17

Filling

Fill the space between the damper and the wall using Fire Batt

(Weichschott) sealing made from two rock wool panels with mini-

mum thickness of 50 mm and minimum density of 140 kg/m³.

The panels must be covered on both faces of the wall with endo-

thermic varnish type PROMASTOP E PASTE or HILTI CFS-CT (mini-

mum thickness of 1 mm) and with an internal perimeter sealant type

PROMASTOP E PASTE or HILTI CFS-S ACR (minimum thickness of 1

mm).

Fire resistance classication

Hole size “D1 x D2”

[mm]

Damper protrusion from

the wall “E”

[mm]

Wall minimum thickness “S”

[mm]

Sealing

Rigid wall

EI 120 S Installation within rigid vertical wall with Fire Batt (Weichschott) sealing

Wall minimum density 550

kg/m³

EI 120 S

(300 Pa)

(B+800 max) x (H+800

max)

185 100

Rock wool 140 kg/

m³ and endothermic

varnish sealing

Flexible wall

EI 120 S Installation within vertical light wall (plasterboard) with Fire Batt (Weichschott) sealing

Wall rock wool minimum

density 100 kg/m³

EI 120 S

(300 Pa)

(B+800 max) x (H+800

max)

185 100

Rock wool 140 kg/

m³ and endothermic

varnish sealing

EI 120 S Installation within vertical light wall (plasterboard) with Fire Batt (Weichschott) sealing

Wall minimum density 995

kg/m³

EI 120 S

(300 Pa)

(B+800 max) x (H+800

max)

