Do you have a question about the Lincoln Electric Vantage 441X/LE500X and is the answer not in the manual?

| Model | Vantage 441X/LE500X |

|---|---|

| Type | Engine-driven Welding Generator |

| Processes | Stick, TIG, MIG, Flux-Cored, Gouging |

| Input Power | Not Applicable (Engine-Driven) |

| Input Voltage | Not Applicable (Engine-Driven) |

| Input Current | Not Applicable (Engine-Driven) |

| Auxiliary Power | 120/240 Volts |

| Engine | Kubota |

Emphasizes reading the manual, thinking before acting, and overall safe operation.

Details necessary personal protective equipment for welding safety.

Hazards associated with diesel exhaust and welding fumes/gases.

Specific safety precautions for operating engine-driven equipment.

Precautions and procedures to minimize exposure to EMF fields.

Dangers of electric shock and methods to prevent it during welding.

Protection against harmful arc rays and burns.

Dangers of welding fumes and gases and ventilation requirements.

Safety measures to prevent fires and explosions caused by sparks or hot materials.

Precautions for handling compressed gas cylinders to prevent explosions.

Safety requirements for electrically powered welding equipment.

Details about the Perkins diesel engine, including power, displacement, and battery.

Output ranges for various welding modes and auxiliary power capacities.

Dimensions and weight of the welding machine.

Critical safety warnings and advice before installing the equipment.

Explanation of the VRD function and its switch operation.

Guidelines for proper placement and airflow for optimal performance.

Instructions for storing, stacking, and operating the machine at angles.

Derating guidelines for operation at high altitudes and temperatures.

Advice and warnings for starting the engine in cold weather conditions.

Recommendations for safely towing the welding equipment.

Mounting and installation considerations for service vehicles.

Information on engine oil, fuel, and the cooling system.

Procedures and warnings for connecting and handling the battery.

Information on spark arrestor requirements and potential issues.

Explanation of the air cleaner service indicator.

Guidelines for properly grounding the machine frame for safety.

Details on available auxiliary power outlets and their ratings.

Information on circuit breakers protecting auxiliary power circuits.

Steps for connecting the welder for standby or emergency power.

Recommendations for selecting appropriate cable sizes based on current and duty cycle.

Specific cable requirements for pulse welding performance.

Step-by-step instructions for installing welding cables.

How cable inductance affects welding performance and how to minimize it.

Guidelines for connecting control cables to the welder.

How CrossLinc technology enables remote control without cables.

How to connect and use remote controls for different welding modes.

How to select between hot/cold welding terminals based on mode.

General steps and safety for connecting accessories to the welder.

Diagram and parts list for setting up CrossLinc in CV mode.

Diagram and parts list for a dual arc setup.

Diagram and parts list for installing the TIG module.

Diagram and parts list for installing the spool gun module.

Essential safety warnings and precautions before operating the machine.

Lists applications for which the welder is suitable and not recommended.

Specific safety measures for operating the welder, like keeping doors closed.

Safe procedures for fueling the diesel engine, including warnings.

Guidelines for the initial break-in period for the engine.

Step-by-step instructions for starting and stopping the engine.

Displays engine status, oil pressure, coolant temp, fuel level, and battery voltage.

Displays preset/actual welding voltage and current with a memory feature.

Explains the CrossLinc light and the output control knob functions.

Details the weld terminals switch and arc control knob functions.

Describes selecting weld modes and controlling engine idle/run states.

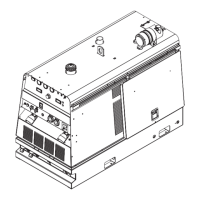

Describes start switch, connectors, VRD indicators, and hidden menu access.

Details the local/remote switch and wire feeder voltmeter polarity switch.

Information on receptacles, GFCI, ground stud, status lights, diagnostic plug, and breakers.

How to adjust hot start settings for different weld modes.

Options for selecting synergic or non-synergic CV modes.

How to enable or disable CrossLinc for CV welding modes.

Procedure to reset stored values to factory defaults.

How to access test modes for grid load testing.

Critical safety warnings and procedures for making a weld.

Definition and importance of duty cycle for welding equipment.

Explains welding modes, wire feed speed, amps, and volts controls.

Operation details for CC-Stick and Downhill Pipe welding modes.

How to perform DC TIG welding using the touch start method.

Using TIG modules and requirements for high frequency equipment.

Specific settings and procedures when using the K930-2 TIG module.

How to operate in CV-Wire mode with synergic and non-synergic settings.

How to set up and operate the arc gouging mode.

How to use the ArcLink mode for wire feeder control.

How pulse welding parameters like Trim and UltimArc™ affect the weld.

How CrossLinc enables remote control via electrode cable.

Procedures for paralleling machines for combined output.

How to operate the generator for auxiliary power supply.

How auxiliary power capacity is affected by welding loads.

Procedures for testing GFCI modules and identifying failures.

Table showing fuel consumption rates for various operating scenarios.

Details on CrossLinc feeders, spark arrestors, and engine service kits.

Various accessories including trailers, plugs, and polarity switches.

Information on TIG modules, wire feeders, guns, and power sources.

Details on cable adaptors and additional welding power sources.

Critical safety warnings before performing maintenance.

Daily and periodic checks and cleaning for the machine.

Instructions for inspecting and maintaining brushes and slip rings.

References the service plan for oil, air filter, fuel filter, and cooling system maintenance.

Instructions and warnings for servicing the air filter element.

Procedures and warnings for changing fuel filters.

How to check coolant levels and drain/refill the cooling system.

Procedures and warnings for handling, charging, and connecting batteries.

Steps for changing engine oil and the oil filter.

How to check fan belt tightness and maintain nameplates/decals.

Instructions for storing the machine in protected areas.

Procedures for testing GFCI modules and identifying failures.

Explanation of the three-step procedure for diagnosing problems.

Possible causes and actions for engine crank/start issues.

Troubleshooting engine shutdown and rough running issues.

Diagnosing battery charging problems and idle speed issues.

Troubleshooting issues with welding output and remote control.

Diagnosing problems with auxiliary power and GFCI tripping.

Essential safety warnings in multiple languages for operator protection.

Policy on Lincoln Electric's advice, liability, and product selection responsibility.

Loading...

Loading...