HSLG Slide Gate Operator Installation Guide - 5 - P1220 Revision X8 6-22-2011

Operator Setup

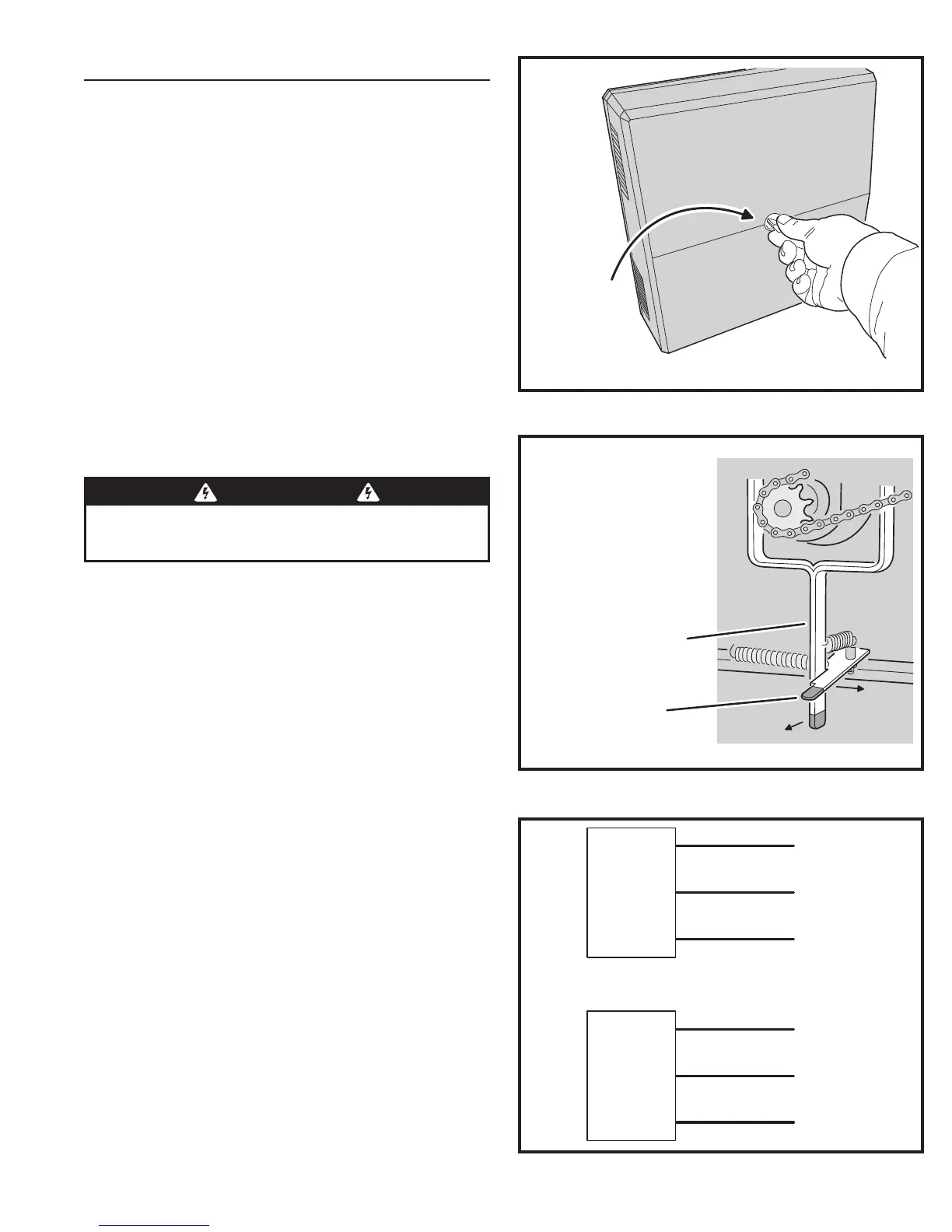

Controller Access

The Controller is protected by a plastic dust cover (single

phase models only). To remove the dust cover, loosen the

cover’s wing-screw and lift the cover off (see Figure 6).

