Do you have a question about the Lincoln Electric SVM189-B and is the answer not in the manual?

Safety guidelines specific to engine-powered welding equipment.

Precautions regarding electric and magnetic fields during welding.

State of California warnings regarding engine exhaust emissions.

Critical safety advice on preventing electric shock during welding.

Safety measures to protect against arc rays and their effects.

Guidelines for safe handling of welding fumes and gases.

Precautions to prevent fires and explosions from welding sparks.

Safety warnings related to compressed gas cylinders.

Safety instructions for operating electrically powered equipment.

Key technical details and ratings for welding machines.

Guidance on choosing an appropriate and safe location for the welder.

Essential safety measures during the installation process.

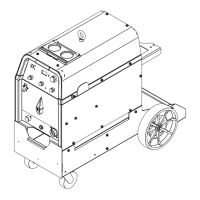

Visual guide to identify and locate machine components.

Overview of the machine's capabilities and welding processes.

Explanation of machine controls and adjustment procedures.

Steps and items required for setting up flux-cored welding.

Steps and items required for setting up MIG welding.

Procedure for connecting and installing shielding gas for MIG welding.

Instructions for setting up aluminum welding using an optional spool gun.

Details on various spool gun kits and related accessories.

Information on utility and welding carts for transporting equipment.

Specs, unpacking, safety, and component ID for spool gun.

Procedures for installing, connecting, and loading wire for spool gun.

Critical safety guidelines before performing maintenance.

Recommended regular maintenance procedures for the welder.

Procedures for cleaning and maintaining the welding gun and cable.

Guide to locating and identifying major internal machine components.

An overview of the welding machine's capabilities and types.

Explanation of input voltage, fan motor, and main transformer function.

Description of how output voltage is controlled and rectified.

Explanation of thermal, overload, and motor protection systems.

Instructions on how to effectively use the troubleshooting guide.

Procedures for diagnosing and troubleshooting PC board issues.

Categorized list of common machine problems and symptoms.

Step-by-step guides for replacing key machine components.

Reference values for retesting machine after repair.

Schematics showing electrical connections for various machine configurations.

Detailed schematics illustrating internal circuit functions and layouts.

| Model | SVM189-B |

|---|---|

| Welding Processes | MIG |

| Input Phase | 1-Phase |

| Input Current | 20A |

| Duty Cycle | 20% |

| Wire Size Range | 0.030-0.045 in |

Loading...

Loading...