Do you have a question about the Lincoln LN-25 IRONWORKER and is the answer not in the manual?

Covers general warnings, engine operation safety, and electromagnetic field hazards.

Details risks from electric shock, arc rays, fumes, gases, fire, and explosions.

Addresses cylinder handling safety and electrical precautions for powered equipment.

Details conformity with European Community Council Directive and harmonized standards for EMC.

Explains electromagnetic emission and potential interference from electrical equipment.

Outlines user responsibility for installation, use, and resolving detected electromagnetic disturbances.

Guides users in assessing potential electromagnetic problems in the surrounding area before installation.

Instructs users to examine cartons and equipment for damage immediately upon receipt.

Prompts users to record equipment identification details for future reference.

Provides instructions for registering the machine online or via fax.

Lists detailed technical specifications including voltage, current, gearing, dimensions, and temperature range.

Highlights critical safety warnings and precautions specific to the installation process.

Explains how to configure the wire drive, including changing the gun receiver bushing.

Provides diagrams for connecting power sources to the LN-25 Ironworker using various connectors.

Covers essential safety precautions and explains graphic symbols used in the manual and on the machine.

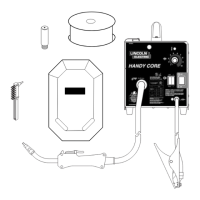

Describes the physical and functional aspects of the LN-25 Ironworker and its limitations.

Details the front panel controls, wire feed speed adjustments, and calibration procedures.

Lists equipment that comes pre-installed with the wire feeder.

Describes various drive roll kits available for different wire types and sizes.

Lists different gun receiver bushings for compatibility with various welding guns.

Details spindle adapters for different spool sizes and wire feed speed meters.

Emphasizes safety measures to be taken before performing any maintenance tasks.

Outlines regular checks and cleaning tasks for cables, hoses, and terminals.

Describes periodic cleaning of drive rolls, guides, and internal components.

Explains the three-step process for identifying and resolving machine malfunctions.

Lists common issues, their possible causes, and recommended courses of action.

Presents the electrical wiring diagram for the LN-25™ Pro Ironworker.

Shows the physical dimensions and outline of the LN-25™ Ironworker.

| Duty Cycle | 60% at 250A |

|---|---|

| Wire Feed Speed Range | 50-700 IPM |

| Wire Diameter Range | 0.045 inches |

| Input Power | 230V, 460V, 575V |

| Dimensions | 17.5 x 12.5 x 13.5 inches |

Loading...

Loading...