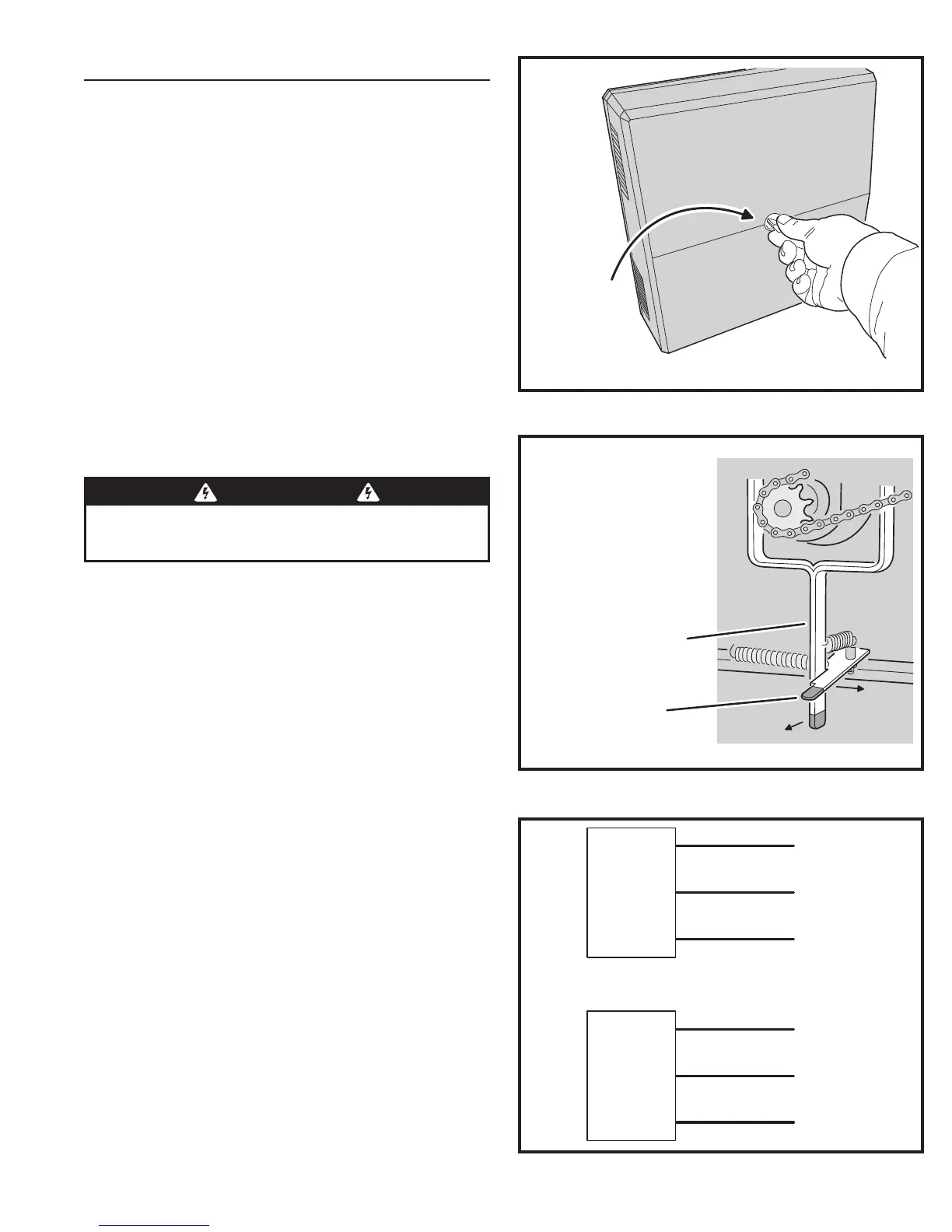

Manual Disconnect

The manual disconnect shifter lever and the locking lever

is illustrated in Figure 7. They can be found at the center

bottom of the operator cabinet. (The handle of each has

been fi nished in easy to spot red fi rm-grip coating.)

To disconnect the unit for manual operation, grasp the

handle of the spring-loaded shifter lever and pull it directly

toward you until the spring-loaded locking lever snaps into

place behind it. This action disengages the pinned shifter

block from the drive mechanism and holds the block in the

disengaged position.

To re-engage the operator, move the locking lever to the

right, releasing the spring-loaded shifter lever to snap back

into the engaged position.

AC Power Connection

All Linear gate operators are supplied with a power

disconnect switch to turn on and off the power available

to the operator. Following wiring specifi cations on Page 2,

incoming power should be brought into the operator and

connected to the labeled pigtails from the disconnect box.

A wiring connections print can also be found on the label

inside the cover of the operator.

Proper thermal protection is supplied with the operator. The

motor contains a thermal overload protector to guard from

overheating the motor due to overload or high-frequency

operation. This overload protector will reset automatically

after the motor cools down.

Earth Ground

Install a ground rod and connect it to the operator’s frame

in every gate operator installation. A good earth ground

is necessary to allow the Controller’s built-in surge and

lightning protection circuitry to work effectively. The physical

bolting of the operator to the mounting posts is not suffi cient

for a good earth ground.

✓ NOTE: Do not splice the ground wire. Use a single piece of solid

copper 12 AWG wire between the ground rod and the operator.

1. Install an 8-foot long copper ground rod next to the operator mounting

pad within three feet of the operator.

2. Use a clamp to connect a solid copper 12 AWG ground wire to the

ground rod.

3. Route the ground wire to the operator.

4. Connect the ground wire to the operator’s frame.

Figure 8. Power Disconnect Box Wiring

110 VOLT

OPERATOR

POWER

DISCONNECT

BOX

BLACK

220 VOLT

OPERATOR

POWER

DISCONNECT

BOX

WHITE

GREEN

BLACK

WHITE

GREEN

HOT

NEUTRAL

GROUND

HOT

HOT

GROUND

Figure 6. Controller Access

LOOSEN KNOB

TO REMOVE

CONTROLLER

COVER

WARNING

ALL AC ELECTRICAL CONNECTIONS TO THE POWER SOURCE AND

THE OPERATOR MUST BE MADE BY A LICENSED ELECTRICIAN AND

MUST OBSERVE ALL NATIONAL AND LOCAL ELECTRICAL CODES

Figure 7. Manual Disconnect Lever

MANUAL DISCONNECT

SHIFTER LEVER

PULL TO DISENGAGE

LOCKING LEVER

PUSH TO RIGHT TO

RE-ENGAGE OPERATOR

TO MANUALLY MOVE THE GATE,

PULL SHIFTER LEVER TO

DISENGAGE THE DRIVE TRAIN

GATE LIMIT SETTINGS WILL

NOT BE AFFECTED WHEN

GATE IS MANUALLY MOVED

PUSH

PULL

Loading...

Loading...