185 100

Rock wool 140 kg/

m³ and endothermic

varnish sealing

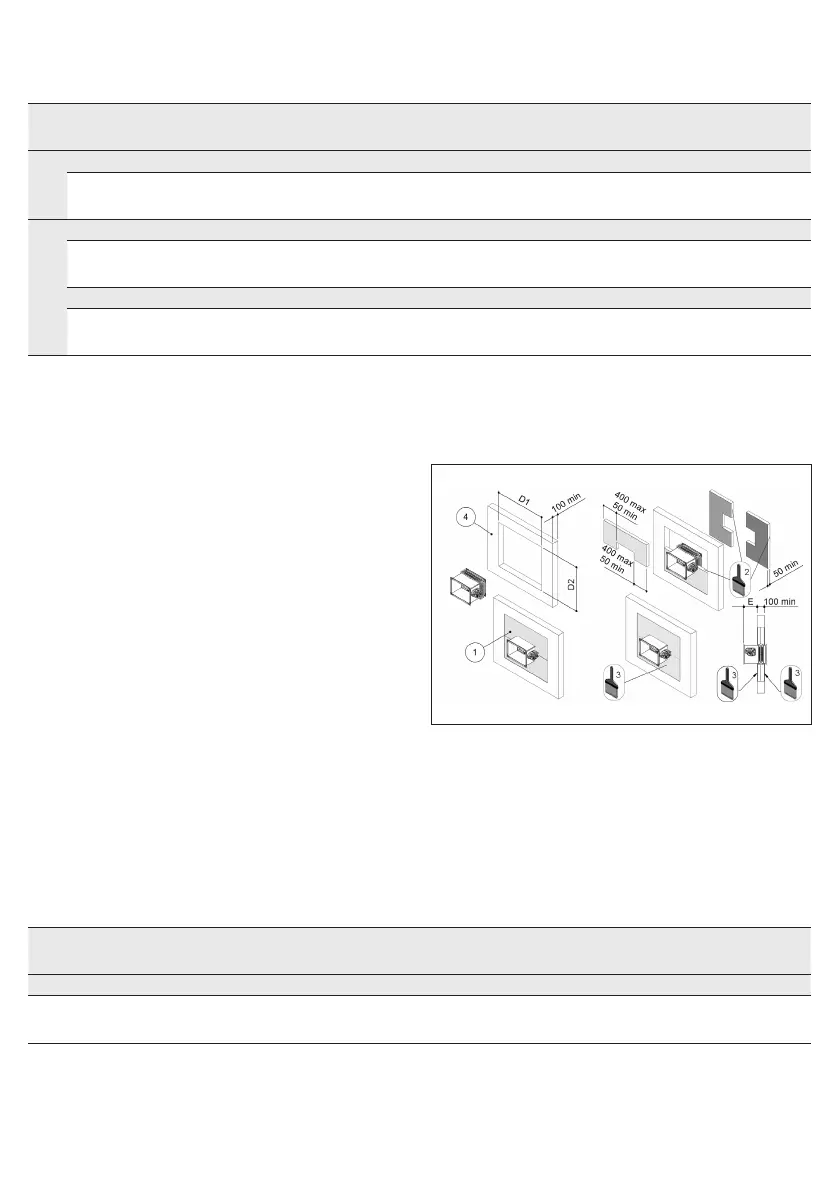

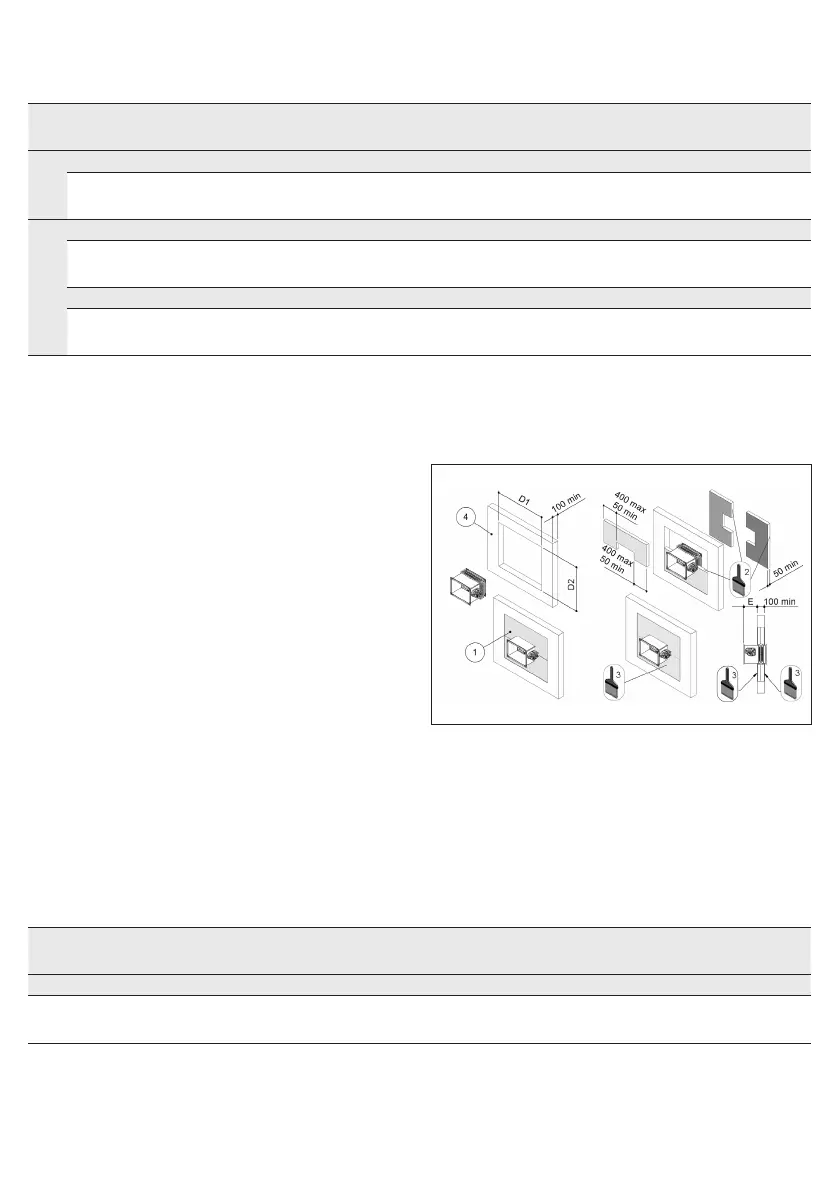

B Nominal base of the damper

H Nominal height of the damper

D1 Hole base: see table above

D2 Hole height: see table above

E Damper protrusion from the wall: see table above

1. Rock wool panel 50 mm thick with 140 kg/m³ density.

2. PROMASTOP E PASTE or HILTI CFS-S ACR type sealant

3. PROMASTOP E PASTE or HILTI CFS-CT endothermic varnish

4. Wall indicated in the table

Installation within oor with Fire Batt (Weichschott) sealing

Refer to the section Construction supports characteristics for further

information.

Comply with the minimum distances indicated on section Minimum

distances

Floor opening

A opening must be provided in the oor as indicated in the table

and in the drawing

Damper positioning

Position the damper in the opening so that the side of the closing

mechanism extends as indicated in the table and in the drawing.

Filling

Fill the space between the damper and the oor using Fire Batt

(Weichschott) sealing made from two rock wool panels with mini-

mum thickness of 50 mm and minimum density of 140 kg/m³.

The panels must be covered on both faces of the wall with endo-

thermic varnish type PROMASTOP E PASTE or HILTI CFS-CT (mini-

mum thickness of 1 mm) and with an internal perimeter sealant type

PROMASTOP E PASTE or HILTI CFS-S ACR (minimum thickness of 1

mm).

Fire resistance classication

Hole size “D1 x D2”

[mm]

Damper protrusion from the

oor “E”

[mm]

Floor minimum thickness “S”

[mm]

Sealing

EI 120 S Installation within oor and Fire Batt (Weichschott) sealing

Floor minimum density 650 kg/m³

EI 120 S

(300 Pa)

(B+800 max) x (H+800

max)

185 150

Rock wool 140 kg/

m³ and endothermic

varnish sealing

B Nominal base of the damper

H Nominal height of the damper

Loading...

Loading...