Do you have a question about the Lombardini 5LD825-3 and is the answer not in the manual?

Detailed technical specifications and dimensions for various engine models.

Performance graphs showing power, torque, and fuel consumption characteristics.

Intervals and operations for engine cleaning, checking, and component replacement.

Guidance on suitable oil types and fluid capacities for the engine.

Table listing common engine problems, their possible causes, and troubleshooting steps.

Technical drawings with detailed measurements for engine models.

Technical drawings with detailed measurements for engine models.

Specific torque values for various engine components and fasteners.

Torque data for standard bolts based on grade and size.

Guide on applying specific sealants for engine assembly and maintenance.

Procedures for cleaning and replacing air filter elements and components.

Instructions for removing and installing exhaust and intake manifolds, and fan belts.

Steps for servicing the flywheel, cylinder, and piston components.

Procedures for adjusting valve clearance, rocker arms, and valve springs.

Instructions for the alignment, weight, bearing, and removal of connecting rods and crankshaft.

Procedures for camshaft removal, bearing checks, and timing adjustments.

Procedures for hydraulic pumps, speed governors, and turbochargers.

Diagrams illustrating the routing of oil passages and components within the engine.

Details on the oil pump, filter replacement, and pressure relief valve operation.

Procedures for checking oil pressure and interpreting pressure curves at different speeds.

Overview of the fuel system components and their arrangement.

Detailed breakdown of injection pump parts and procedures for delivery testing.

Steps for setting and correcting static and dynamic injection timing.

Information on injector components, nozzle features, and setting injection pressure.

Diagrams showing wiring for starting systems with and without battery charging light.

Specifications and charging curves for different alternator models.

Procedures for checking voltage regulator function and cable continuity.

Characteristic curves and details for Bosch JF series starting motors.

Procedures for adjusting idling and full speed settings in no-load conditions.

Method for setting injection pump delivery using a torque dynamometer.

Steps to correctly set the engine stop mechanism.

Guidelines for protecting the engine during short-term storage (1-6 months).

Additional measures for long-term engine storage (over 6 months).

Steps to safely return a stored engine to operational status.

Tools for removing the flywheel and timing control gears.

Tools for servicing valve springs and setting injection pump timing.

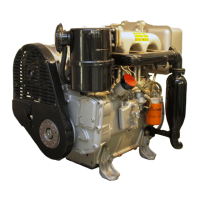

| Brand | Lombardini |

|---|---|

| Model | 5LD825-3 |

| Category | Engine |

| Language | English |