25

Chapter VII Trouble shooting of mini tiller

i. Trouble shooting of clutch (note: never try to detach the clutch assembly by your self, if you find any of the

malfunctions marked with ※ in the table below, please contact our company or the distributor)

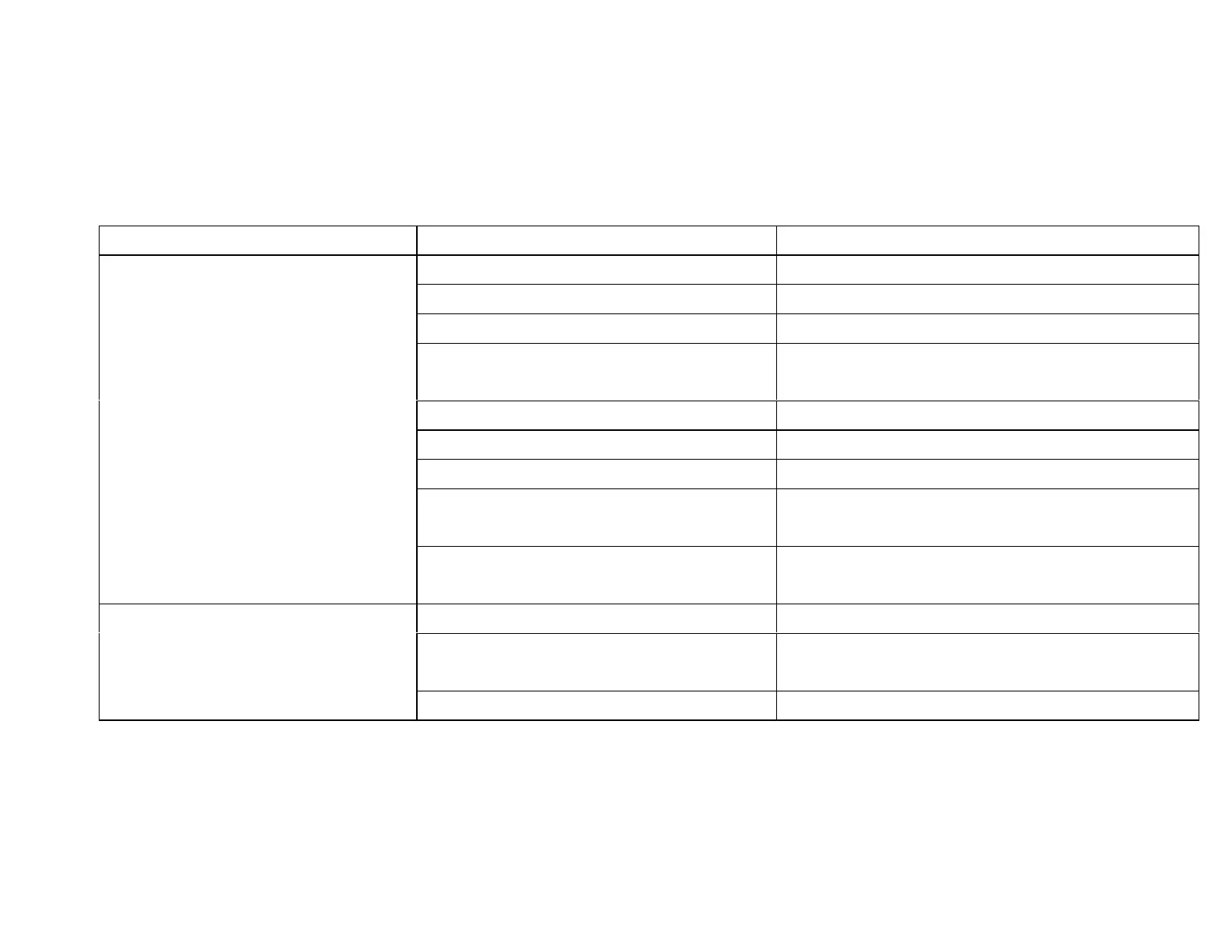

Phenomenon Cause Solution

Clutch handle fails Replace or repair clutch handle

Clutch cable is damaged Replace clutch cable

Clutch fork is not adjusted adequately Readjust clutch cable or replace clutch fork

