LogTag UTRIX Work Instruction Manual Revision 1.07 MP Release Page 10/52

1.3 Crystal mounting

The 32khz crystal is very fragile, excess mechanical stress and heat can cause it to fail or go intermittent.

Care must be taken during this process to not put any mechanical stress onto the legs of the crystal or to

apply to much heat during soldering.

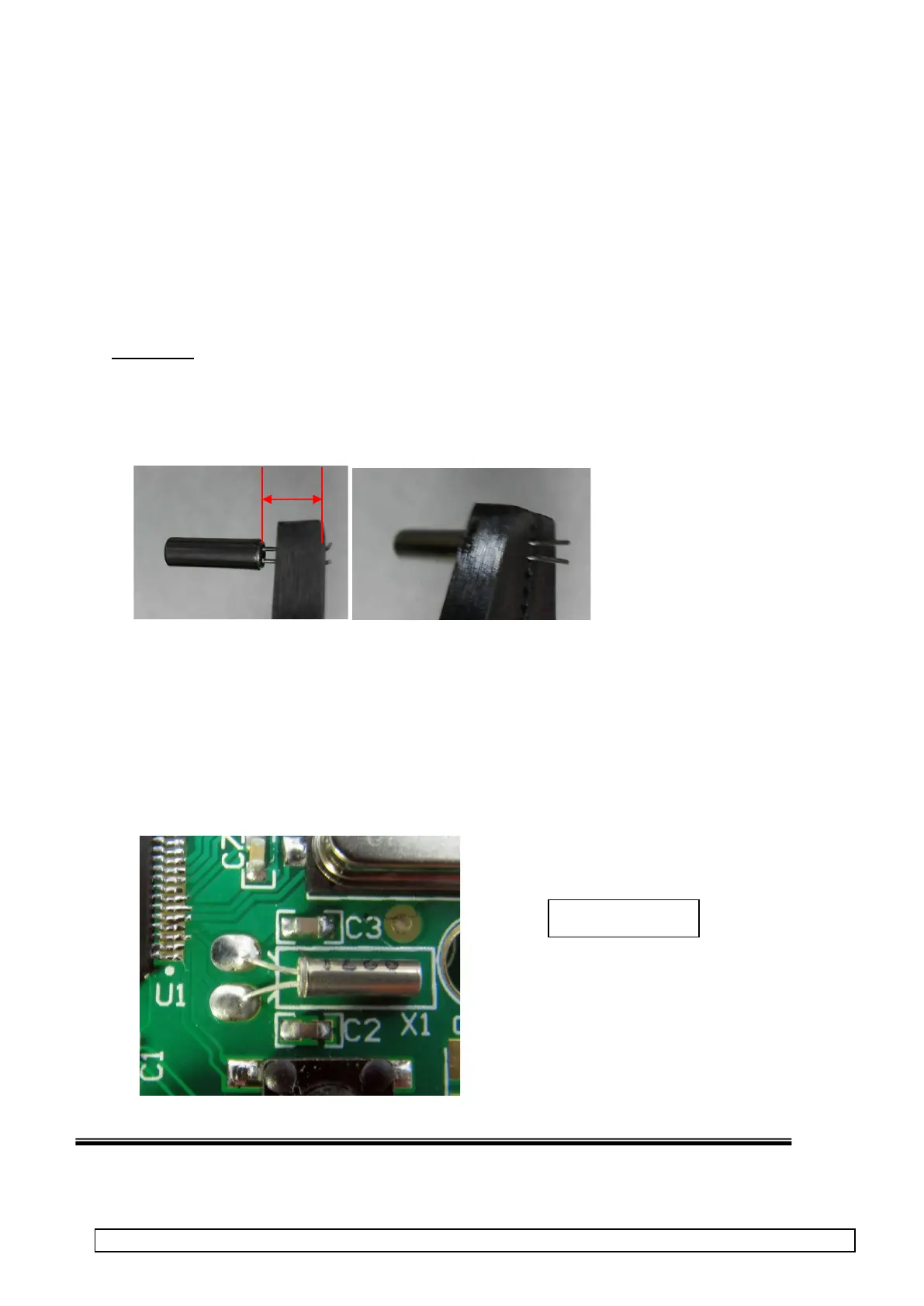

Mount 32768Hz crystal onto the PCB as shown.

Crystal is top soldered with legs passing into holes and flush trimmed on other (non-copper) side of PCB. No

more than 0.3mm of cut off length must remain.

NOTE: DO NOT RTV crystal at this step.

