HSLG Slide Gate Operator Installation Guide - 6 - P1220 Revision X8 6-22-2011

Operator Setup (Cont.)

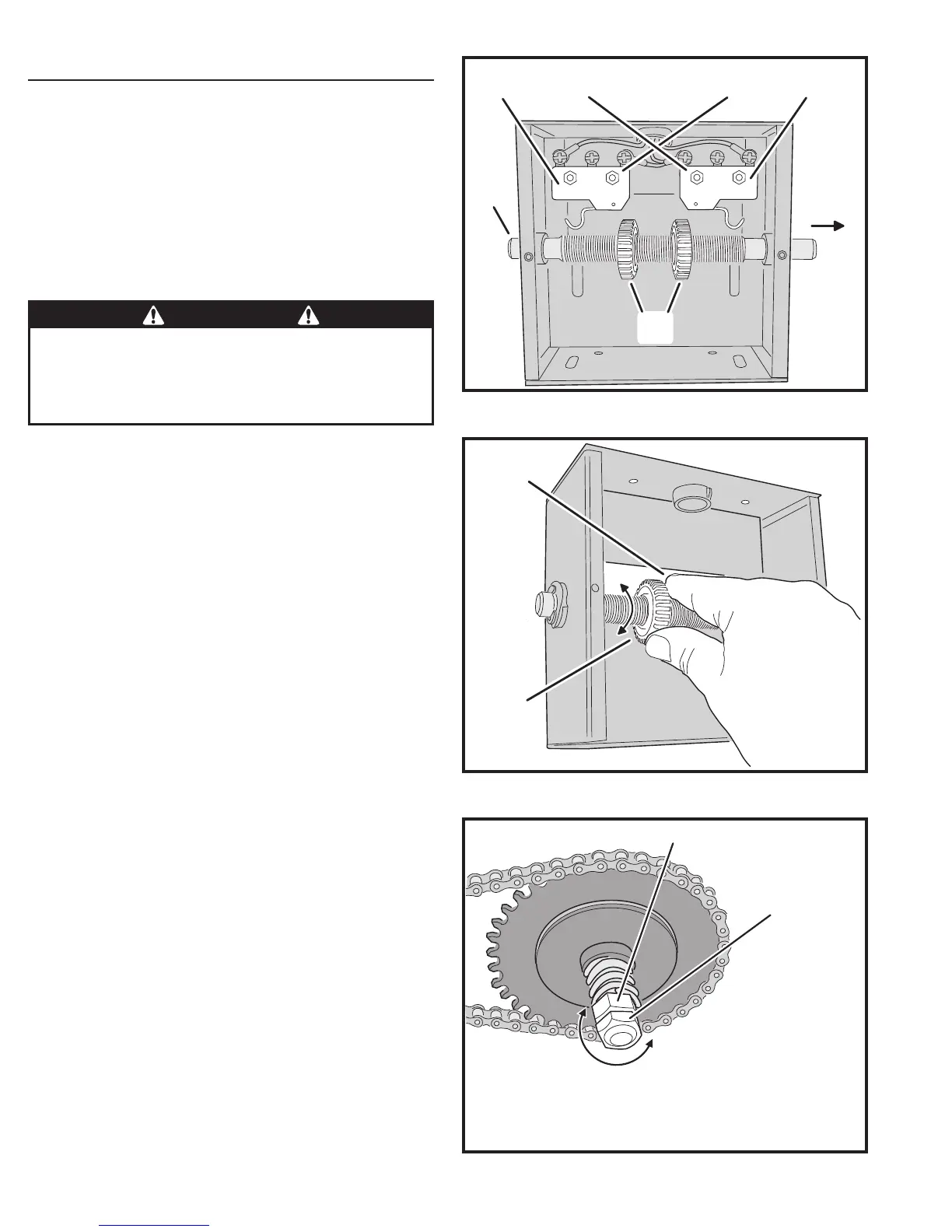

Open and Close Limit Adjustment

The limit nuts are not preset at the factory and must be adjusted

for the gate in each installation. The limit switches are activated

by two threaded nylon rotary limit nuts which are attached to

a threaded limit shaft driven by a chain and sprockets from

the main drive shaft. REMOVE THE CARDBOARD FILLER

BEFORE ADJUSTING THE LIMIT NUTS.

