13

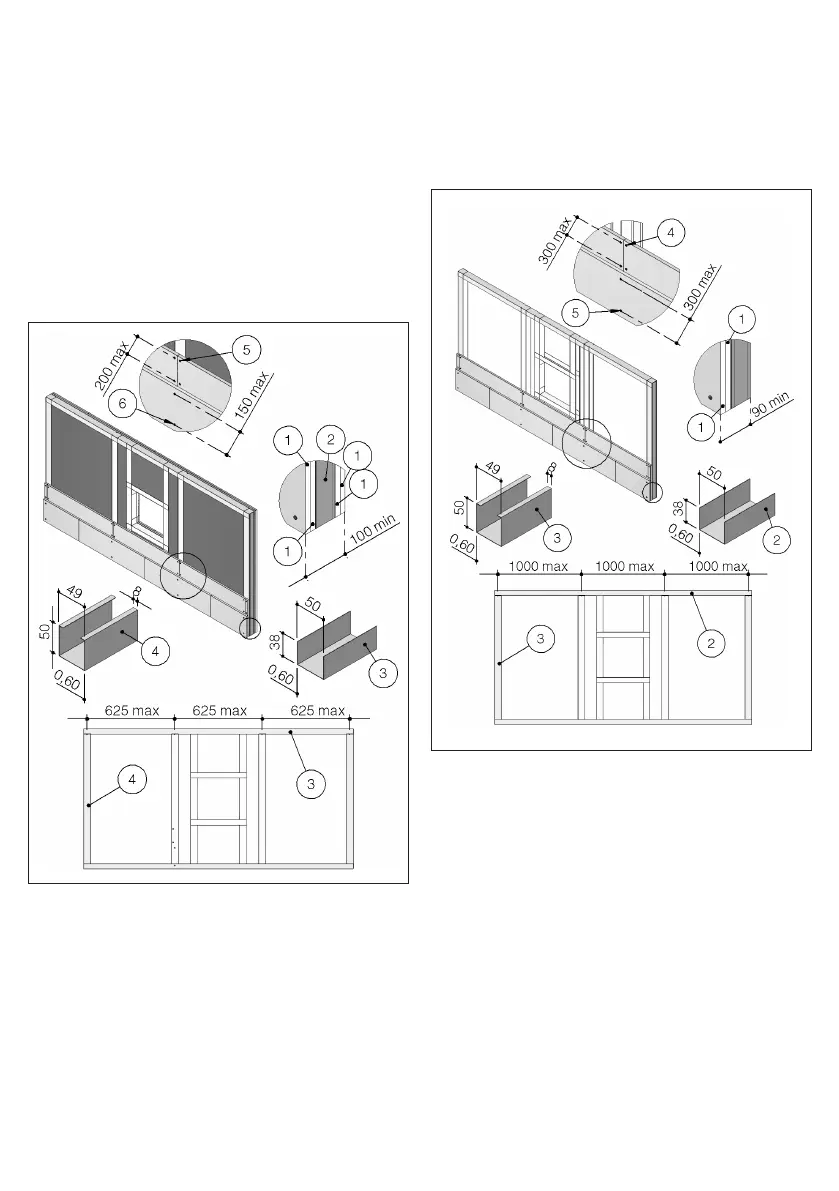

• vertical prole xing with selfthreading screws or by clinching to

the bottom horizontal prole and insertion in the top horizontal

prole;

• proles xed using self-threading screws or by clinching on every

intersection.

• installation of a frame around the damper with base and height as

shown in the installation instructions;

• rock wool lling which has minimum density 100 kg/m³:

• each side is made from two plasterboard layers 12,5 mm minu-

mum thick, unalinged to avoid alignment between the joints of

the layer above and below.

• the front plasterboards layers are xed using long enough screws

to pass through the lower plasterboard and attach to the steel pro-

le underneath.

