Do you have a question about the Lincoln Electric Maverick 325X and is the answer not in the manual?

Guidance on wearing appropriate safety gear for welding operations.

Precautions regarding fire hazards and the safe handling of welding fumes.

Legal warnings regarding diesel exhaust and welding fumes.

Safety advice and precautions for performing arc welding.

Specific safety measures for operating and maintaining engine-powered equipment.

Information on potential EMF hazards and recommended safety practices.

Details on the dangers of electric shock and necessary protective measures.

Risks associated with arc rays and hazardous fumes during welding.

Safety guidelines to prevent fires and explosions from welding sparks.

Precautions for handling compressed gas cylinders and electrical equipment.

Overview of EMC standards and compatibility requirements.

Guidance on installing equipment and assessing the EMC environment.

Techniques and methods to minimize electromagnetic interference.

Explanation of common graphic symbols used in the manual.

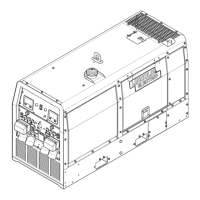

Details on engine, welding, and auxiliary power ratings.

Machine size, weight, and fluid capacities.

Key safety precautions for qualified personnel during installation.

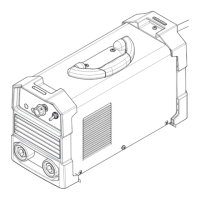

Functionality and safety benefits of the Voltage Reduction Device.

Proper placement and airflow guidelines for the welder.

Guidelines for safely storing and lifting the welding machine.

How altitude and temperature affect machine performance.

Considerations for towing the unit and initial engine checks.

Procedures for managing fuel, coolant, and battery systems.

Installation details for the muffler outlet and spark arrestor.

Description of the LCD display and main operational controls.

Details on ports and the main output adjustment knob.

Information on circuit breakers and power receptacles.

Connection points for welding and engine idle control.

Proper methods for connecting electrode and work cables.

Guidelines for ensuring proper machine grounding for safety.

Instructions for connecting and utilizing remote controls.

Effects of cable inductance and setup for standby power.

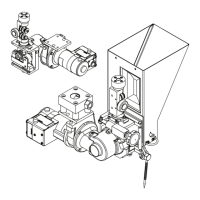

Procedures for setting up wire feeders and spool guns.

Information on using the machine for auxiliary power generation.

Important safety notes and precautions for auxiliary power usage.

Instructions for connecting external wire feeders to the welder.

Explanation of CrossLinc for wireless remote control capabilities.

Guidance on using various electrical devices with the welder.

Essential safety rules to follow before operating the machine.

Procedures for starting the engine and safely adding fuel.

Typical welding and generator applications for the Maverick 325X.

How to use the generator and configure the auto-start feature.

Proper procedure for breaking in the engine during initial use.

Procedures for starting the engine, including cold weather considerations.

Data on fuel usage based on different operating loads and settings.

Understanding duty cycle and selecting appropriate electrodes.

Operating procedures for Constant Current Stick and Downhill Pipe welding.

How to initiate and perform TIG welds using touch start.

Using TIG modules and setting up remote controls for TIG welding.

Operating the machine in Constant Voltage wire welding mode.

Procedures for arc gouging and connecting machines in parallel.

Using the machine's generator for auxiliary power.

Managing combined welding and auxiliary power demands.

How to navigate and use the machine's display interface.

Accessing weld modes and settings from the main home screen.

Setting up and performing basic stick welding.

Understanding the display readings during stick welding.

Adjusting remote control settings and arc force for stick welding.

Utilizing the hot start feature for improved arc ignition.

Setting up and performing MIG/FCAW welding.

Understanding MIG-specific options like Pinch Mode.

Explanation of CrossLinc for wireless remote control.

Setting up and performing welds with a spool gun.

Using synergic and normal control modes for spool guns.

How synergic mode adjusts voltage with wire speed.

Using pulse mode for lower heat input welding.

Utilizing spot time for consistent tack welds.

Checking engine service indicators like oil, filters, and belt life.

Viewing engine hours, temperature, voltage, and RPM.

Configuring auto-start features and security PINs.

Adjusting screen brightness and performing machine calibration.

Controlling variable speed and restoring default settings.

Enabling and managing operator security PINs.

Procedure for machine selection after replacing a PC board.

Step-by-step instructions for calibrating the spool gun.

List of recommended parts for engine maintenance.

Tracking arc hours, utilization, and fuel savings.

List of available accessories that can be installed in the field.

Essential safety precautions for performing maintenance.

Regular inspection and fluid level checks for daily/weekly maintenance.

Guide to engine-specific maintenance tasks and references.

Detailed steps for cleaning and replacing the air filter.

Procedures for servicing fuel filters and the cooling system.

Maintenance for labels, fan belts, and engine oil changes.

Precautions for battery installation, charging, and handling.

Preventing electrical damage and procedures for brush maintenance.

Instructions on how to effectively use the troubleshooting section.

Common issues and solutions for auxiliary power output problems.

Troubleshooting common engine starting and running issues.

Resolving problems with welding output and arc stability.

Troubleshooting VRD display errors and communication failures.

Diagnostic codes for engine malfunctions and their corrective actions.

Schematic of the machine's electrical connections and components.

Physical size, weight, and hole locations for mounting.

Information regarding customer service and technical assistance.

| Brand | Lincoln Electric |

|---|---|

| Model | Maverick 325X |

| Category | Welding System |

| Language | English |

Loading...

Loading...