8

4 Automatic Control For Full-Tank Shutoff

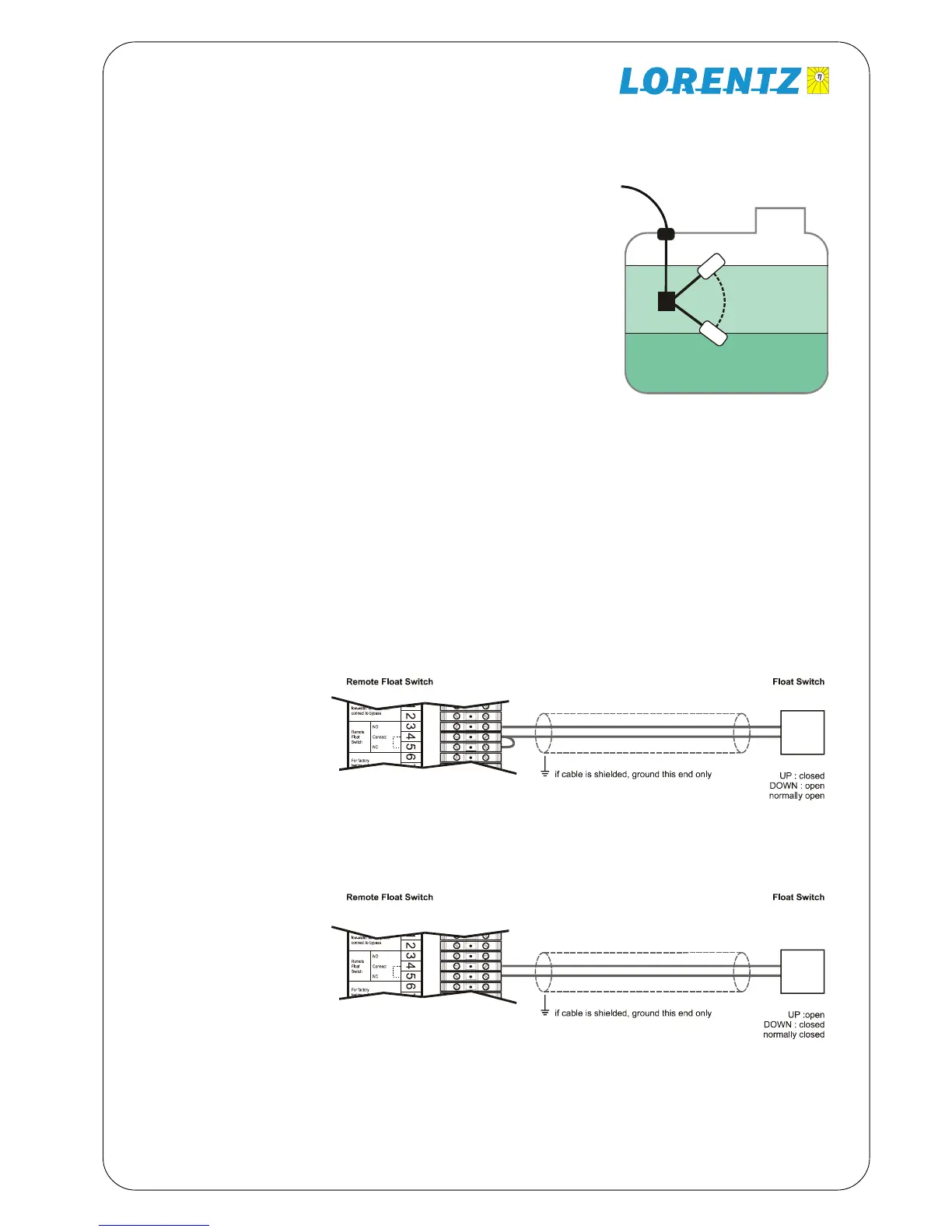

We recommend the use of a float switch or

other means to prevent overflow of your tank.

This will stop the pump when the tank is full,

then reset when the level drops. This con-

serves ground water, prevents overflow, and

eliminates unnecessary pump wear. PS-XXX

controllers allow the use of small signal cable

to a remote float switch, even if the tank is a

long distance away.

