10

4.2 Checking the battery

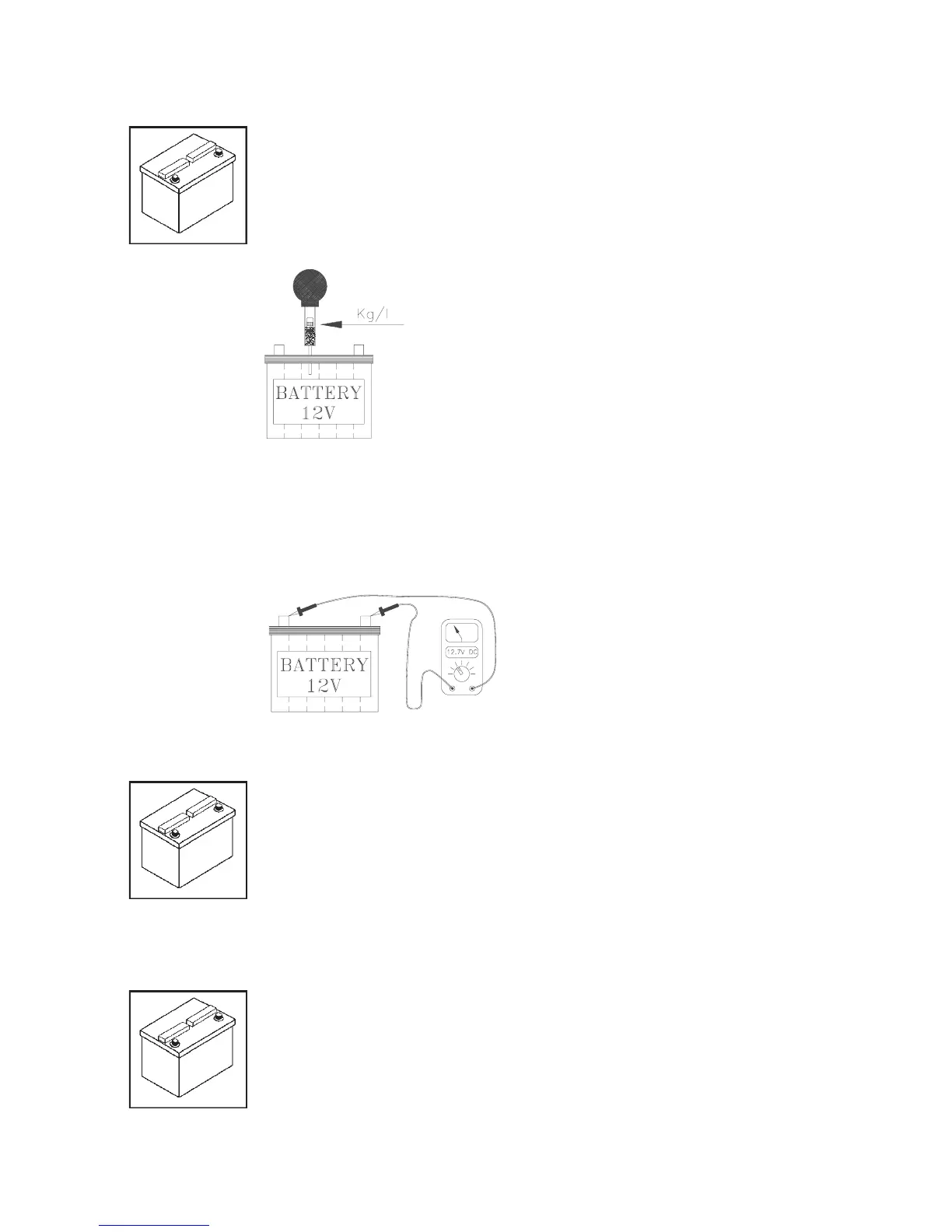

Method A for SEMI-TRAK and TUBULAR CELL:

Check acid density in the six battery cells with an acidometer.

Check each cell - max. difference between each cell 0.04 kg/l.