Procedure:

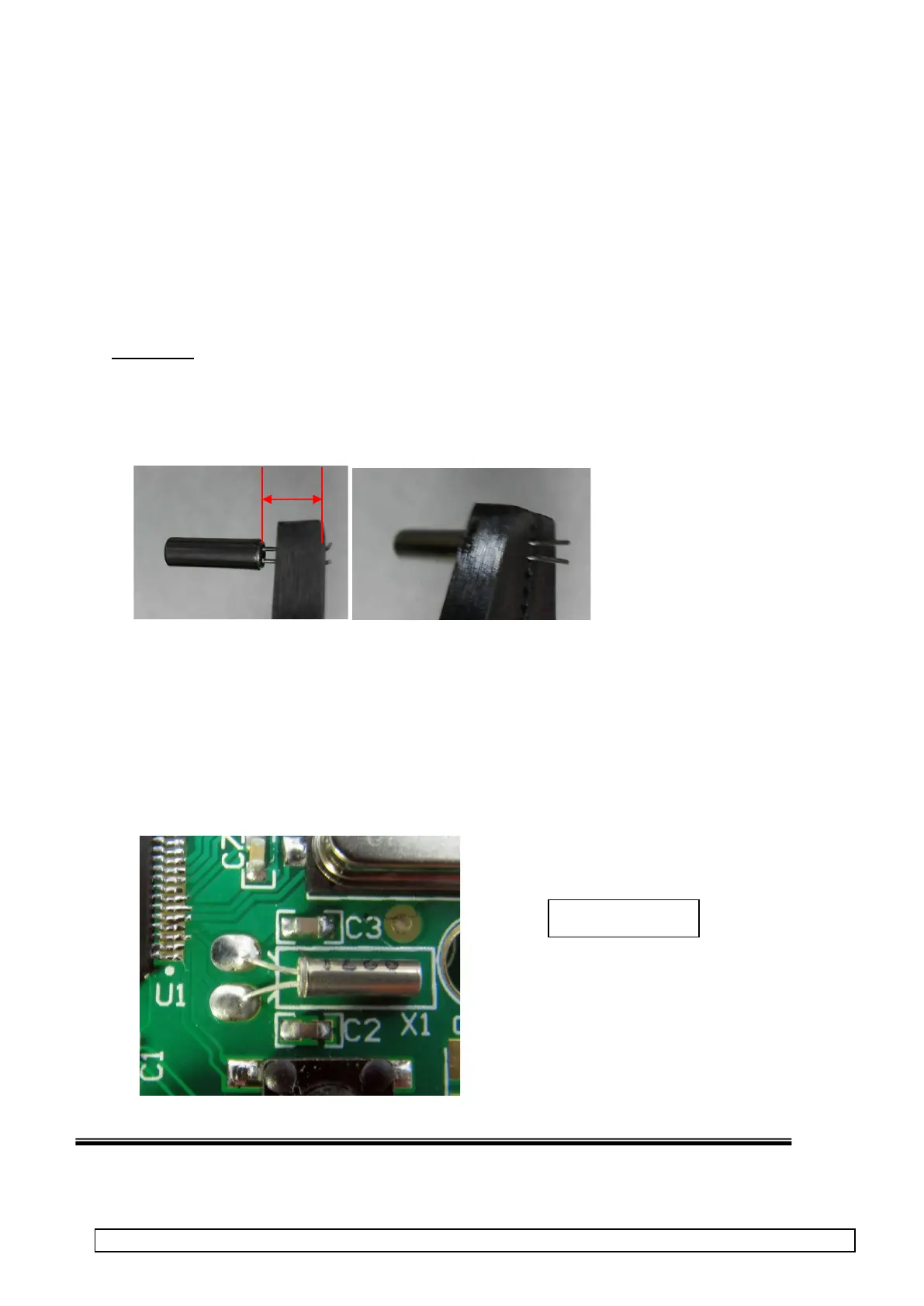

1. Trim the crystal leads to 5mm.

2. Using a bending tool or plyers, hold the legs of the crystal and bend them to 90° 3.5mm from the crystal

body as shown. At no time place any stress to the crystal or where the legs enter the crystal body.

3. Place the crystal onto PCB.

4. Solder the legs of crystal. Do not apply excessive heat or solder!

Solder joint should be shiny and fully wetted with no excess solder.

The crystal soldering according to the following condition (only legs of the crystal):

• Keep the Soldering Iron temperature at an optimum temperature to solder the joints but to minimise

overheat of the crystal component

• Soldering for 5 seconds maximum.

Loading...

Loading...