Do you have a question about the Lincoln Electric Vantage LE500X and is the answer not in the manual?

Essential personal protective equipment for welding safety.

Safety considerations for specific scenarios and additional precautionary measures.

Warnings regarding diesel exhaust and product chemicals.

Safety precautions for engine-powered equipment operation.

Risks of EMF, effects on pacemakers, and minimization procedures.

Dangers of electric shock, arc rays, and welding fumes, with necessary precautions.

Precautions against fire and explosion from welding sparks and hot materials.

Safety measures for handling compressed gas cylinders to prevent explosion.

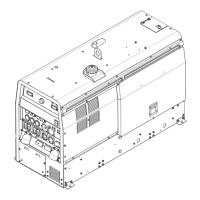

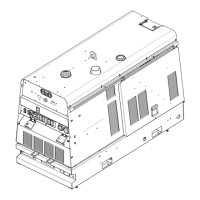

Overview of the diesel engine driven welding power source and its technology.

Details on engine, dimensions, capacities, and electrical ratings.

Explanation of VRD function, connections, and switch operation.

Guidelines for placing the welder for optimal airflow and exhaust venting.

Instructions for storing the machine properly when not in use.

Information stating that machines cannot be stacked.

Recommendations for operating the machine at an angle for optimal engine performance.

Proper methods and precautions for lifting the machine using the lift bale.

Warnings and precautions to prevent injury from falling equipment during lifting.

Guidelines for safely towing the equipment with a trailer.

Considerations for installing the welder on a service truck or trailer.

Engine oil type, checking the level, and break-in period oil checks.

Instructions for using ultra-low sulfur diesel fuel and safe fueling practices.

Information on the coolant mixture and system, warning about hot coolant.

Procedures for connecting the battery, including safety warnings about gases and acid.

Information on the need for spark arrestors and potential engine impact.

Explanation of the air cleaner service indicator for filter life.

Instructions for attaching and positioning the exhaust outlet pipe.

Guidelines for grounding the machine frame for electrical safety.

Description of available auxiliary power receptacles and voltage settings.

Details on GFCI protection for 120V receptacles and testing.

Routing and connecting electrode and work cables, and cable size recommendations.

Specific cable requirements and limitations for pulse welding applications.

How cable inductance affects welding performance and how to minimize it.

How voltage sensing works with ArcLink feeders and process requirements.

Connecting the machine to ArcLink compatible wire feeders for communication.

How CrossLinc enables remote control without cables and its compatibility.

How to connect remote controls for various welding modes.

Explanation of terminal settings for hot/cold welding and ArcLink modes.

High frequency module for superior starting and control in TIG welding.

Details on installing and using the spool gun module for welding.

Essential safety guidelines to read before operating the machine.

Suitable welding processes and applications for the machine.

Extra safety measures for operating the welder, including door and panel usage.

Procedures and safety warnings for adding diesel fuel to the machine.

Guidance on operating the engine during its initial break-in period.

Pre-start checks for the engine, including oil and coolant levels.

Step-by-step instructions for starting the engine, including auto idle.

How to properly stop the engine after operation.

Description of dashboard gauges for fuel, oil, temperature, and battery.

How digital meters display preset and actual output values.

Indicates active CrossLinc communication between the machine and device.

How to use the output control knob to set welding parameters.

Controls output enabling and remote versus local operation.

How the arc control knob adjusts arc force or inductance based on mode.

Description of the six selectable welding modes available.

Toggles output for wire feeder voltage requirements.

Connector for attaching an ArcLink wire feeder control cable.

Controls engine start, stop, and idle speed settings.

Description of circuit breakers protecting power circuits and receptacle types.

Details on 3-phase receptacle, 120V receptacles, GFCI modules, ground stud, status lights, thermal light, and diagnostic plug.

How to adjust hot start settings for different weld modes.

How to select synergic or non-synergic CV modes for welding.

How to enable or disable CrossLinc for CV welding modes.

Procedure to reset stored values to factory defaults.

How to access test modes for grid load testing.

Essential safety guidelines to read before performing a weld.

Definition of duty cycle and its importance for machine operation.

Explanation of Non-Synergic and Synergic welding modes.

How to use Weld Mode, Wire Feed Speed, Amps, and Volts controls.

How to use CC-STICK mode for various welding positions and arc control.

Using downhill pipe mode for controlled current and arc length.

How to perform DC TIG welding using touch start and cable size importance.

Using TIG module for high frequency, grounding, and output control.

How to set up and use CV-WIRE mode with wire feeders, including synergic and non-synergic options.

How ArcLink mode disables machine controls and uses feeder interface for operation.

How to set output control for arc gouging electrodes and high idle recommendation.

How CrossLinc provides remote control via electrode cable and its benefits.

Guidelines for paralleling machines for combined output, requiring CC-STICK mode.

How to operate the auxiliary power outlets for single and three phase power.

How welding loads affect available auxiliary power output.

Wire feeders and remotes that utilize CrossLinc technology.

Trailers, power plugs, and polarity switches for enhanced functionality.

High frequency module for superior starting and control in TIG welding.

Various wire feeders and guns for different welding applications.

Adapters for quick cable changeovers.

Other Lincoln Electric welders and plasma cutters that can be powered.

Essential safety rules before performing maintenance tasks.

Daily and periodic checks and cleaning procedures for the machine.

Reference to the engine operator's manual for maintenance items like oil, filters, and belts.

Instructions and warnings for servicing the air filter element.

Procedures and warnings for changing the fuel filter and water separator.

Information on checking coolant levels and system components.

Detailed steps for checking coolant levels and refilling the system.

Procedures and safety warnings for handling, charging, and connecting the battery.

Steps for draining engine oil, changing the oil filter, and refilling.

How to check fan belt tightness and its importance.

Inspecting and replacing nameplates and warning decals for legibility.

Guidelines for storing the machine in protected areas.

Explanation of the three-step procedure for diagnosing and resolving problems.

Common engine problems, their possible causes, and recommended actions.

Common machine function issues, possible causes, and recommended actions.

| Max Output | 500A |

|---|---|

| Processes | Stick, TIG, MIG, Flux-Cored, Gouging |

| Generator Type | Brushless |

| Output Range | 5-500 amps AC/DC |

| Engine | Diesel |

| Output Voltage Range | 20-250V |

| Duty Cycle | 100% at 400A/36V |

| Input Power | Diesel |

Loading...

Loading...