DENSITY

1.26 - 1.28 kg/l Fully charged

1.19 - 1.20 kg/l 1/2 charged

1.16 - 1.17 kg/l 1/4 charged

1.10 - 1.11 kg/l Discharged

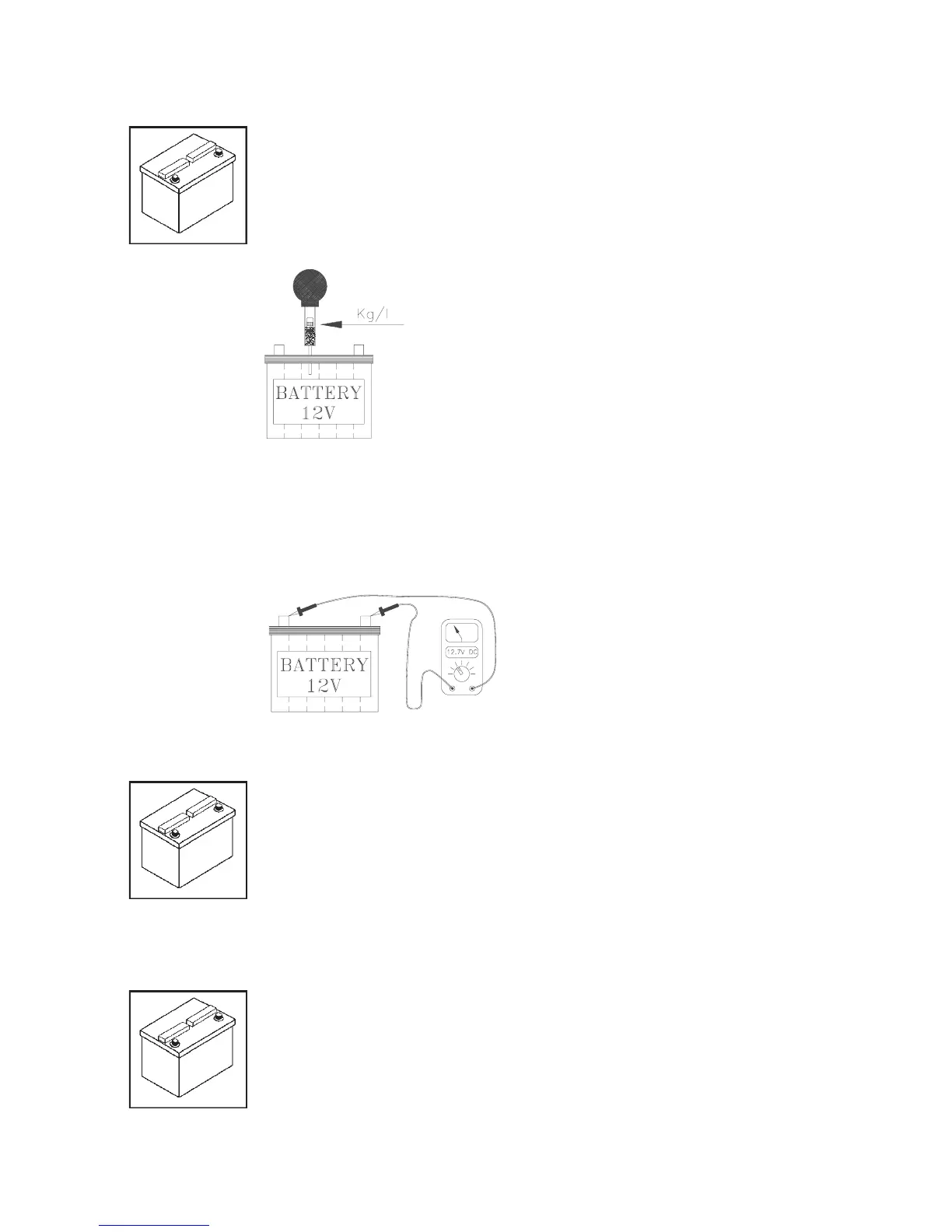

Method B for all three battery types:

To measure the voltage, use a digital voltmeter (DC) on the battery

poles. The truck must not have been in use for the previous 30

minutes.

Approx. 12.7 V Fully charged

Approx. 12.2 V 1/2 charged

Approx. 12.0 V 1/4 charged

Approx. 11.6 V Discharged

4.3 Battery charging

Charging must be performed with a charger correctly set with the

charging voltage for the battery type, see point 4.1.

The manufacturer recommends a charger of 10-15 amp capacity.

During charging, the temperature in the battery must not exceed

50° C.

Charging simultaneously with truck operation is not advised.

4.4 Warnings and information on battery

Avoid the use of naked flame in the vicinity of tubular cell and

Semi-Trak batteries.

The charging of tubular cell and Semi-Trak batteries gives off gases

that can be explosive. Therefore charging should be performed in a

ventilated room.

At temperatures around freezing point, battery capacity is reduced

by 30%.

Loading...

Loading...