The Controller is factory setup for right hand installations.

The OPEN limit switch is the one closer to the front of the

operator. In left hand installations, the CLOSE limit switch is

the one closer to the front of the operator (see Figure 9).

Limit Nuts Rough Adjustment

Before running the operator, set the limit nuts as follows:

1. With the gate connected to the gate operator in a mid-travel position,

the power disconnect switch turned OFF, disconnect the operator

by using the manual disconnect lever, once the operator has been

disconnected, manually move the gate by hand to within a foot of

its fully open position (the foot of distance is necessary to allow for

coasting of the operator after the limit switch is tripped).

2. Once the gate is in this position, adjust the OPEN limit nut until it

activates the limit switch for open. Press down the detent plate and

rotate the nut along the threaded shaft (see Figure 10).

3. After setting the open limit, move the gate to one foot from fully

closed and repeat the process for the CLOSE limit nut.

Limit Nuts Fine Adjustment

After fi nishing the rough limit nut adjustments, reposition the

gate to approximately the center of travel.

1. Re-engage the operator using the disconnect handle.

2. Turn the power disconnect switch ON.

3. Stand clear of any moving parts and press the OPEN button.

4. After the gate opens, press the CLOSE button.

5. Observe the gate in both directions as it runs through each complete

cycle. Adjust the open or close limit nuts again if necessary. Fine levels

of adjustment can be made by adjusting a few teeth on the nut at a

time. If the gate stops during travel, you may need to adjust the Open or

Close Current Setting or the Maximum Run Timer (see Pages 12-13).

