parts and labor.

Advantage Lincoln

•

See selection guide on page 4.

(1)

www.lincolnelectric.com

Loading...

Loading...