Fork shaft falsl off from its welding

unction with arm seat

Replace or repair

Fork pin is broken of bent Replace fork pin

※Friction disk fails Replace friction disk

※Spring fails Replace spring

Friction disk set can’t contact bearing

face inside the clutch housing

Insert one washer or more of appropriate

thickness behind the bearing

Clutch unable to engage and

disengage

Bearing inside clutch is burnt out Replace bearing and if necessary, add oil into

transmission box

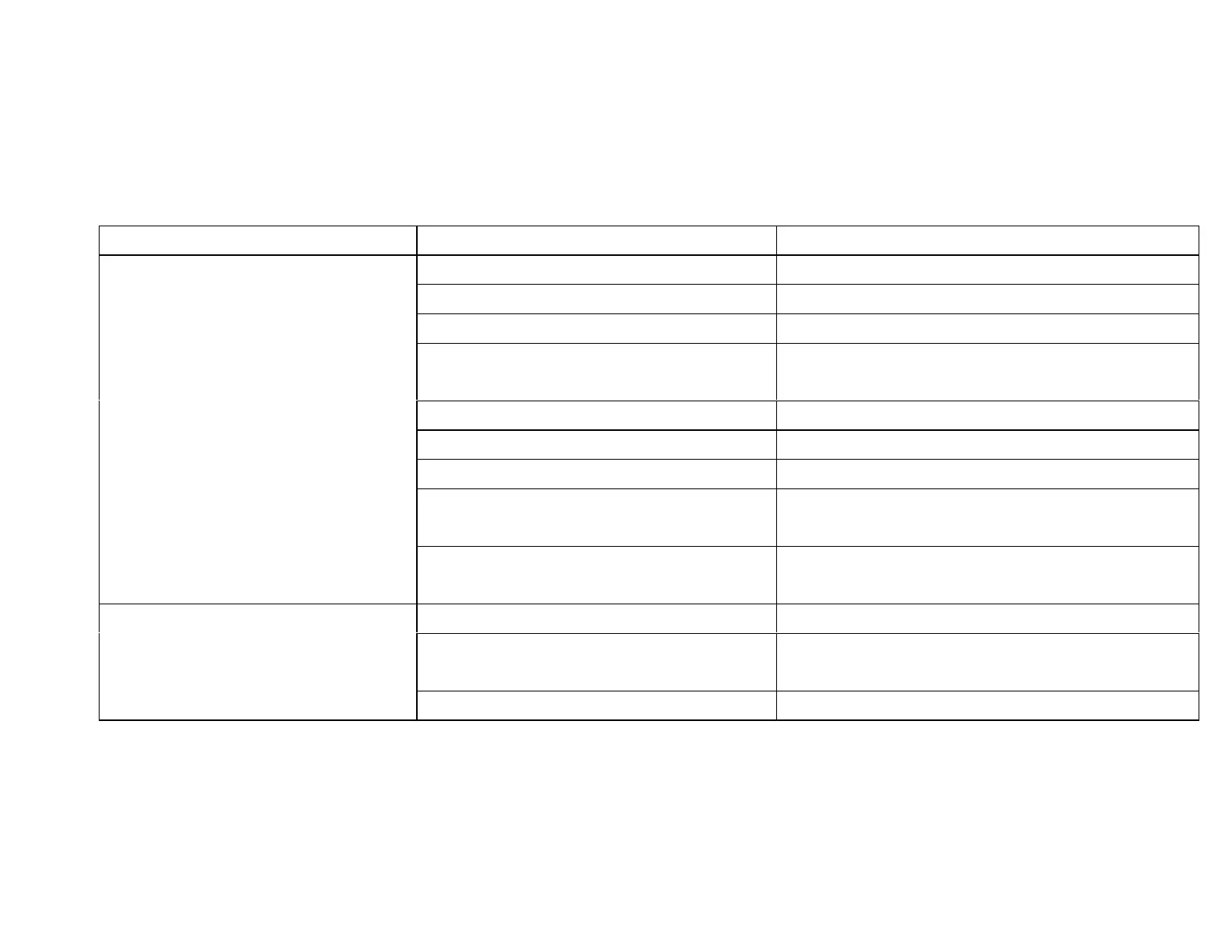

※Spring fails because of fatigue Replace spring

Fork shaft’s rotation is abnormal, or it

fails, causing uncompleted return of fork

Clean the junction surface between locating shaft

and pusher, to let rotation of fork shaft be easy

Skidding (when the operator firmly

grips clutch handle, engine runs

normally but transmission main shaft

rotates slowly or doesn’t rotate.

Clutch cable is adjusted inappropriately Readjust clutch cable

Loading...

Loading...