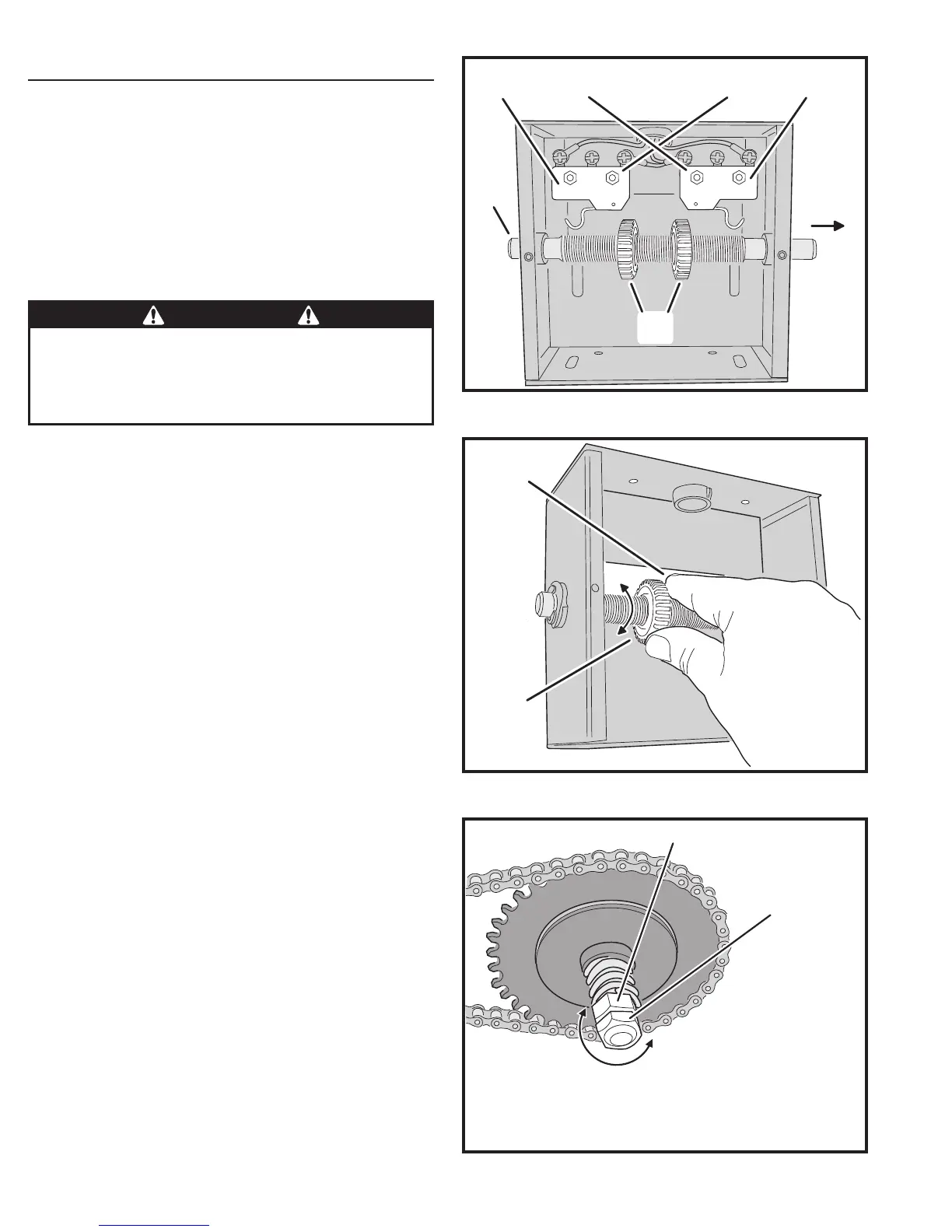

Torque Limiter Adjustments

Before adjusting the torque limiter, make sure the gate is in

good working condition. One person should be able to move

the gate by hand. Be certain the gate moves freely and

without binding throughout its travel. Torque limiters are set

light at the factory and must be adjusted during installation.

Adjust the torque limiter tight enough to keep it from slipping

during normal operation. See Figure 11.

To adjust the torque limiter in model HSLG:

1. Loosen the jam nut.

2. To increase the output, turn the adjustment nut clockwise

one fl at, or 1/6 turn, at a time until desired output is obtained.

To reduce the output, turn the adjustment nut counterclockwise one

fl at, or 1/6 turn, at a time until desired output is obtained.

3. Tighten the jam nut against the adjustment nut when fi nished.

PRESS DETENT

PLATE DOWN

ROTATE

LIMIT NUT

Figure 10. Setting the Limits

Figure 11. Torque Limiter Adjustment

CAUTION

If the operator is installed in a left-hand installation. Set the

Controller to left-hand operation BEFORE running the operator

for the fi ne setting of the limit nuts. Failure to do so will result

in over-shooting the limit switches, and can cause damage to

the operator and/or gate. Refer to programming on Page 11.

LEFT-HAND INSTALLATION

OPEN LIMITCLOSE LIMIT

RIGHT-HAND INSTALLATION

OPEN LIMIT CLOSE LIMIT

LIMIT

NUTS

LIMIT

SHAFT

LIMIT

SWITCHES

FRONT OF

OPERATOR

Figure 9. Limit Box Assembly

ADJUSTMENT NUT

JAM NUT

TO INCREASE TORQUE

TURN ADJUSTMENT NUT

CLOCKWISE ONE FLAT

THEN RE-TEST

TO DECREASE TORQUE

TURN ADJUSTMENT NUT

COUNTERCLOCKWISE

ONE FLAT THEN RE-TEST

MORE

LESS

TIGHTEN JAM NUT

DURING TESTING

AND WHEN FINISHED !!!

Loading...

Loading...