1. Plasterboard thickness 12,5 mm

2. Rock wool, 100 kg/m³

3. Horizontal U-shaped prole

4. Vertical C-shaped prole

5. Self-drilling screw Ø 3,5 X 25 mm

6. Self-drilling screw Ø 3,5 X 35 mm

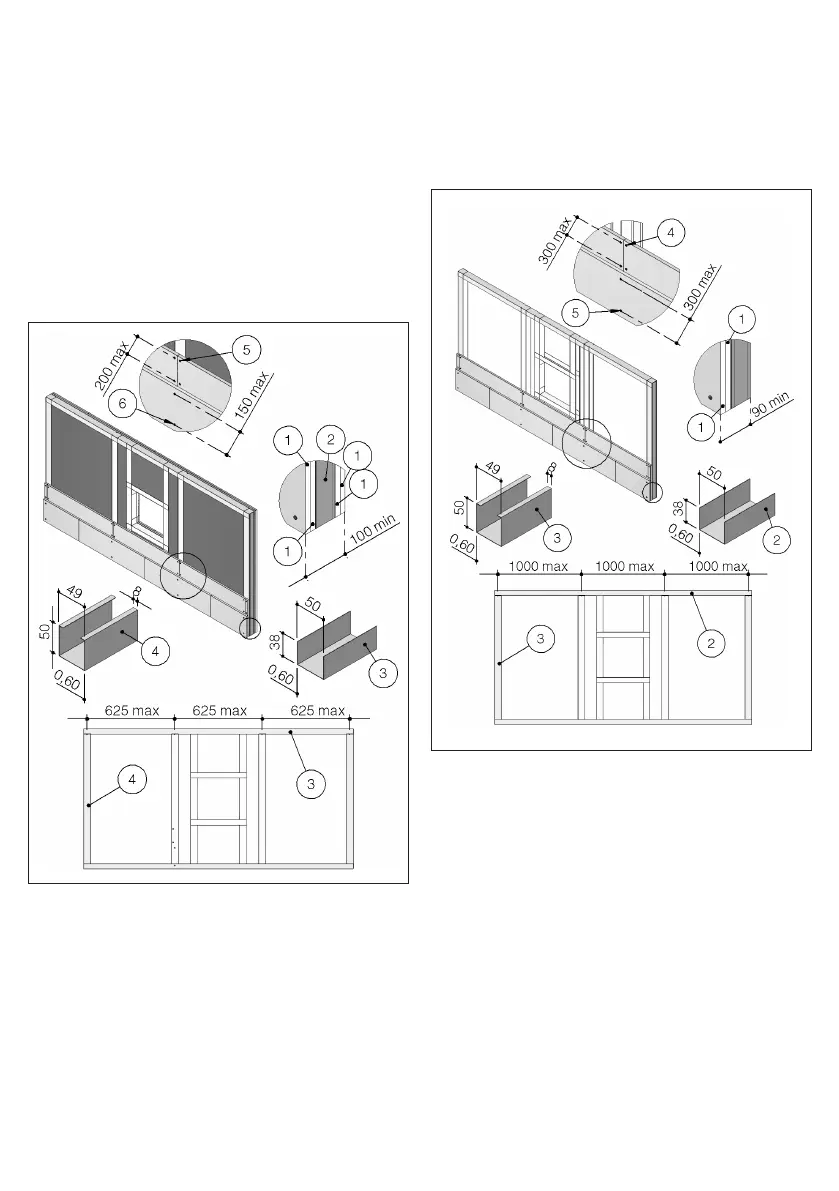

Light plasterboard vertical walls (Shaft wall)

The following indications are given for the installation walls:

• U-shaped horizontal metal frame (minimum width 50 mm) and

C-shaped vertical frame (minimum width 49 mm) made from

sheet metal (minimum thickness 0,6 mm);

• vertical proles placed with a maximum spacing of 1000 mm be-

tween each other;

• vertical prole xing with selfthreading screws or by clinching to

the bottom horizontal prole and insertion in the top horizontal

prole;

• proles xed using self-threading screws or by clinching on every

intersection.

• installation of a frame around the damper with base and height as

shown in the installation instructions;

• one side is made from two plasterboard layers 20 mm minumum

thick, unalinged to avoid alignment between the joints of the layer

above and below;

• the front plasterboards layers are xed using long enough screws

to pass through the lower plasterboard and attach to the steel pro-

le underneath.

1. Plasterboard thickness 20 mm

2. Horizontal U-shaped prole

3. Vertical C-shaped prole

4. Self-drilling screw Ø 3,5 X 35 mm

5. Self-drilling screw Ø 3,5 X 55 mm

Loading...

Loading...