Float switch requirements

1. A switch must be used, not wet electrodes.

2. The preferred system requires a float

switch to MAKE contact on rise to turn the

pump OFF. This is called “normally open”

(N.O.). It may be commercially labeled as a

“pump down” switch, but here it works in

reverse, to allow pumping up.

sealed

cable clamp

cable

weight

pump off

pump on

pumping

range

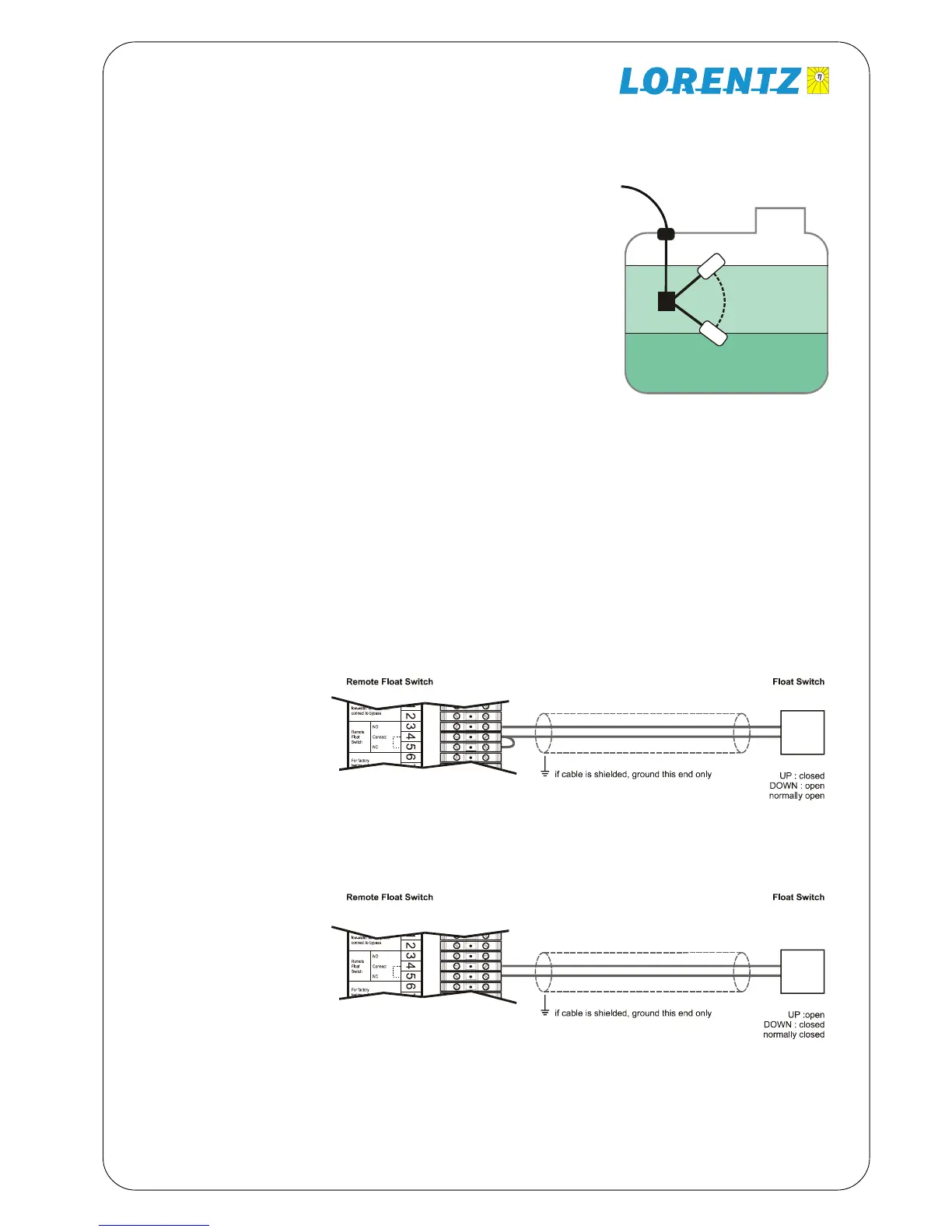

Wiring to the controller

The controller offers two

options for connection of a

remote switch. These allow

the use of either a

“normally open” (N.O.) or

a “normally closed” (N.C.)

switch. “Normal” refers to

the status of the contacts

when the switch is DOWN

and calling for water.

Float switch cable require-

ments

1. Two wires are needed.

2. Minimum wire size #18

AWG ( 1mm²). This is good

for a distance as far as 2000

feet (600 m).

3. The cable must be suitable

for its environment.

4. If it must run a long

distance, use twisted-pair

shielded cable to reduce the

chance of damage from lightning-induced

surge.

Grounding shielded float switch cable If

you use shielded cable, connect the shield to

ground AT THE CONTROLLER ONLY. DO

NOT ground the shield at the float switch.

This will reduce surges induced by nearby

lightning.

Wiring a “normally open switch” Connect the switch to terminals 3 and 4 (NO and

common) and connect terminals 4 and 5 together, as illustrated.

Closing (connecting) the switch circuit turns the pump OFF

Wiring a “normally closed/reverse action switch” Connect the switch to termins 4

and 5. Closing (connecting) the switch turns the pump ON

Manual PS600 BADU Top 12

Loading...

Loading...