Do you have a question about the Lincoln Electric LN-9 SVM127-A and is the answer not in the manual?

| Brand | Lincoln Electric |

|---|---|

| Model | LN-9 SVM127-A |

| Category | Welding System |

| Language | English |

Covers engine safety, EMF, and general precautions.

Covers electric shock, arc rays, fumes, and gases risks.

Covers fire, sparks, gas cylinders, and related safety.

Details model specs, wire diameters, dimensions, and temperature ranges.

Covers power input assembly, various source connections, and wiring.

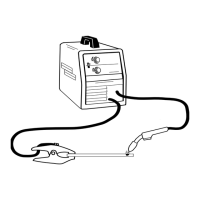

Details work cable, direct work lead, and machine grounding.

Overview of the wire feeder and compatible power sources.

Covers loading Readi-Reels, spools, and coils.

Details test welds, response settings, and control adjustments.

Describes various stands, adapters, and mounting hardware.

Details available gun and cable options for different processes.

Lists optional kits for enhanced functionality.

Covers drive rolls, guide tubes, and reel mounting upkeep.

Details control box and motor/gearbox inspection procedures.

Specifies connection standards for gun cables.

Explains overall function and power input circuits.

Details trigger, shutdown, and arc voltage control logic.

Describes the role of individual PCBs within the system.

Instructions on how to diagnose and locate issues.

Lists and addresses issues with wire feed and meter readings.

Details procedures for testing transformers, motors, and PC boards.

Comprehensive schematic of system wiring.

Functional block diagram of system circuits.

Detailed schematics for meter, trigger, and tach boards.

Loading...

Loading...