Do you have a question about the Lombardini 9LD561-2 and is the answer not in the manual?

Instructions for checking, cleaning, and refitting the oil-bath air cleaner.

Instructions for cleaning and noting replacement for the dry air cleaner.

Components and calibration details for the clogging indicator.

Instructions for cleaning and refitting the oil vapour separator.

Checks for warpage, alignment, and gasket replacement for the intake manifold.

Checks for cleanliness, alignment, and gasket replacement for the exhaust manifold.

Components and material properties of the pulley guard assembly.

Instructions for cleaning, checking, and replacing the cooling fan blades.

Components and torque specification for refitting the hub.

Instructions for removing and refitting the alternator stator and bolts.

Instructions for removing and refitting the shroud support, checking seals.

Instructions for removing the fuel tank, checking for impurities, and refitting.

Instructions for removing and refitting the flywheel and starter ring gear.

Procedure for setting valve clearance when the engine is cold.

Procedure for measuring and setting compression release clearance.

Components, dimensions, and refitting checks for the rocker arm assembly.

Cleaning, checking protrusion, and tightening fixing nuts for the injector.

Procedure for adjusting injector projection using shims.

Instructions for removing, checking for warpage, and refitting the cylinder head.

Components and procedure for removing valves and half collets.

Procedure for measuring free length and checking valve springs under load.

Material specifications for intake and exhaust valves.

Components, dimensions, and available oversize options for valve guides.

Procedure for heating and pressing valve guides into the cylinder head.

Specifications for valve guide and valve dimensions and clearances.

Dimensions for valve seats and housings, and pressing procedure.

Procedure for grinding valve seats and checking worn limits.

Refitting check for gaskets and lubrication tube on the pushrod tube.

Procedure for measuring cylinder diameter and checking wear.

Checks for cylinder porosity, leakage, and cross-hatch pattern.

Procedure for removing circlips, piston pin, and piston rings.

Weighing pistons to avoid unbalance during replacement.

Procedure for measuring piston ring end gaps.

Specifications for piston ring groove clearances.

Recommended sequence for fitting piston rings.

Procedure for fitting the piston to the connecting rod and cylinder.

Procedure for measuring piston clearance using gaskets.

Procedure for removing connecting rods and checking them.

Dimensions and clearance specifications for the small end bushing.

Procedure for checking and correcting connecting rod alignment.

Weighing connecting rods to avoid unbalance.

Refitting instructions and torque for the big end bearing.

Tools and procedure for removing the crankshaft timing gear.

Procedure for removing the main bearing support on the gear side.

Procedure for removing the main bearing support on the flywheel side.

Locating bolt removal for crankshaft.

Procedure for removing the crankshaft using a hammer.

Refitting instructions for the center main bearing support.

Procedure for cleaning crankshaft lubrication ducts.

Specifications for crankshaft journal radii.

Using an outside micrometer to check main journals and crank pins.

Using an inside micrometer to measure main bearing diameter.

Dimensions for main and connecting rod bearings.

Specifications for bearing clearances.

Dimensions for flywheel side, central, and gear side main bearing supports.

Dimensions for main bearing housings.

Checking and setting crankshaft end play using gaskets.

Measuring camshaft journals and housings.

Specifications for camshaft journal and housing dimensions.

Specifications for camshaft journal and housing clearances.

Procedure for measuring intake and exhaust cam height.

Checking camshaft end play with a dial gauge.

Procedure for fitting the camshaft gear and tightening the bolt.

Procedure for setting valve timing without using timing marks.

Procedure for checking valve timing at the crankshaft.

Components and torque/HP rating of the 1P hydraulic pump PTO.

Operation and components of the weight-type governor in the camshaft drive gear.

System features two springs for RPM control at low speeds.

Device for automatically providing extra fuel during starting.

Introduction to the optional electronic speed governor.

Components of the electronic speed governor system.

Explanation of the electronic speed governor components and operation.

Procedure for starting the engine with an electronic speed governor.

Operation of the engine with an electronic speed governor.

Details on the setscrews for the electronic speed governor control box.

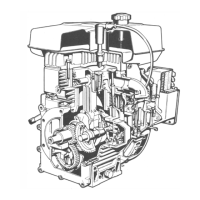

Diagram showing the components of the lubrication system.

Checks for oil pump gear teeth, clearance, and shaft end float.

Components and features of the internal oil filter cartridge.

Components and procedure for checking the oil pressure relief valve.

Procedure for checking oil pressure using a gauge.

Graph of oil pressure vs. temperature at idling speed.

Graph of oil pressure vs. temperature at full speed.

Diagram of the fuel feeding and injection circuit components.

Components of the fuel filter located inside the fuel tank.

Operation and characteristics of the diaphragm fuel feeding pump.

Procedure for adjusting fuel pump drive rod protrusion.

Description of the Bosch injection pump system.

Description of the plunger and barrel assembly.

Procedure to check for internal leakage in plungers and barrels.

Procedure to check injection pump delivery valve sealing.

Test data for injection pump delivery for different engine models.

Procedure for reassembling injection pump components.

Procedure for mounting the injection pump onto the engine.

Procedure for timing the injection pump and mechanical speed governor.

Disconnecting the injection line and attaching the timing tool.

Components and dimensions of the injection timing checking device.

Procedure for checking static injection timing.

Explanation of reference marks for injection timing.

Location and purpose of the reference mark check window.

Procedure for correcting injection timing using shims.

Components of the injector.

Features of the injector nozzle.

Procedure for checking and setting injector pressure.

Standard electric starting layout without battery charging light.

Electrical starting layout with battery charging light.

Features and dimensions of the 12.5V, 14A alternator.

Graph showing the alternator's charging curve.

Tool and procedure for checking alternator magnetization.

Procedure to check cable continuity and insulation.

Information on LOMBARDINI, SAPRISA, and DUCATI voltage regulators.

Procedure for checking the voltage regulator's operation.

Optional electrical equipment details.

Details of the 12V, 18A alternator.

Graph of the 12V, 18A alternator charging curve.

Information on the 12V, 24A special voltage regulator.

Description of the Bosch G1 14V, 33A alternator.

Wiring layout for the Bosch G1 14V, 33A alternator.

Charging curve for the 14V, 33A Bosch G1 alternator.

Introduction to starting motors made by Marelli and Bosch.

Details and dimensions of the Magneti Marelli E100 starting motor.

Performance curves for the Magneti Marelli E100 starting motor.

Details and dimensions of the Bosch GF 12V starting motor.

Performance curves for the Bosch GF 12V starting motor.

Details of the Bosch DW(R) 12V, 1.7kW starting motor.

Performance curves for the Bosch DW(R) 12V starting motor.

Procedure for setting the engine idling speed.

Procedure for setting full engine speed in no-load conditions.

Procedure for setting injection pump delivery at the torque dynamometer.

Explanation of delivery limiting and extra fuel device.

Detailed steps for setting injection pump delivery.

Table of required settings for various engine models.

Procedure for setting the engine stop mechanism.

Procedures for temporary engine protection for storage.

Recommendations for long-term engine protection.

Steps to prepare a stored engine for operation.

| Number of Cylinders | 1 |

|---|---|

| Fuel System | Direct injection |

| Lubrication System | Forced lubrication with gear pump |

| Engine Type | Diesel |

| Cooling System | Air |

| Starting System | Electric start |